Unveiling the Power of High Speed Thermal Imaging Cameras for Advanced Applications

Thermal imaging cameras have come a long way, and the new high-speed thermal imaging camera models are really something else. They can see things we just can't with our own eyes, like tiny heat differences that tell us if something's about to go wrong. This tech is showing up everywhere, from keeping factories running smoothly to helping out in defense. It’s pretty wild how much information a camera that sees heat can give us, making jobs safer and processes more reliable.

Key Takeaways

-

High-sensitivity thermal cameras can spot small temperature changes, which is great for checking product quality and making sure manufacturing is consistent.

-

These cameras have advanced features that make them useful for tough jobs like drone defense and critical aerospace systems.

-

The technology inside, like better sensors and smarter image processing, means clearer pictures and more reliable data, even when capturing heat and visible light at the same time.

-

Systems built for tough conditions need to handle wide temperature ranges and be built strong to work reliably in harsh places.

-

Adding AI directly into the camera helps process all that thermal data faster, right where the action is happening, making things more efficient.

Unlocking Precision with High-Sensitivity Thermal Imaging

Detecting Minute Temperature Differences for Quality Control

In manufacturing, even the smallest temperature variations can signal significant issues. High-sensitivity thermal cameras are designed to pick up on these subtle changes, offering a level of detail previously unattainable. This capability is particularly vital for quality control, where identifying minute thermal anomalies can prevent defects from reaching the end-user. For instance, in printed circuit board (PCB) manufacturing, these cameras can spot inconsistencies in solder joints or component heating that might indicate a potential failure. By providing real-time, high-resolution thermal imaging, they improve the accuracy and reliability of production processes, helping to reduce waste and uphold the highest product standards. This allows for meticulous inspection, catching even the smallest thermal deviations that could point to inefficiencies or flaws. Achieving unparalleled consistency and excellence in your products becomes more attainable with this advanced technology.

Achieving Unparalleled Consistency in Manufacturing

Consistency is the bedrock of reliable manufacturing. High-sensitivity thermal imaging systems contribute directly to this by offering precise and repeatable temperature measurements. This allows for the fine-tuning of processes that are highly dependent on exact thermal conditions. Whether it's ensuring uniform heating in an oven or monitoring the cooling rate of a molded part, these cameras provide the data needed to maintain tight tolerances. This level of control minimizes batch-to-batch variation, leading to a more predictable and dependable output. The ability to see and measure these fine thermal details means that manufacturers can establish and maintain optimal operating parameters with greater confidence, resulting in a more uniform and high-quality product line. This technology is a key component in achieving precise manufacturing outcomes.

Minimizing Thermal Noise for Superior Image Clarity

Thermal noise is an inherent challenge in infrared imaging, often obscuring subtle temperature details. High-sensitivity thermal cameras are engineered with advanced technologies to significantly reduce this noise. A key metric here is the Noise Equivalent Temperature Difference (NETD), where a lower value signifies better performance. Cameras with a low NETD can distinguish between objects with very similar temperatures, providing clearer images and more reliable data. This improved image clarity is not just about aesthetics; it directly translates to better detection capabilities. Whether identifying faint heat signatures in security applications or pinpointing minor temperature variations in industrial equipment, minimizing thermal noise allows operators to see more intricate details and make more informed decisions. This precision is what separates basic thermal imaging from advanced, mission-critical applications.

Advanced Capabilities for Demanding Applications

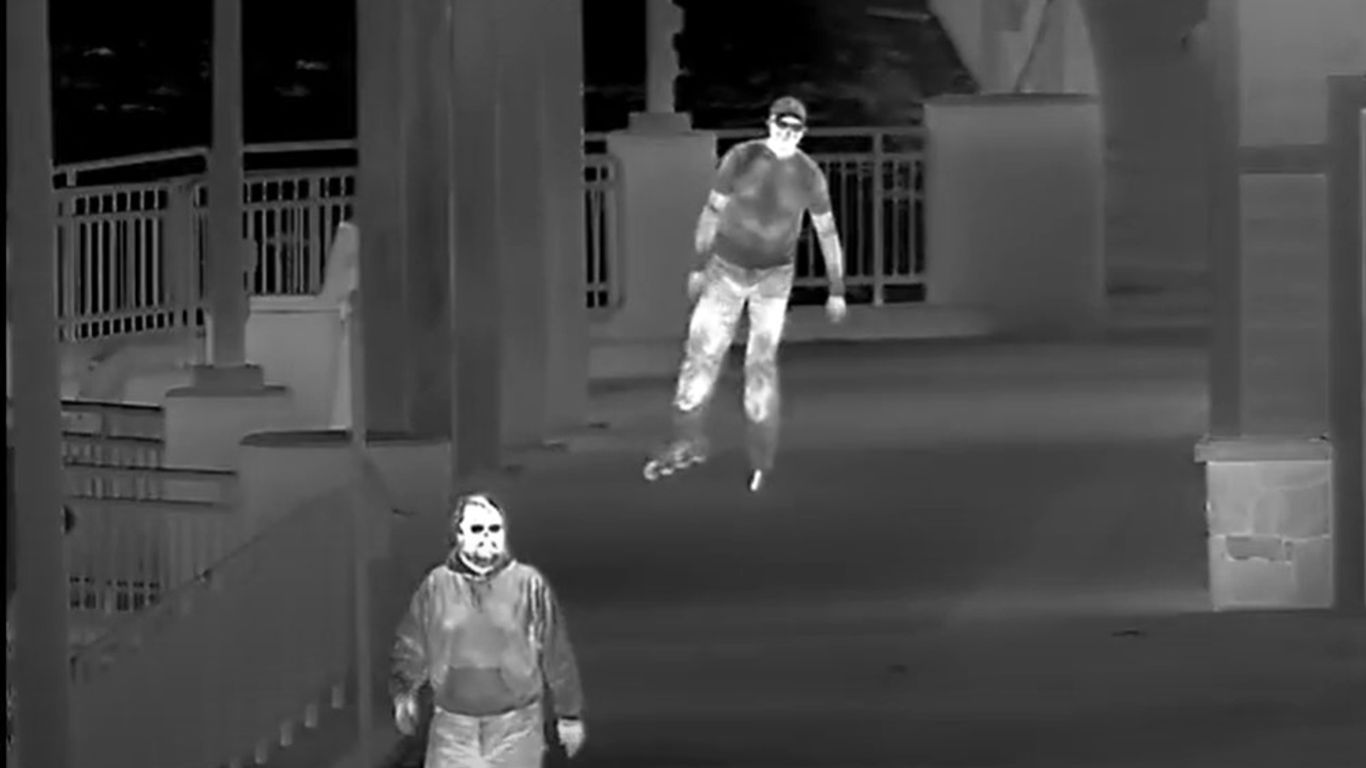

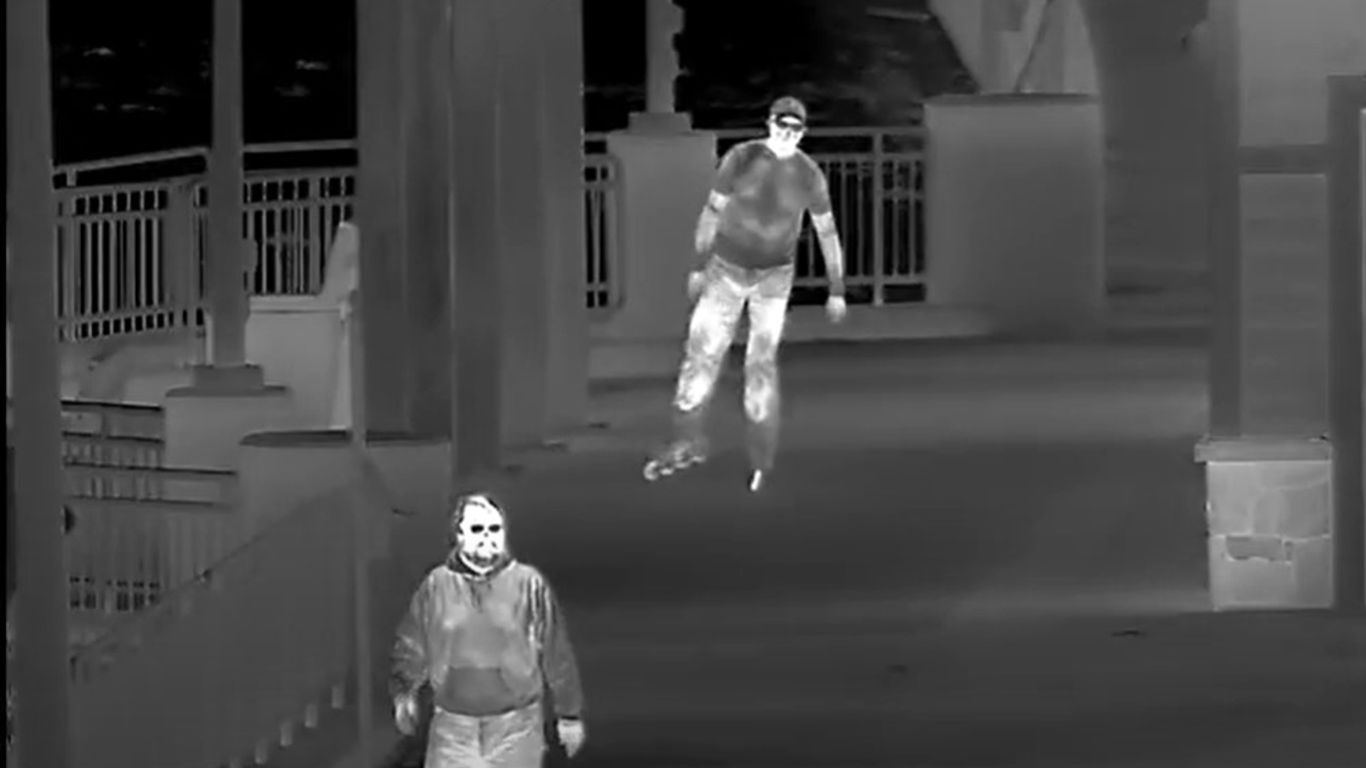

Counter-Unmanned Aircraft Systems Operations

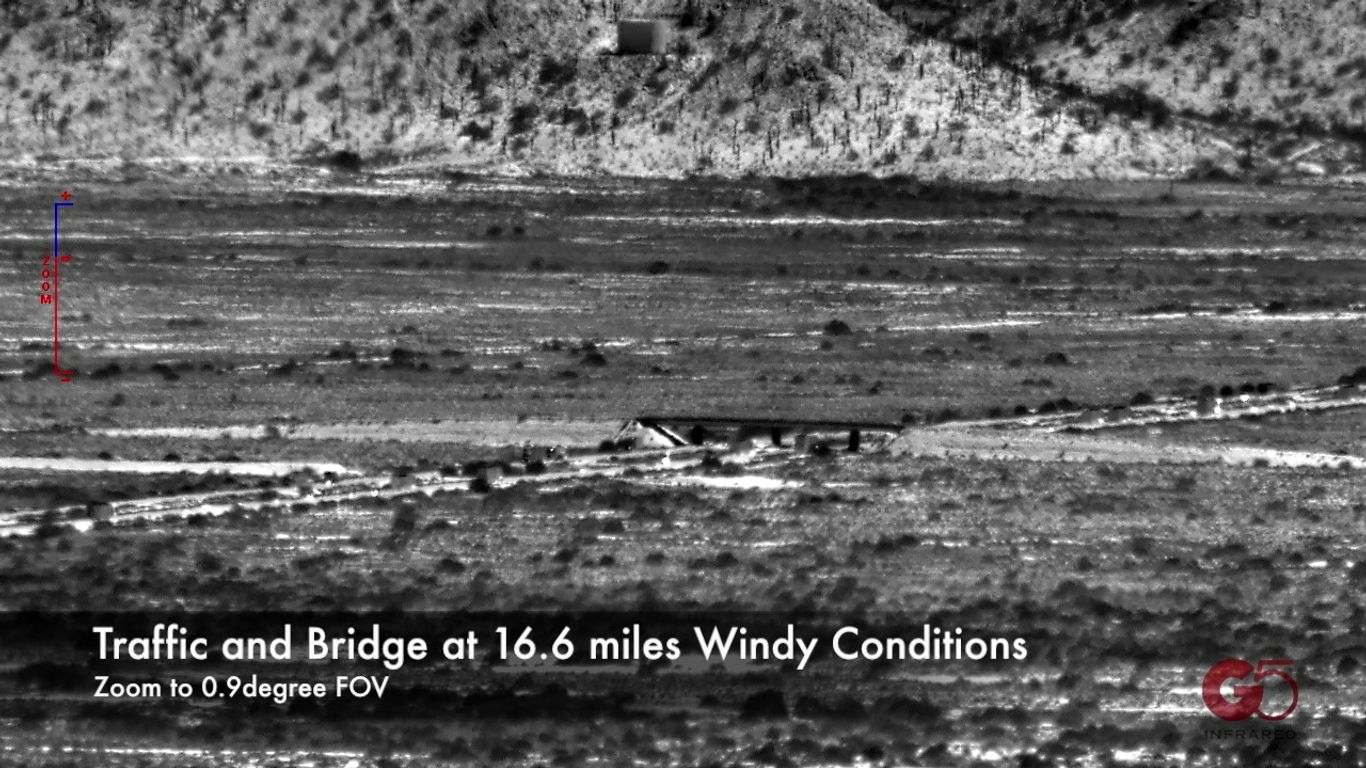

In today's security landscape, the proliferation of unmanned aircraft systems (UAS) presents a significant challenge. High-speed thermal imaging cameras offer a distinct advantage in Counter-UAS (C-UAS) operations by providing persistent, all-weather detection capabilities. These systems can identify the thermal signature of drones, even when they are small, distant, or operating against complex backgrounds. The ability to distinguish between a drone and other environmental thermal noise is paramount for accurate threat assessment and rapid response. This technology allows security forces to maintain situational awareness and effectively neutralize aerial threats, regardless of lighting conditions or atmospheric interference.

Aerospace and Defense Mission-Critical Integration

For aerospace and defense platforms, reliability and performance under extreme conditions are non-negotiable. High-speed thermal imaging cameras are integrated into a variety of mission-critical systems, including intelligence, surveillance, and reconnaissance (ISR) payloads, target acquisition systems, and advanced navigation platforms. Their ability to operate across wide temperature ranges and withstand harsh environmental factors like vibration and shock makes them suitable for integration into aircraft, ground vehicles, and naval vessels. The detailed thermal data provided aids in threat identification, reconnaissance, and operational decision-making, directly contributing to mission success and personnel safety.

Industrial OEM Platform Differentiation

Original Equipment Manufacturers (OEMs) are increasingly incorporating advanced thermal imaging into their product lines to gain a competitive edge. By embedding high-speed thermal cameras, OEMs can offer enhanced functionality and performance that sets their platforms apart. This includes applications such as advanced diagnostics for industrial machinery, non-contact temperature monitoring in complex manufacturing processes, and enhanced safety features in heavy equipment. The integration of sophisticated thermal capabilities allows OEMs to deliver more intelligent, reliable, and feature-rich products to their customers, opening new market opportunities and strengthening their brand reputation.

To explore how our advanced thermal imaging solutions can benefit your demanding applications, please visit https://www.lightpath.com/contact.

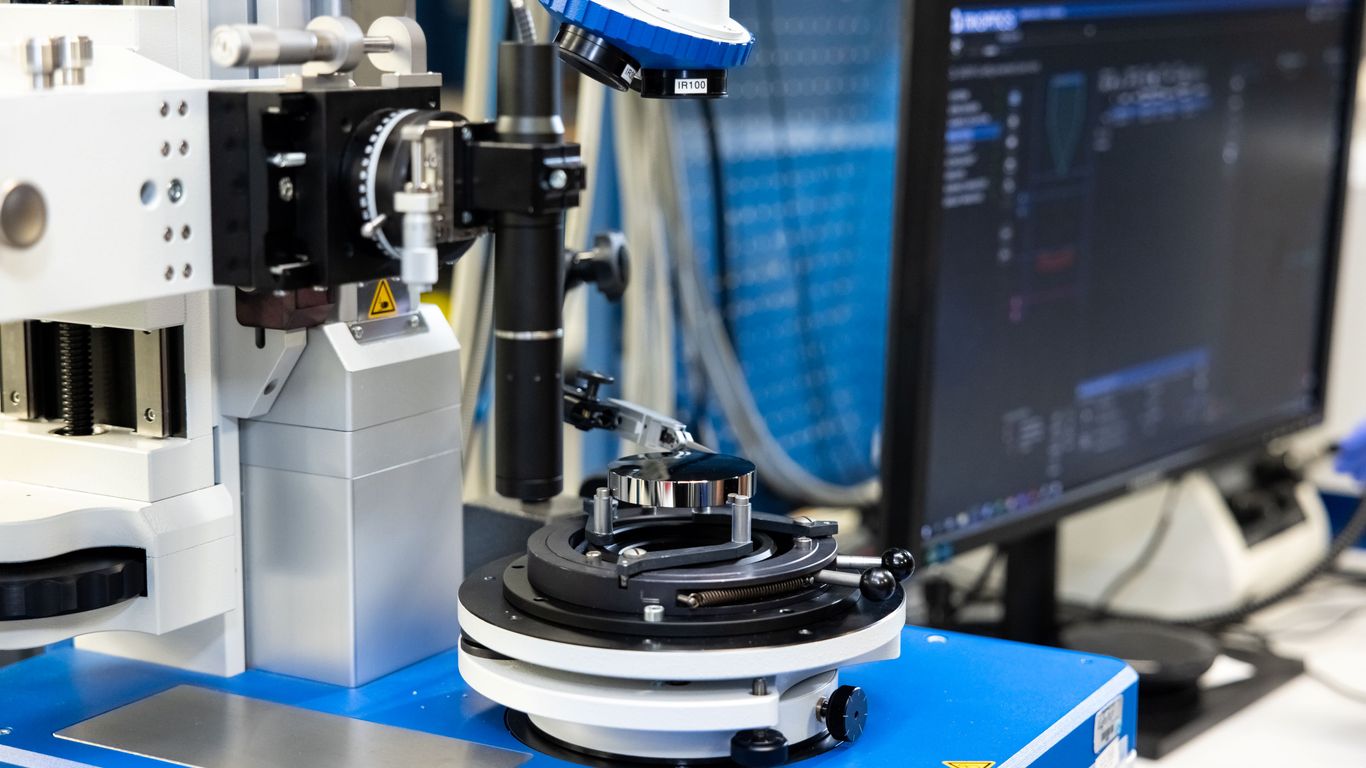

Core Technologies Driving Thermal Imaging Performance

The effectiveness of advanced thermal imaging cameras hinges on a few key technological components working in concert. These aren't just off-the-shelf parts; they are carefully engineered elements that allow these cameras to see heat signatures with remarkable detail and accuracy.

Microbolometer Arrays for Subtle Temperature Detection

At the heart of most modern thermal cameras is the microbolometer array. Think of it as a grid of tiny sensors, each one designed to detect infrared radiation – essentially, heat. When infrared energy hits a microbolometer, it causes a tiny change in its electrical resistance. The camera then measures these changes across the entire array. The more sensitive the microbolometer, the smaller the temperature difference it can detect. This sensitivity is often measured by Noise Equivalent Temperature Difference (NETD), with lower numbers indicating better performance. A low NETD means the camera can pick up on very subtle temperature variations, which is critical for tasks like spotting a small defect in a manufactured part or identifying a faint heat signature in a surveillance scenario.

Sophisticated Image Processing for Enhanced Data

Raw data from the microbolometer array is just a collection of electrical signals. To make sense of it, sophisticated image processing algorithms are essential. These algorithms take the raw data and turn it into the detailed thermal images we see. They perform several functions:

-

Noise Reduction: Algorithms work to filter out random electronic noise that can obscure fine details, improving image clarity.

-

Temperature Calibration: They translate the sensor readings into accurate temperature values, allowing for quantitative analysis.

-

Image Enhancement: Techniques like contrast adjustment and detail sharpening make thermal patterns more visible and easier to interpret.

-

Artifact Correction: Processing corrects for any distortions or inconsistencies introduced by the sensor or optics.

These processing steps are vital for transforming a raw heat map into a usable, informative image that can be relied upon for critical decisions.

Simultaneous Thermal and Visible Light Capture

Many advanced applications benefit greatly from seeing both the heat signature and the physical object at the same time. This is where the ability to capture thermal and visible light images simultaneously becomes important. By overlaying or presenting these two types of imagery side-by-side, operators can gain a much richer understanding of a scene. For example, in security applications, seeing a heat signature in the dark is one thing, but being able to correlate that signature with a specific vehicle or person in the visible spectrum provides immediate context. In industrial settings, it helps pinpoint exactly which component is overheating on a complex piece of machinery. This dual-capture capability bridges the gap between thermal data and the physical world, making interpretation more intuitive and actionable.

If you're looking to integrate these advanced thermal imaging technologies into your systems, reach out to our experts at https://www.lightpath.com/contact.

Essential Features for Mission-Capable Thermal Systems

When selecting thermal imaging technology for integration into demanding platforms, certain features distinguish systems built for mission success from those that are not. These capabilities are not merely desirable; they are fundamental to reliable operation and effective performance in critical applications.

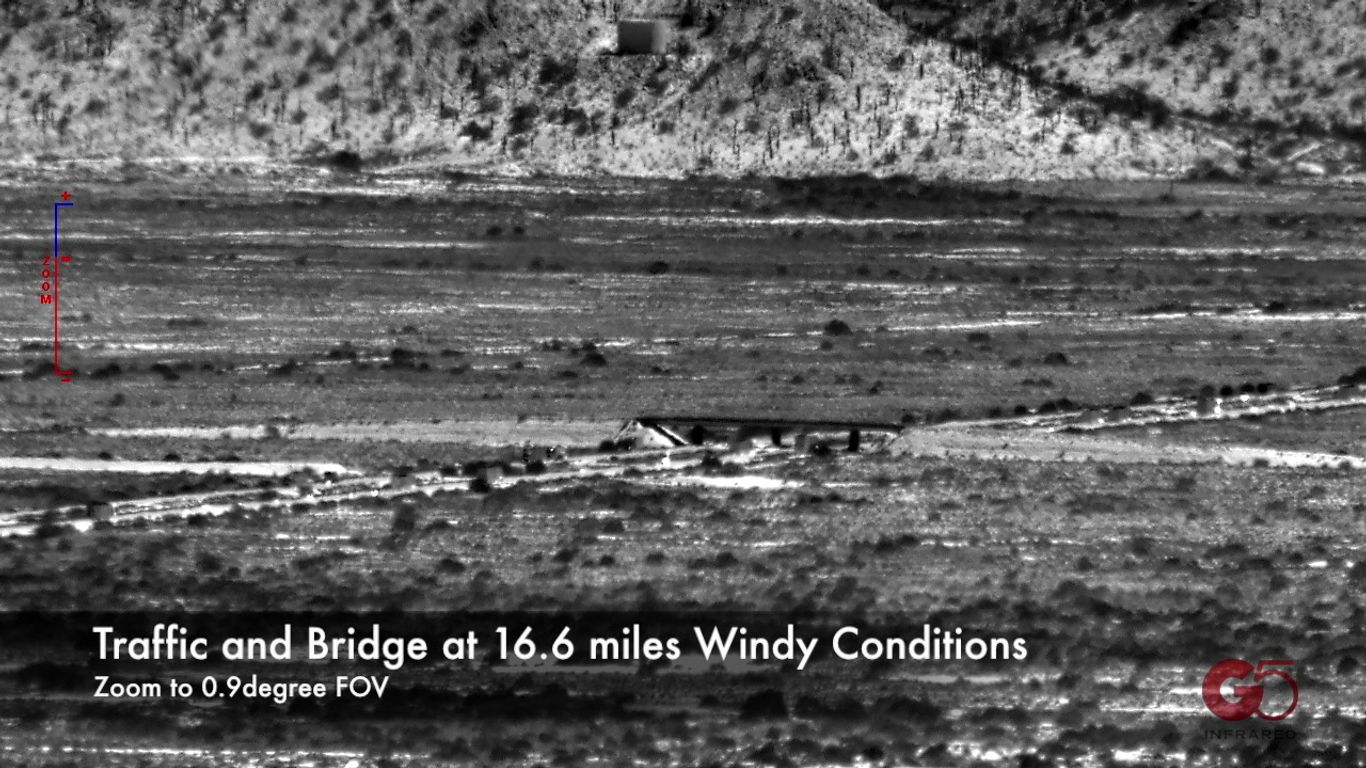

High-Resolution Thermal Imaging for Target Detection

Achieving precise target detection often hinges on the thermal camera's resolution. Professional-grade systems typically start with resolutions around 320×240 pixels, with advanced uncooled systems reaching 640×480 pixels. For specialized military and aerospace needs, even higher resolutions are available. This increased pixel density is vital for discerning subtle temperature variations across broader surveillance areas. It proves particularly important for long-range target acquisition and perimeter monitoring, where detecting small thermal signatures at maximum standoff distances directly impacts platform performance. The ability to see finer details allows operators to identify threats or anomalies with greater certainty.

Extended Temperature Range Capabilities

Many professional integration projects require temperature measurements that extend far beyond the capabilities of consumer-grade cameras. Industrial thermal camera systems commonly measure temperatures from cryogenic levels up to and exceeding 1000°C. This broad operational range is critical for applications such as monitoring industrial furnaces, evaluating electrical systems, and testing aerospace components, where extreme temperatures are a regular operational requirement. Without this extended capability, systems may fail to provide accurate data or even operate reliably in their intended environments.

Ruggedized Construction for Extreme Environments

Environments common in defense and industrial sectors demand a level of durability that standard consumer electronics simply cannot provide. Professional thermal camera systems are built with ruggedized construction, often featuring high ingress protection ratings to shield against dust, moisture, and physical impact. These systems undergo rigorous environmental testing to confirm reliable operation under extreme temperatures, high humidity, and vibration. Systems designed to meet MIL-STD specifications or appropriate industrial ratings are built to withstand conditions where equipment failure could compromise mission success or safety. This robust design ensures longevity and consistent performance when it matters most.

Transforming Industrial Processes with Thermal Insight

Modern manufacturing and industrial operations are constantly seeking ways to improve efficiency, reduce waste, and maintain product quality. High-speed thermal imaging cameras offer a powerful, non-contact method to gain critical insights into processes that were previously difficult or impossible to monitor. By visualizing heat patterns, these advanced systems allow for proactive problem-solving and optimization across a wide range of applications.

Electrical System Monitoring and Predictive Maintenance

Electrical systems are the backbone of any industrial facility, and their health directly impacts operational continuity. Over time, connections can loosen, components can degrade, and circuits can become overloaded, all of which generate excess heat. Traditional inspection methods often require shutting down equipment, leading to costly downtime. Thermal imaging cameras, however, can detect these thermal anomalies in real-time without any physical contact. This allows maintenance teams to identify potential failure points, such as hot spots in switchgear, motor control centers, or distribution panels, long before they lead to a breakdown. Implementing a predictive maintenance program that includes regular thermal inspections can prevent unexpected outages, reduce repair costs by 30-40%, and significantly improve workplace safety by mitigating fire hazards.

Rotating Machinery Assessment and Early Warning

Motors, pumps, bearings, and other rotating machinery are prone to wear and tear. Issues like bearing degradation, misalignment, or insufficient lubrication often manifest as increased friction, which in turn generates excess heat. High-speed thermal cameras can capture these subtle temperature changes, providing an early warning of developing problems. By monitoring the thermal signatures of rotating equipment, maintenance personnel can detect deviations from normal operating patterns weeks or even months before traditional methods would identify an issue. This allows for planned interventions during scheduled maintenance periods, preventing catastrophic failures, extending equipment lifespan, and avoiding costly emergency repairs and production stoppages.

Process Equipment Optimization and Quality Verification

Many industrial processes rely on precise temperature control to ensure product quality and consistency. Whether it's in chemical reactors, furnaces, kilns, or food processing lines, maintaining specific temperature ranges is critical. Thermal imaging cameras provide continuous, non-contact monitoring of these processes. They can identify uneven heating, insulation degradation, flow restrictions, or other anomalies that could compromise product specifications or lead to waste. By visualizing temperature distributions across equipment like heat exchangers, pipes, and vessels, operators can fine-tune process parameters for optimal performance and verify that products meet quality standards throughout the manufacturing cycle. This level of insight helps reduce defects, improve customer satisfaction, and maintain a competitive edge.

To explore how these advanced thermal imaging solutions can benefit your specific industrial applications, visit https://www.lightpath.com/contact.

Leveraging High Speed Thermal Imaging in Harsh Environments

Maritime Security and Coastal Monitoring

When operations extend to the sea, standard thermal cameras often struggle. Saltwater is corrosive, and constant motion from waves can shake sensitive equipment. High-speed thermal imaging cameras, however, are built to handle these conditions. They can see through fog and sea spray, which often blind regular cameras. This makes them perfect for watching ports and coastlines 24/7. They help detect boats that shouldn't be there, monitor cargo, and keep a wide area secure, even when it's dark or visibility is poor. Rugged designs mean these cameras can keep working for years in salty air that would quickly damage less robust gear. For coastal border patrols, these cameras are invaluable for spotting small vessels or people trying to cross unnoticed, especially when fog rolls in.

Extreme Temperature Operations and Reliability

Extreme temperatures are another big challenge. Most cameras are only rated for a limited range, maybe from -20°C to 50°C. But what about Arctic conditions or the heat near industrial furnaces? High-speed thermal cameras are engineered to work reliably in much wider temperature swings. Think from below -40°C in the Arctic to well over 1500°C in industrial settings. This kind of reliability is not just about surviving; it's about providing consistent, accurate data when it matters most. Without this, operations in very cold or very hot places would be much riskier and less efficient.

Gas Leak Detection and Environmental Monitoring

Harsh environments aren't just about weather; they can also involve hazardous materials. High-speed thermal imaging is a game-changer for detecting gas leaks. Certain gases are invisible to the naked eye and even to regular cameras, but they absorb or emit infrared radiation in specific ways. Specialized thermal cameras can visualize these gases, showing exactly where leaks are occurring in pipelines, industrial plants, or offshore platforms. This allows for quick action to prevent environmental damage, ensure safety, and avoid costly shutdowns. The speed of these cameras is important here too, as it allows for monitoring large areas or fast-moving leaks effectively. For environmental monitoring, they can also help track pollution plumes or assess thermal changes in sensitive ecosystems without direct contact. If you need thermal imaging solutions designed for these demanding situations, consider reaching out to our experts. Visit https://www.lightpath.com/contact to discuss your project.

Integrating AI for Real-Time Thermal Data Processing

EdgeIR: AI Hardware Embedded in the Camera

Artificial intelligence is rapidly changing how we interpret data, and thermal imaging is no exception. The sheer volume of information a high-speed thermal camera can capture demands sophisticated processing. This is where embedded AI hardware, like our EdgeIR system, comes into play. By integrating an AI accelerator directly into the camera's hardware and video pipeline, we're able to process data right at the source. This means less reliance on external computers and a significant reduction in the time it takes to get actionable insights. The Hailo-8 AI accelerator, for instance, offers substantial processing power, enabling real-time analysis that was previously unfeasible.

Reducing Latency with Integrated AI Accelerators

Latency, the delay between capturing data and acting on it, is a critical factor in many advanced applications. For systems like counter-unmanned aircraft operations or industrial process monitoring, even milliseconds can matter. Embedding AI accelerators directly into the thermal camera, as with EdgeIR, drastically cuts down this delay. Instead of sending raw data over networks for processing, the camera itself performs complex analysis. This localized processing is key for applications where immediate responses are necessary, such as detecting anomalies in manufacturing lines or identifying threats in security scenarios. This approach makes AI revolutionizing thermal image analysis more effective by bringing computation closer to the data.

Enhancing Edge Computing Efficiency

Edge computing is all about processing data closer to where it's generated, and integrating AI directly into thermal cameras is a prime example of this. This embedded intelligence allows for more efficient use of resources. The camera can pre-process, filter, and analyze thermal data, sending only the most relevant information downstream. This not only reduces the burden on network bandwidth but also allows for more sophisticated analysis to occur at the edge. For OEMs developing integrated systems, this means creating more powerful, self-sufficient solutions that require less external infrastructure. It's about making the camera smarter and the overall system more streamlined and responsive. If you're looking to integrate advanced thermal imaging into your platform, reaching out to our team can help tailor the right solution for your needs. Contact us today at https://www.lightpath.com/contact.

Using AI to quickly understand heat data is a game-changer. It helps us see problems and opportunities much faster. Imagine getting instant updates on how hot things are getting, so you can fix issues before they become big problems. This technology can make a huge difference in many areas. Want to learn more about how this smart tech works? Visit our website today to discover the possibilities!

Looking Ahead

So, we've talked a lot about these high-speed thermal cameras and what they can do. It's pretty clear they're not just for fancy science labs anymore. From keeping factories running smoothly to making sure our borders are secure, these cameras are showing up everywhere. They give us a way to see things we just couldn't before, spotting problems before they get big. With new tech like AI built right in, they're only going to get smarter and more useful. It really feels like we're just scratching the surface of what's possible with this kind of advanced imaging. Talk with a LightPath expert to learn more about thermal imaging solutions.

Frequently Asked Questions

What makes a thermal camera 'high-speed'?

A high-speed thermal camera can capture many images every second. This is important for watching things that move very fast, like in manufacturing or when looking for quick problems. It's like taking super-fast photos to see exactly what's happening.

How do thermal cameras help with quality control?

Thermal cameras can see heat. If something is made wrong, it might get too hot or too cold. By looking at the heat patterns, these cameras can find tiny flaws or mistakes in products, like in making computer chips, before they become big problems.

What is 'thermal noise' and why is it bad?

Thermal noise is like static or fuzziness in a thermal picture. It makes it hard to see small details. Good thermal cameras have very little noise, so the pictures are clear and sharp, letting you see even the smallest temperature changes.

Can these cameras work in tough places like outdoors or in extreme heat/cold?

Yes, many advanced thermal cameras are built tough. They can handle rough conditions, like being used outdoors in bad weather, or in very hot or very cold places. This makes them useful for things like watching borders or checking industrial machines.

What is EdgeIR and how does it help?

EdgeIR is like a mini-computer built right into the camera. It uses artificial intelligence (AI) to process the heat images very quickly, right where the camera is. This means the camera can understand what it's seeing faster, without needing to send the information somewhere else first.

Why are thermal cameras useful for checking electrical systems?

Electrical parts can get hot when they are about to fail or if there's a problem, like a loose connection. Thermal cameras can spot these hot spots from a distance without needing to touch anything. This helps prevent fires and keeps machines running smoothly by finding issues early.