Innovative Thermal Imaging Solutions for Enhanced Safety and Efficiency

Keeping things running smoothly and safely in industrial settings is a big deal. You don't want equipment breaking down unexpectedly, and you definitely don't want anyone getting hurt. That's where thermal imaging solutions come in. These tools let us see heat, which tells us a lot about what's going on with machines and systems, often before any obvious problems show up. It's like having X-ray vision for temperature, helping to spot issues early and keep everything working as it should.

Key Takeaways

-

Thermal imaging solutions help find equipment problems early, before they cause major breakdowns and cost a lot to fix.

-

These systems work without touching anything, so workers can check on equipment safely from a distance.

-

By spotting issues ahead of time, thermal imaging helps plan maintenance, which means less unexpected downtime and smoother operations.

-

Modern thermal imaging tools can track temperature changes over time, showing how issues develop gradually.

-

Using thermal imaging can lead to lower maintenance costs, longer equipment life, and better overall reliability.

Revolutionizing Predictive Maintenance with Thermal Imaging Solutions

Equipment failures can bring operations to a standstill, leading to significant financial losses and production delays. Traditional maintenance often relies on scheduled checks or waiting for something to break. The best thermal imaging solutions provide a more innovative approach, enabling us to identify problems before they escalate into significant issues. This technology enables us to monitor equipment without even touching it, detecting temperature changes that signal trouble long before a breakdown occurs.

Early Failure Detection for Cost Savings

Spotting a problem early can save a lot of money. Instead of dealing with a complete failure that might require expensive part replacements or even entire system overhauls, thermal imaging helps identify issues when they are small. Think of a slightly loose electrical connection that's starting to heat up. A thermal camera can see this hot spot, allowing maintenance teams to tighten it during a planned shutdown. This kind of proactive fix is far cheaper than dealing with a fire or a system outage. Studies show that using thermal imaging for predictive maintenance can reduce maintenance costs by 30-40% compared to simply waiting for issues to arise.

Non-Contact Monitoring for Enhanced Safety

Working around industrial equipment, especially electrical systems, can be dangerous. Thermal imaging lets technicians inspect equipment from a safe distance. There's no need to approach high-voltage panels or moving machinery. This non-contact approach significantly reduces the risk of accidents and injuries. It means maintenance can be performed without putting personnel in harm's way, which is a huge win for workplace safety.

Minimizing Production Disruptions Through Proactive Scheduling

Unplanned downtime is a major headache for any operation. Thermal imaging helps prevent this by enabling condition-based maintenance. Instead of relying on fixed schedules that might lead to unnecessary work or missed problems, maintenance is scheduled based on the actual condition of the equipment. If a thermal scan shows everything is fine, the scheduled maintenance might be postponed. If it reveals a developing issue, a repair can be planned for a convenient time, often during a regular shutdown. This approach can reduce unplanned downtime by up to 50%, ensuring production runs smoothly.

Enhancing Operational Efficiency Through Thermal Monitoring

Implementing thermal monitoring systems provides a direct path to enhancing the daily functioning of industrial operations. This technology surpasses simple equipment checks, offering a clear view into processes and asset health without interrupting workflow. The immediate benefits of non-invasive inspections are substantial, allowing for continuous oversight of critical systems. Instead of scheduling costly shutdowns for manual checks, thermal cameras can scan equipment during active production, identifying potential issues such as overheating components or uneven thermal distribution that may signal an impending problem. This real-time insight enables maintenance to be planned around production schedules, rather than the other way around.

Immediate Benefits of Non-Invasive Inspections

Thermal imaging's ability to monitor equipment remotely is a game-changer for operational efficiency. It eliminates the need to power down machinery or physically access hazardous areas. This non-contact approach means:

-

Uninterrupted Operations: Inspections can be conducted while equipment is running, thereby preventing production delays.

-

Enhanced Safety: Personnel are kept away from dangerous electrical or mechanical systems.

-

Comprehensive Coverage: Large areas or multiple assets can be scanned quickly, providing a broad overview of operational status.

Achieving Energy Cost Reductions

Beyond maintenance, thermal imaging plays a key role in identifying energy waste. Inefficient equipment, poor insulation, or air leaks can result in significant energy losses, leading to increased operational costs. Thermal cameras can pinpoint these areas by visualizing temperature differences. For example, they can reveal:

-

Heat Loss: Identifying areas where insulation is failing in pipes, tanks, or buildings.

-

Electrical Inefficiencies: Detecting overloaded circuits or loose connections that generate excess heat and consume more power.

-

Process Deviations: Spotting inconsistencies in heating or cooling processes that might be wasting energy.

By addressing these thermal anomalies, facilities can reduce their energy consumption and lower utility bills, contributing directly to the bottom line.

Improving Quality Control Metrics

In manufacturing, consistent product quality is paramount. Thermal imaging provides a powerful tool for quality control by monitoring temperature-sensitive processes. Whether it's ensuring uniform heating in an oven, checking the temperature of molten materials, or verifying the cooling rate of a product, thermal cameras offer objective, real-time data. This allows for:

-

Early Detection of Process Variations: Identifying deviations from set parameters before they affect a large batch of products.

-

Verification of Material Consistency: Confirming that materials are being processed at the correct temperatures.

-

Reduced Defect Rates: Minimizing scrap and rework by maintaining precise control over thermal processes.

By integrating thermal monitoring into quality control workflows, companies can improve product consistency, reduce waste, and boost customer satisfaction. To explore how these advanced thermal imaging solutions can optimize your operations, contact us today at https://www.lightpath.com/contact.

Key Industrial Applications for Thermal Imaging Solutions

Thermal imaging technology has become a cornerstone in modern industrial operations, offering a non-contact, visual method to assess equipment health and process performance. Its ability to detect temperature anomalies that often precede failures makes it indispensable across various sectors. By providing a clear thermal picture, these systems allow for proactive interventions, significantly reducing the risk of unexpected downtime and costly repairs.

Electrical System Integrity Monitoring

Electrical systems are a prime area where thermal imaging demonstrates its value. Loose connections, overloaded circuits, and degrading components all generate excess heat, creating "hot spots" that are easily identified by thermal cameras. This early detection is vital for preventing equipment failure, fires, and power outages. Regular inspections of switchgear, motor control centers, and distribution panels can reveal issues before they escalate. The non-contact nature of thermal monitoring is particularly beneficial here, allowing for the inspection of energized systems without compromising safety or requiring shutdowns. This capability is crucial for maintaining the reliability of power infrastructure and industrial electrical networks.

Rotating Machinery Health Assessment

Industrial facilities rely heavily on rotating equipment like motors, pumps, and compressors. These machines generate specific thermal patterns during normal operation. Deviations from these patterns, such as increased heat in bearings or motor windings, can indicate developing problems like wear, misalignment, or lubrication issues. Thermal imaging can detect these temperature increases weeks or even months before traditional methods, such as vibration analysis, would pick them up. This allows maintenance teams to schedule interventions during planned downtime, averting catastrophic failures and extending the lifespan of critical assets. For example, monitoring bearing temperatures in pumps can prevent costly downtime in continuous process operations.

Process Equipment Optimization and Control

Beyond electrical and mechanical systems, thermal imaging offers significant advantages in monitoring and optimizing various industrial processes. It can be used to assess the performance of heat exchangers, identify insulation degradation on pipes and vessels, and detect flow restrictions or blockages. In manufacturing, thermal cameras can monitor the temperature of products during production, such as in ovens or cooling lines, to ensure quality control and consistency. This real-time insight into process temperatures helps in fine-tuning operations, reducing waste, and improving overall efficiency. For instance, monitoring the thermal uniformity of a furnace can optimize its energy consumption and output.

Advanced Capabilities of Modern Thermal Imaging

Modern thermal imaging systems go far beyond simple temperature readings. They incorporate sophisticated features that make them incredibly useful for keeping industrial operations running smoothly and safely. These systems are designed to work in tough conditions and provide detailed information that helps prevent problems before they start.

Real-Time Trend Analysis for Developing Issues

One of the most powerful aspects of current thermal imagers is their ability to track temperature changes over time. Instead of just getting a snapshot, these devices can continuously monitor equipment and log temperature data. This allows maintenance teams to see gradual increases in temperature, which often signal developing issues like increased friction in a bearing or a connection that's starting to fail. Spotting these trends early means you can schedule maintenance during planned downtime, avoiding costly emergency repairs and unexpected shutdowns. It's like having an early warning system for your machinery.

-

Baseline Establishment: Recording normal operating temperatures helps identify deviations.

-

Gradual Degradation Detection: Tracking slow temperature rises pinpoints components nearing failure.

-

Predictive Scheduling: Data allows for maintenance to be planned when it's least disruptive.

Integration with Maintenance Management Systems

Today's thermal imaging solutions are built to work with your existing systems. They can connect with Computerized Maintenance Management Systems (CMMS) or other asset management software. This integration means that the thermal data collected isn't just stored away; it becomes part of a larger picture of equipment health. When a thermal anomaly is detected, it can automatically generate a work order or alert the relevant personnel within the management system. This streamlines the entire maintenance process, from detection to resolution, and provides a complete history of equipment condition.

Operating Reliably in Extreme Environments

Industrial settings are often harsh. High temperatures, extreme cold, dust, moisture, and vibration can challenge even the most robust equipment. Modern thermal imagers are engineered to withstand these conditions. They are built with rugged casings, often meeting military-grade standards, to protect against physical impact and environmental factors. Specialized cameras can operate in temperatures ranging from well below freezing to hundreds of degrees Celsius, making them suitable for a wide array of demanding applications. This reliability in tough environments means you can trust the data you get, no matter where it's collected. For more information on how these advanced solutions can benefit your operations, please visit https://www.lightpath.com/contact.

Driving Competitive Advantage with Thermal Imaging

Implementing advanced thermal imaging solutions provides a significant edge in today's competitive industrial landscape. By shifting from reactive repairs to proactive monitoring, organizations can substantially reduce operational costs and extend the lifespan of their critical assets. This technological adoption is not merely an upgrade; it's a strategic move that redefines maintenance practices and boosts overall efficiency.

Reduced Maintenance Costs and Equipment Lifespan Extension

One of the most immediate impacts of adopting thermal imaging is the dramatic reduction in maintenance expenditures. Traditional maintenance often involves waiting for equipment to fail, leading to costly emergency repairs, extensive downtime, and premature replacement. Thermal imaging, however, allows for the detection of developing issues, such as overheating electrical connections or failing bearings, weeks or even months before they become critical failures. This early detection means maintenance can be scheduled during planned downtime, utilizing less expensive repair parts and labor. Studies indicate that such proactive approaches can lead to maintenance cost savings of 30-40% over reactive methods. Furthermore, by addressing problems before they escalate, the operational life of equipment is significantly extended, delaying the need for capital-intensive replacements.

Optimized Equipment Reliability and Performance

Beyond cost savings, thermal imaging directly contributes to improved equipment reliability and performance. When equipment operates at optimal temperatures, it functions more efficiently and is less prone to unexpected breakdowns. Thermal monitoring provides a clear, visual representation of equipment health, enabling maintenance teams to identify and rectify anomalies that could otherwise lead to performance degradation. This continuous insight allows for condition-based maintenance, ensuring that assets are only serviced when necessary, based on their actual condition rather than arbitrary schedules. This leads to more consistent production output and higher quality products, as process deviations are identified and corrected swiftly. The global thermal imaging market, valued at USD 4.12 billion in 2024 and projected to reach USD 6.7 billion by 2032, underscores the growing recognition of these benefits. This market growth reflects a fundamental shift towards data-driven, proactive asset management.

Transforming Traditional Maintenance Approaches

Thermal imaging represents a paradigm shift in how industries approach maintenance. It moves away from guesswork and time-based schedules towards precise, data-driven insights. The benefits are multifaceted:

-

Early Failure Detection: Identify potential issues like hot spots in electrical panels or worn bearings in machinery long before they cause a breakdown.

-

Enhanced Safety: Non-contact monitoring allows technicians to assess equipment from a safe distance, minimizing exposure to hazardous environments.

-

Minimized Downtime: Proactive scheduling of maintenance based on thermal data prevents unexpected shutdowns, keeping production lines running smoothly.

-

Extended Asset Life: Timely interventions based on thermal readings prevent catastrophic failures, significantly prolonging equipment operational life.

By integrating these capabilities, companies can transform their maintenance departments from cost centers into strategic assets that drive efficiency and competitive advantage.

Expanding Horizons: Emerging Thermal Imaging Applications

Gas Leak Detection and Environmental Surveillance

Thermal imaging is stepping beyond traditional industrial monitoring to become a vital tool for environmental protection and safety. Specialized infrared cameras, particularly those operating in the Long-Wave Infrared (LWIR) spectrum, can visualize gases that are invisible to the human eye. This capability is transformative for industries like oil and gas, chemical processing, and manufacturing, where undetected gas leaks can pose significant safety risks and environmental hazards. By providing a visual representation of gas plumes, these systems allow for immediate identification and localization of leaks, enabling swift corrective action. This proactive approach not only prevents potential accidents and environmental damage but also helps facilities comply with increasingly stringent environmental regulations. Continuous monitoring with thermal imagers can cover vast areas, offering a level of surveillance that manual inspections simply cannot match.

Fire Detection and Prevention Systems

Early detection is paramount when it comes to fire safety. Thermal imaging offers a unique advantage by detecting heat signatures that often precede visible flames or smoke. This allows for the identification of potential fire hazards in their nascent stages, even in challenging environments where conventional smoke detectors might be less effective. For instance, in large warehouses, industrial plants, or areas with high electrical loads, thermal cameras can continuously scan for overheating components or smoldering materials. This early warning capability enables a faster response, potentially preventing small incidents from escalating into major fires. The ability of thermal cameras to operate in complete darkness or through smoke further enhances their utility in fire detection and prevention scenarios.

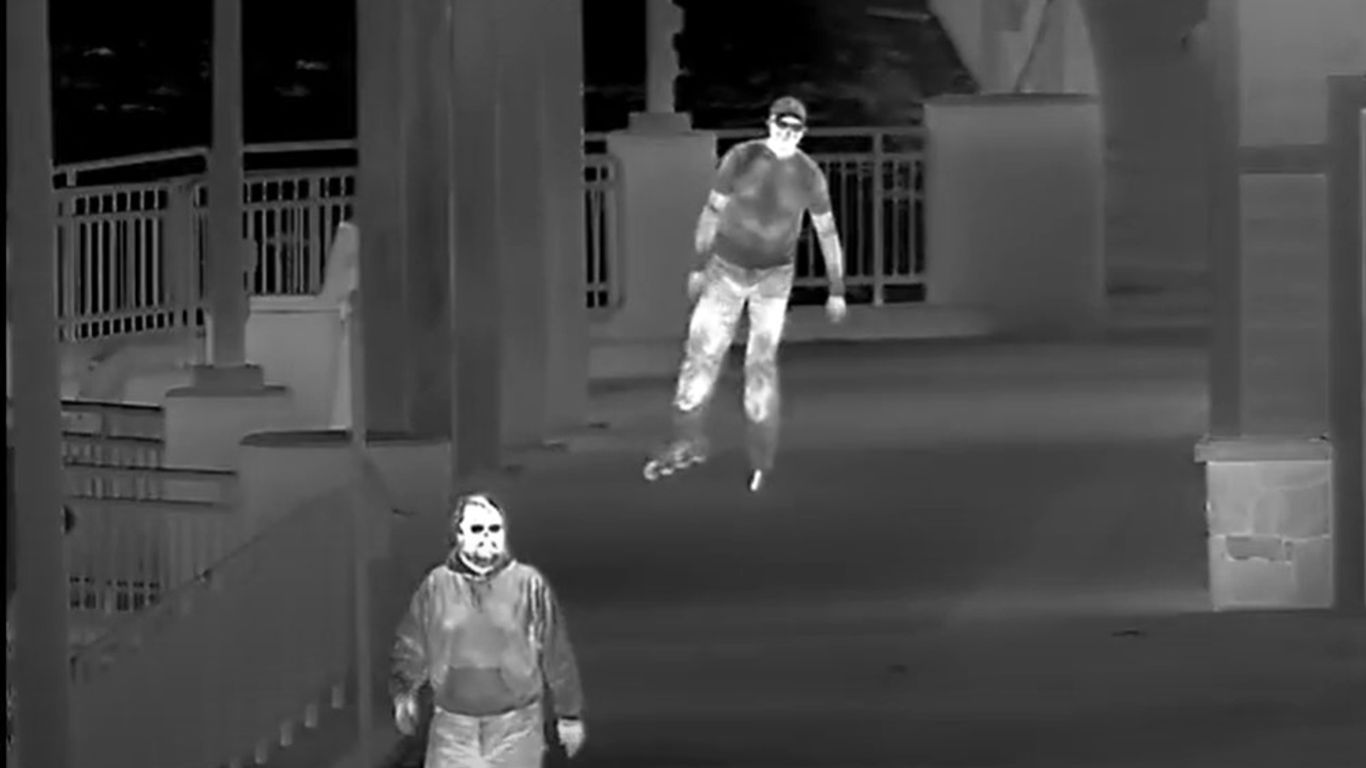

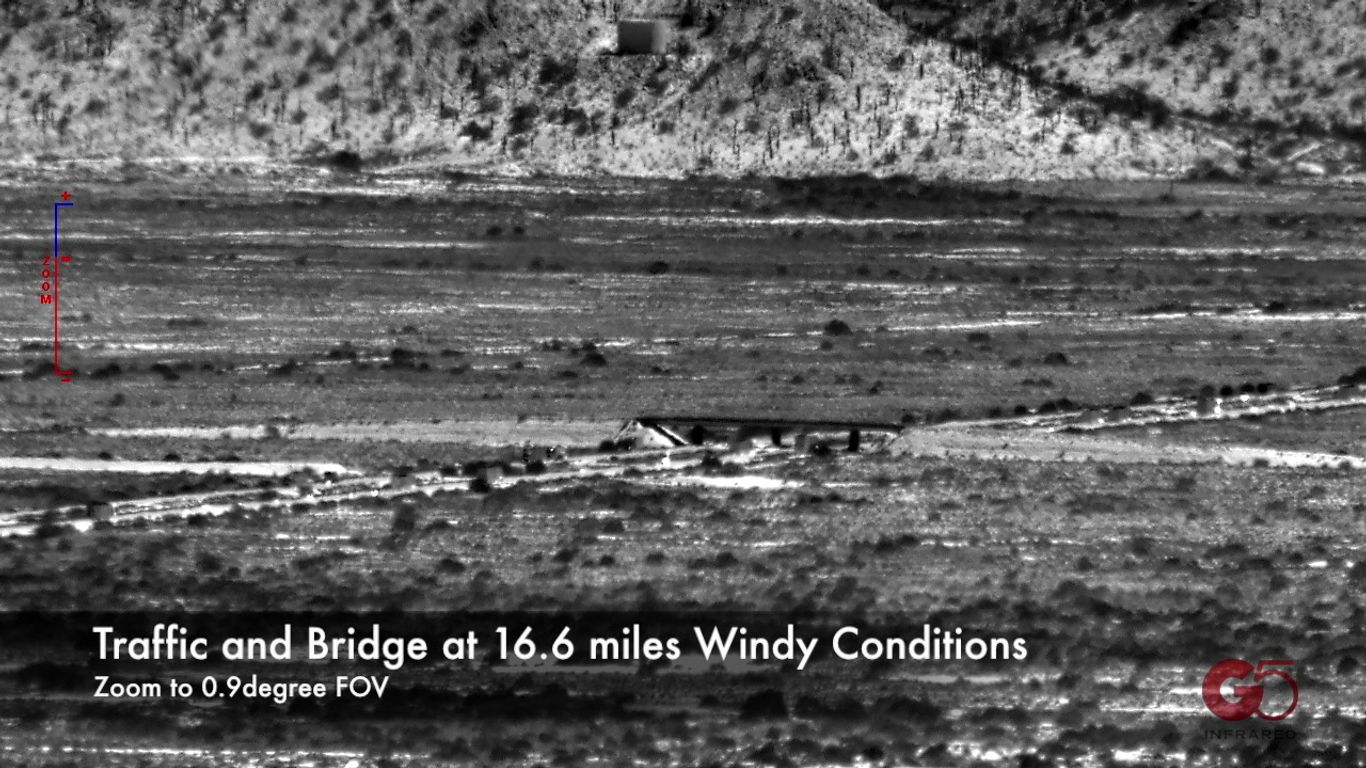

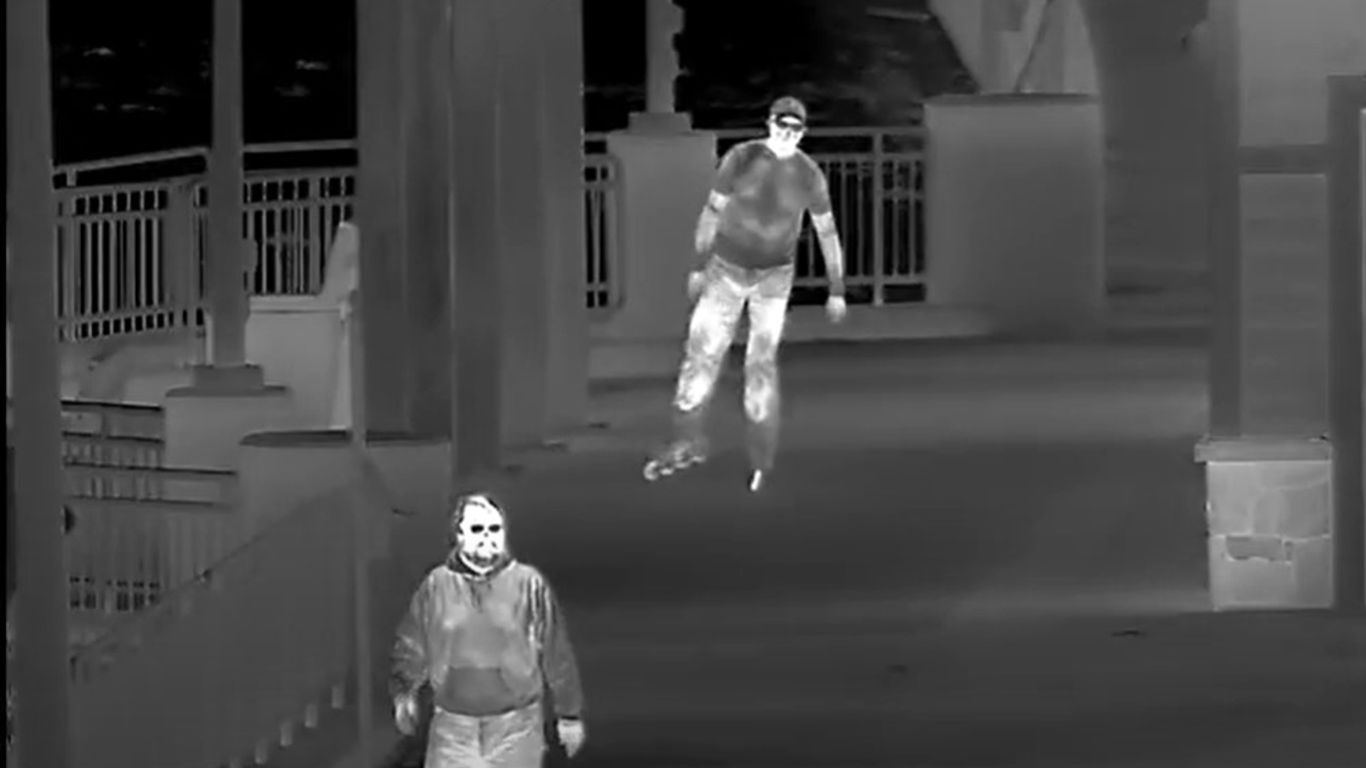

Maritime Security and Coastal Monitoring

The vastness and often challenging conditions of maritime environments demand robust surveillance solutions. Thermal imaging excels in this domain, providing clear imagery regardless of lighting conditions or weather phenomena like fog and sea spray that can obscure visible-light cameras. This makes it an indispensable tool for port security, coastal surveillance, and border patrol. Fixed installations can monitor large waterfront areas for unauthorized vessel approaches, while mobile platforms, including drones and vehicles, can conduct rapid surveys of extensive coastlines and waterways. The ability to detect heat signatures from people or vessels at significant distances contributes to enhanced situational awareness and security, helping to deter illegal activities and ensure the safety of critical infrastructure.

For more information on how advanced thermal imaging can address your specific needs, please contact us at https://www.lightpath.com/contact.

Thermal imaging is opening up new possibilities in many fields. From keeping our homes safe to helping doctors see inside us, these cameras are becoming super useful. Want to learn more about how these amazing tools are changing the world?

Looking Ahead

So, we've talked a lot about how thermal imaging is changing things, right? It's not just some fancy gadget anymore. It's actually helping businesses save money by catching problems early, making workplaces safer, and keeping production lines running smoothly. Think about it – spotting a tiny issue before it becomes a huge, expensive breakdown. That's the power here. The market's growing fast, and it's clear that companies are realizing this isn't just a nice-to-have; it's becoming a standard tool for staying competitive and efficient. To explore how advanced thermal imaging can benefit your operations, consider reaching out to our experts at https://www.lightpath.com/contact.

Frequently Asked Questions

What is thermal imaging and how does it help keep things safe?

Thermal imaging uses special cameras to see heat that objects give off. Imagine it like seeing in the dark, but instead of light, you see heat! This helps keep things safe because it can spot problems before they get bad. For example, it can find electrical parts that are getting too hot, which could start a fire. It can also see if machines are overheating, which might mean they are about to break. Because you can see these heat problems from a distance, workers don't have to get too close to dangerous equipment.

How does thermal imaging make factories run better?

Thermal imaging helps factories run better in a few ways. It lets people check machines without stopping them, which means less lost work time. It can also find places where heat is escaping, like poorly insulated pipes or walls, which helps save energy and money. By spotting problems early, factories can fix things before they cause a big shutdown, keeping production running smoothly and making sure the products made are good quality.

What are some common places where thermal imaging is used in factories?

Thermal imaging is used in many important areas. It's great for checking electrical systems, like panels and wires, to find hot spots that could cause failures. It's also used for machines that spin, like motors and pumps, to see if parts like bearings are getting too hot, which means they might be wearing out. Plus, it helps keep an eye on equipment used in making things, like ovens or furnaces, to make sure they are working at the right temperature.

Can thermal cameras work in really tough conditions?

Yes, modern thermal cameras are built tough! They can work in very cold places, like in the Arctic, or in really hot places, like near a furnace. They are also designed to handle dusty, wet, or even smoky environments where regular cameras might not work well. This means they can be used in almost any industrial setting to keep monitoring things.

How does using thermal imaging give a company an edge over others?

Companies that use thermal imaging get ahead by saving money and making their operations more reliable. They spend less on fixing machines because they catch problems early. Their machines last longer, and they have fewer unexpected shutdowns, which keeps customers happy. It's like having a superpower to see the future of your equipment, allowing you to plan maintenance smartly instead of just reacting to breakdowns.

Are there new ways thermal imaging is being used that are not about machines?

Absolutely! Thermal imaging is expanding beyond just checking machines. It can be used to find leaks of invisible gases, which is important for safety and the environment. It's also used in fire detection systems to spot fires early, even before smoke is visible. Some systems use it for security, like watching coastlines or ports to see boats or people, even at night or in bad weather.