Unlocking New Possibilities with LWIR Thermal Camera Technology

You're exploring how LWIR thermal camera technology can unlock new possibilities. Maybe you're an engineer working on a new defense system, or perhaps you're managing an industrial monitoring project. Regardless of your role, understanding this technology is crucial. LWIR thermal camera can give your project the performance and reliability it needs to succeed. This guide will break down what matters for your work.

Key Takeaways

-

LWIR thermal cameras are great for detecting heat signatures, even in total darkness or poor visibility. You don't need any extra lights for them to work.

-

These cameras can see through objects like smoke, fog, and dust relatively well, which is a significant help in challenging environments such as battlefields or industrial sites.

-

Many LWIR cameras don't need special cooling systems. This makes them smaller, uses less power, and is easier to maintain, which is good for drones or vehicles.

-

The market for thermal cameras is growing, and LWIR technology plays a significant role in this growth. Advancements are making them better and more widely used in defense and industry.

-

When integrating an LWIR thermal camera into a system, collaborating with manufacturers that offer support can significantly expedite the process and reduce the risk associated with building everything in-house.

Understanding Long-Wave Infrared (LWIR) Technology

When you're researching thermal imaging, you'll encounter numerous technical terms. LWIR, or Long-Wave Infrared, is one you'll see often. It's not just another acronym; it's a specific part of the electromagnetic spectrum that thermal cameras use to see heat. Understanding this aspect is crucial to understanding what these cameras can do for your systems.

Defining the LWIR Spectrum and Its Significance

The LWIR spectrum covers wavelengths roughly between 8 and 14 micrometers. Why is this range important? Because objects at typical environmental temperatures – think people, buildings, or machinery operating normally – emit most of their thermal radiation within this band. This is a significant advantage. It means LWIR cameras can detect heat signatures from these objects without needing any external light source. Whether it's pitch black outside or a room with no lights on, an LWIR camera can still see what's there based on its heat.

Core Principles of LWIR Thermal Imaging

LWIR thermal cameras work by detecting the infrared radiation that objects naturally emit. This radiation is invisible to the human eye. The cameras utilize specialized sensors, often microbolometers, which are made from materials such as vanadium oxide or amorphous silicon. When infrared radiation hits these sensors, it changes their electrical resistance.

Sophisticated electronics then process these changes to create a thermal image, where different colors or shades represent different temperatures. A major benefit of many LWIR systems is that they use uncooled detectors. This means they operate at room temperature, which simplifies the system, reduces power needs, and lowers costs compared to cooled systems.

LWIR vs. MWIR: A Comparative Overview

When selecting a thermal imaging technology, you'll often compare LWIR with MWIR (Mid-Wave Infrared). MWIR operates in a shorter wavelength range (typically 3.6 to 4.9 micrometers) and is better suited for detecting objects that are significantly hotter than their surroundings, like engines or exhaust systems. LWIR, on the other hand, is optimized for detecting objects at ambient temperatures.

Here's a quick look at how they compare:

|

Feature |

LWIR (Long-Wave Infrared) |

MWIR (Mid-Wave Infrared) |

|---|---|---|

|

Wavelength Range |

8-14 micrometers |

3.6-4.9 micrometers |

|

Best For |

Ambient temperature objects (people, buildings, equipment) |

High-temperature objects (engines, furnaces) |

|

Operation |

Uncooled systems common, simpler, lower cost |

Often requires cooling, more complex, higher cost |

|

Atmospheric Penetration |

Good through smoke, fog, dust |

Can be affected by water vapor, better in very dry air |

For most applications involving the detection of people, vehicles, or equipment at normal operating temperatures, LWIR provides the necessary performance with greater simplicity and cost-effectiveness. If your primary need is to detect extremely hot targets or achieve maximum range in specific atmospheric conditions, MWIR might be a better fit. Understanding these differences helps you select the most suitable technology for your specific system requirements.

Key Advantages of LWIR Thermal Cameras

When developing systems that require reliable visual data in challenging conditions, Long-Wave Infrared (LWIR) thermal cameras offer a compelling set of benefits. These cameras operate by detecting the thermal radiation naturally emitted by objects, rather than relying on visible light. This fundamental difference allows for unique capabilities that are not possible with conventional imaging.

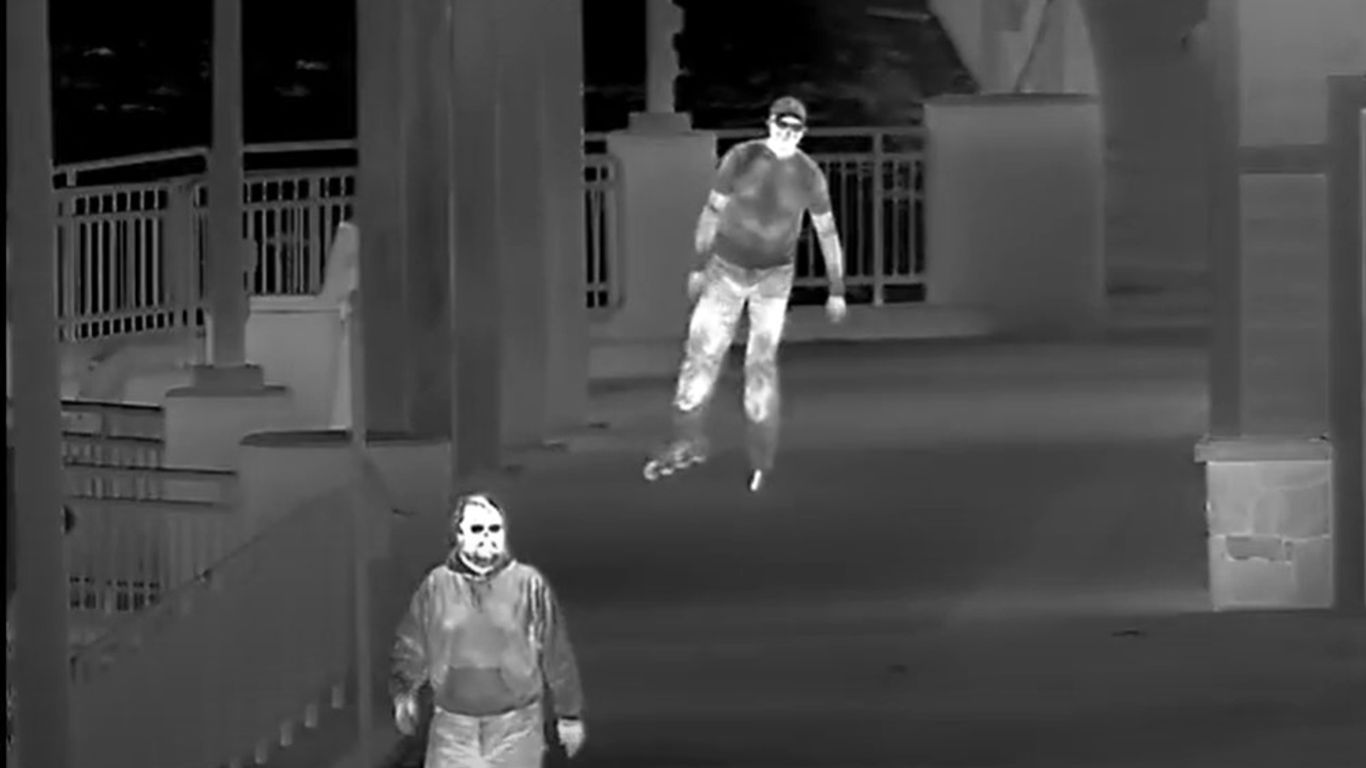

Operation in Complete Darkness and Obscuring Conditions

One of the most significant advantages of LWIR technology is its ability to operate in environments where visible light cameras are ineffective. Since LWIR cameras detect heat signatures, they provide clear imagery regardless of ambient lighting conditions. This means your system can operate effectively in complete darkness, through dense fog, smoke, or dust.

For applications such as search and rescue, security surveillance, or industrial monitoring in hazardous environments, this capability is often critical. You gain the ability to see what would otherwise be invisible, maintaining situational awareness and operational effectiveness when it matters most. This passive detection method also means your system does not emit any signals, which is a considerable advantage for operational security in defense applications.

Uncooled Operation for System Simplicity and Reliability

Many LWIR thermal cameras utilize uncooled microbolometer detectors. This design eliminates the need for complex and power-hungry cryogenic cooling systems that are often required for other types of thermal imaging. The benefits of uncooled operation are substantial:

-

Reduced System Complexity: Eliminating coolers simplifies the overall system design.

-

Lower Power Consumption: Uncooled systems require less power, which is particularly vital for battery-operated or power-constrained platforms, such as drones.

-

Smaller Size and Lighter Weight: The absence of cooling hardware enables more compact and lightweight camera modules, facilitating integration into a wider range of devices.

-

Improved Reliability: With fewer moving parts and simpler thermal management, uncooled systems typically offer higher reliability and reduced maintenance requirements.

This simplicity translates directly into faster development cycles, lower overall system costs, and improved field performance. For many applications, the performance offered by uncooled LWIR cameras is more than sufficient, making them a practical and cost-effective choice.

Penetration of Atmospheric Obscurants

Visible light and near-infrared wavelengths are easily scattered by particles in the atmosphere, such as fog, smoke, dust, and rain. LWIR wavelengths, however, pass through these obscurants with significantly less interference. This characteristic makes LWIR cameras exceptionally well-suited for operations in challenging environmental conditions.

Consider industrial settings with airborne particulates or battlefield scenarios involving smoke screens; LWIR technology maintains a clear view where conventional cameras would be rendered useless. This ability to see through atmospheric clutter provides a distinct operational advantage, allowing for continuous monitoring and detection even when visibility is severely degraded for other imaging modalities. This is particularly important for applications like maritime operations and coastal surveillance, where sea spray and haze can impact visibility.

Applications of LWIR Thermal Cameras Across Industries

Long-wave infrared (LWIR) thermal cameras are proving indispensable across a wide array of sectors, offering unique capabilities that traditional imaging cannot match. Their ability to detect heat signatures in any lighting condition and penetrate atmospheric obscurants makes them vital tools for modern operations.

Defense and Surveillance Applications

In defense and surveillance, LWIR technology provides a critical advantage. Its capacity for operation in complete darkness means that reconnaissance, border patrol, and tactical operations can continue uninterrupted, regardless of ambient light. This passive detection method also means your platform doesn't emit any signals that could compromise its position.

LWIR systems can also see through smoke, fog, and dust, which is essential for maintaining situational awareness on the battlefield or during security operations. For instance, counter-drone systems can effectively use LWIR to detect the thermal contrast of airframes, while perimeter security benefits from the reliable detection of personnel and vehicles.

Industrial Monitoring and Predictive Maintenance

Within industrial settings, LWIR thermal cameras are transforming predictive maintenance and process monitoring. They enable the inspection of equipment without direct contact, allowing for the identification of potential failures before they occur. This is particularly useful for:

-

Electrical Systems: Detecting overheating in transformers, circuit breakers, and power distribution units.

-

Rotating Machinery: Monitoring bearings, motors, and gearboxes for abnormal temperature increases that signal wear or lubrication issues.

-

Process Control: Inspecting furnaces, kilns, and other high-temperature industrial processes to ensure optimal operation and safety.

By spotting thermal anomalies early, organizations can schedule maintenance proactively, reducing costly downtime and preventing catastrophic equipment failures. The uncooled nature of many LWIR systems also simplifies integration into existing monitoring infrastructure.

Maritime Operations and Coastal Surveillance

Maritime environments present unique challenges, including fog, sea spray, and corrosive saltwater. LWIR thermal cameras are well-suited for these conditions. They enable 24/7 surveillance of ports, coastlines, and offshore assets, detecting vessels and potential threats regardless of visibility. Specialized submersion-rated LWIR systems are employed on autonomous surface vehicles and for monitoring offshore platforms.

Their ability to penetrate light fog and haze is invaluable for coastal border security, helping to identify small craft that might otherwise go undetected. These systems are engineered for resilience, often featuring ruggedized housings and corrosion-resistant materials to withstand continuous exposure to harsh marine conditions. If you are looking for solutions that can withstand these demanding environments, consider exploring options from manufacturers who offer custom integration support.

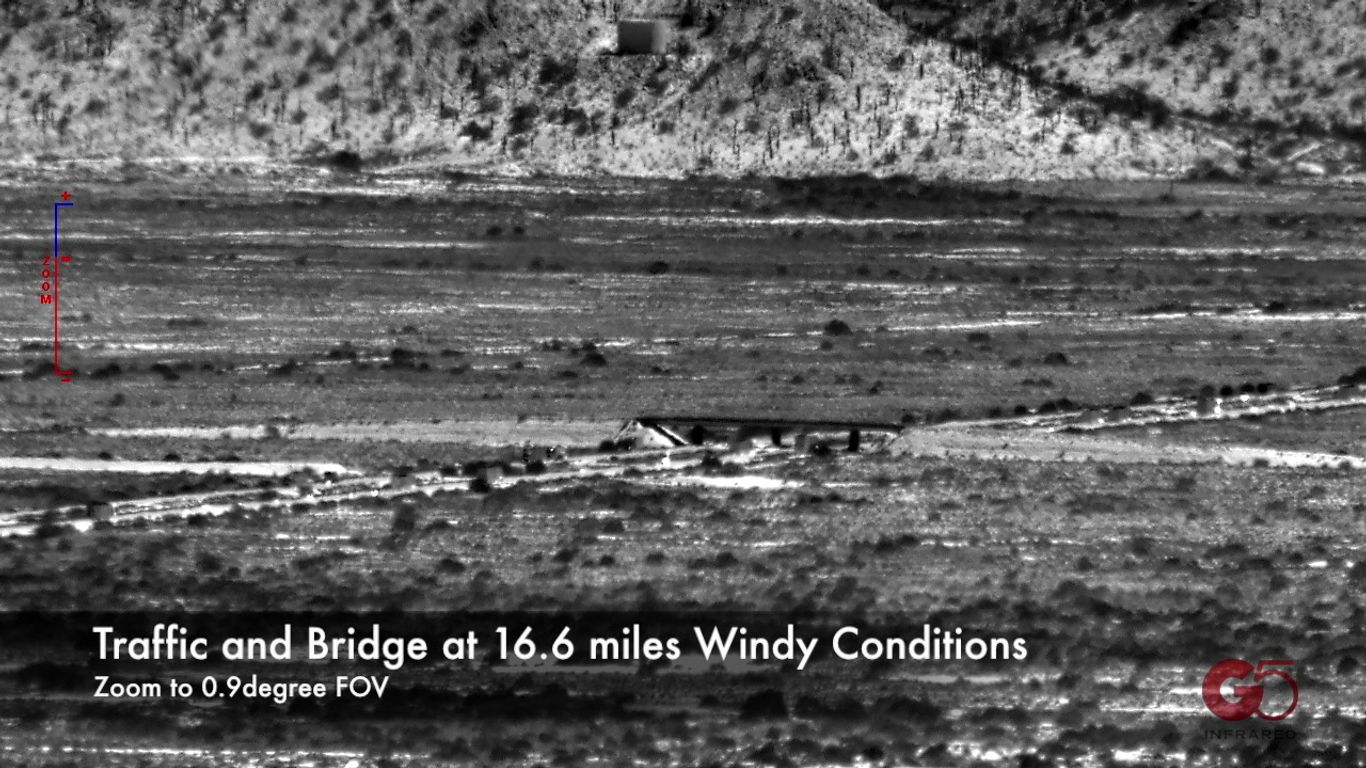

Integrating LWIR Thermal Cameras into Systems

When you're tasked with incorporating LWIR thermal cameras into your system, it's not just about picking a component off a shelf. You're looking at a process that requires careful thought about how the camera will perform within your specific application. This involves understanding potential hurdles and how to overcome them to get the best results.

Challenges and Considerations for System Builders

Integrating any new technology presents its own set of difficulties. For LWIR thermal cameras, these often revolve around the unique demands of thermal imaging and the specific environment your system will operate in. You'll need to consider:

-

Optical Performance: The lenses used with LWIR cameras are critical. Factors like focal length, aperture (f-number), and the material's transmission properties directly affect image clarity, detection range, and the ability to resolve fine details. Improperly matched optics can significantly degrade performance, even with a high-quality sensor.

-

Environmental Robustness: Will your system operate in dusty, wet, or extreme temperature conditions? The camera housing, connectors, and internal components must be able to withstand these elements without failing. This often means looking beyond standard commercial-grade equipment for solutions built for harsh environments.

-

Power and Data Management: Thermal cameras can have specific power requirements, and the data streams they produce can be substantial. You need to ensure your system's power budget can accommodate the camera and that your data handling capabilities can process the incoming information efficiently.

-

Calibration and Correction: Thermal sensors require calibration to provide accurate temperature readings. Understanding non-uniformity correction (NUC) and its application, whether through internal shutters or software, is crucial for maintaining consistent image quality. You'll need to know if this calibration is handled automatically or requires manual intervention.

Benefits of Manufacturer Integration Support

Working directly with LWIR camera manufacturers can significantly simplify this integration process. Many companies now offer more than just the camera itself; they provide support designed to help system builders succeed. This can include:

-

Customization Services: Manufacturers can often tailor camera specifications, such as lens selection or housing design, to meet your exact needs. This saves you the effort of modifying components yourself.

-

Software Development Kits (SDKs) and APIs: Access to well-documented SDKs and APIs enables seamless communication with the camera, control over its settings, and the retrieval of image data within your own software environment.

-

Technical Consultation: Experienced manufacturers can provide guidance on optical design, system architecture, and best practices for integrating their cameras, leveraging years of development experience.

-

Factory Calibration and Testing: Cameras that come factory-calibrated and tested for specific environmental conditions reduce the burden on your team and provide greater confidence in performance from day one.

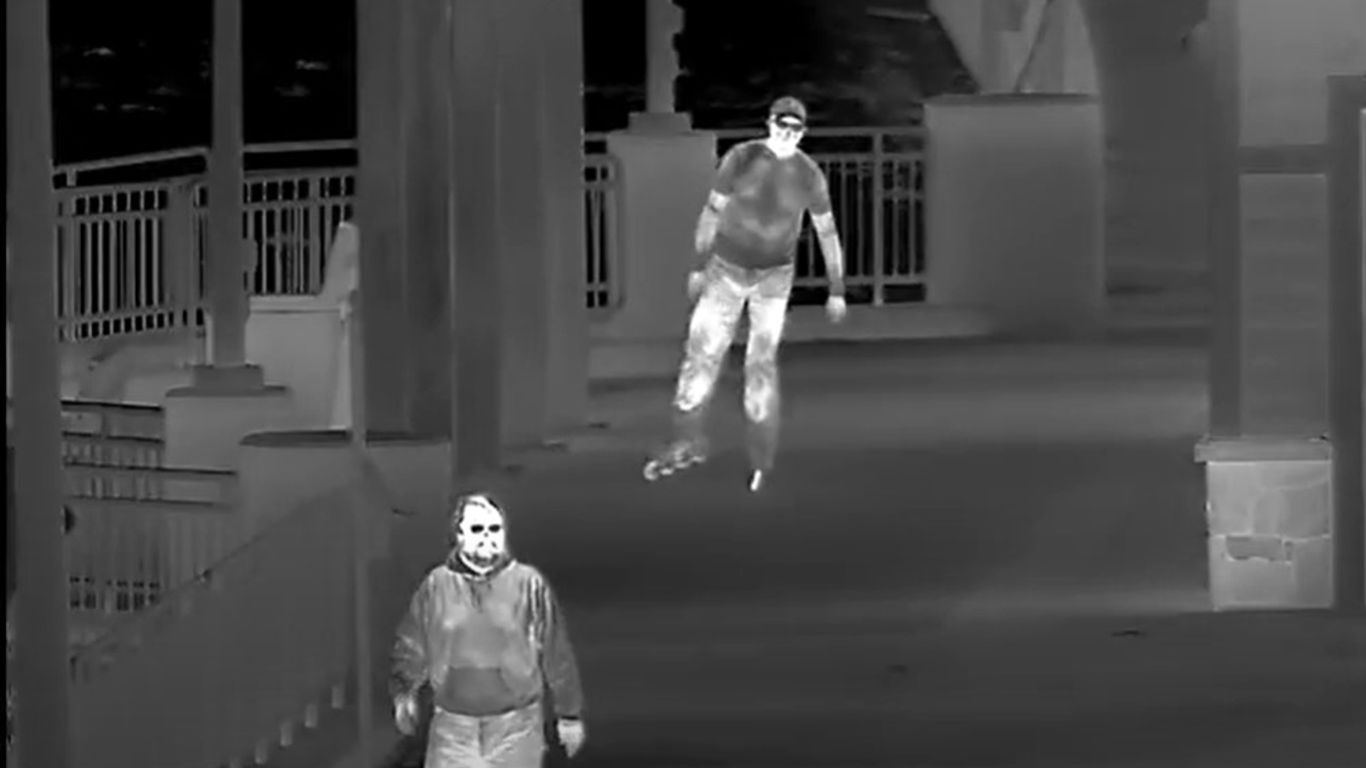

Optimizing Optical Components for Performance

The optics are a vital part of any LWIR system. Selecting the right lenses and ensuring they are properly integrated is key to achieving the desired performance. Consider these points:

-

Material Selection: Germanium is a common material for LWIR lenses due to its transparency in the long-wave infrared spectrum. However, its cost and fragility are factors. Other materials may be suitable depending on the specific wavelength range and environmental requirements.

-

Athermalization: Thermal expansion and contraction can affect the focus of a lens. Athermalized lenses are designed to maintain focus across a range of temperatures, which is critical for applications where temperature fluctuations are significant.

-

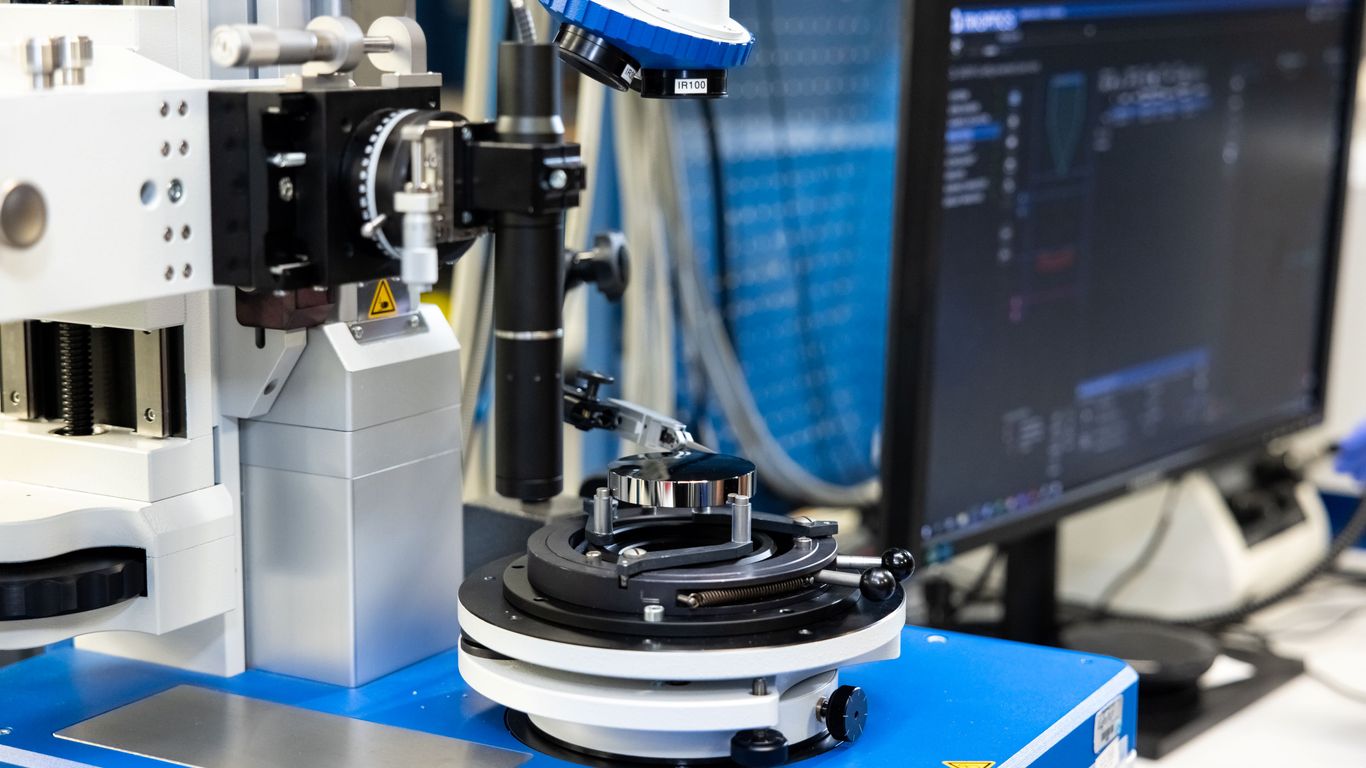

Field of View (FOV) and Resolution: The choice of lens directly impacts the FOV and the resolution you can achieve. A wider FOV captures more of the scene but may reduce detail, while a narrower FOV provides more detail but covers a smaller area. Matching the lens to your application's detection and recognition needs is paramount.

By carefully considering these integration aspects and working with knowledgeable partners, you can effectively deploy LWIR thermal cameras to meet your system's objectives. If you're looking for expert guidance on integrating LWIR thermal cameras into your next project, reach out to us at https://www.lightpath.com/contact.

Performance Characteristics of LWIR Systems

When selecting an LWIR thermal camera, understanding its performance characteristics is crucial to ensuring it meets your system's specific needs. These characteristics determine how well the camera performs in various conditions and what level of detail you can expect. It's not just about the raw specifications; it's about how those specifications translate into real-world operational capability.

Sensitivity and Detection Capabilities

Sensitivity, often measured by Noise Equivalent Temperature Difference (NETD), tells you how small a temperature difference the camera can detect. For uncooled LWIR systems, NETD values typically range from 30 to 50 millikelvins (mK). While cooled Mid-Wave Infrared (MWIR) systems might offer higher sensitivity (below 20 mK), uncooled LWIR systems provide sufficient capability for most common applications, such as detecting people, vehicles, or equipment operating near ambient temperatures.

The choice here often involves a trade-off: higher sensitivity usually means more complex and costly systems. For many applications, the sensitivity of uncooled LWIR is more than adequate, especially when paired with suitable optics. It's essential to consider the NETD in conjunction with the lens used, as the optical system has a significant impact on the final detection performance.

Operation in Extreme Temperature Environments

LWIR cameras are designed to operate across a wide range of ambient temperatures, but the camera's own internal components must also function reliably. Some systems are engineered for extreme conditions, capable of operating in environments as cold as -40°C or even lower, while others are built for higher temperatures. The thermal stability of the detector and associated electronics is critical.

When operating in extremely cold environments, the camera must maintain its calibration and performance without requiring excessive warm-up time. Conversely, in hot environments, effective thermal management within the camera housing prevents overheating and degradation of performance. The materials used in both the sensor and the optics must also be able to withstand these temperature extremes without compromising their integrity or optical properties.

Image Quality and Detail Resolution

Image quality in LWIR systems is a combination of sensor resolution, optical design, and image processing. While higher sensor resolution (e.g., 640x512 pixels versus 320x240 pixels) can provide more detail, it's not the only factor. The lens's focal length and design play a significant role in determining the instantaneous field of view (IFOV) per pixel, which directly affects the camera's detection range and ability to resolve fine details.

A well-designed optical system, even with a lower-resolution sensor, can outperform a system with a higher-resolution sensor but a less optimized lens. Factors like Modulation Transfer Function (MTF) and athermalization of the optics are also crucial for maintaining image sharpness and accuracy across different temperatures. Effective image processing algorithms can further refine the thermal data, reducing noise and improving the clarity of the final image, making it easier for you to interpret the scene.

The Evolving LWIR Thermal Camera Market

Market Growth Drivers and Projections

The market for thermal imaging cameras is experiencing significant expansion, with projections indicating a substantial increase in value over the coming years. This growth is fueled by a growing recognition of thermal imaging's utility across various sectors, moving it from a specialized tool to a more integrated component of operational infrastructure. Key drivers include advancements in infrared detector technology, which continually improve performance and reduce costs, alongside increasing demands for enhanced security and more sophisticated industrial monitoring capabilities. Organizations are increasingly investing in these systems to gain a competitive edge and improve operational efficiency.

Technological Advancements in LWIR

Recent technological progress in LWIR systems is making them more accessible and capable. A notable development is the integration of AI hardware directly into the camera, such as the EdgeIR system powered by the Hailo-8 AI accelerator. This embedded processing capability, offering up to 26 TOPS, allows for real-time data analysis directly at the edge, reducing latency and the need for external processing units.

Furthermore, advancements in detector sensitivity are enabling the detection of smaller temperature differences, which is particularly beneficial for applications such as quality control in manufacturing, where identifying subtle thermal anomalies is crucial for defect detection. These innovations are expanding the capabilities of LWIR cameras.

Strategic Partnerships for Development

Developing and integrating advanced LWIR thermal camera technology often involves strategic collaborations. System builders and original equipment manufacturers (OEMs) are finding that partnering with vertically integrated manufacturers streamlines the development process. These partnerships can provide access to a full spectrum of components, from specialized optical materials to complete camera assemblies.

An integrated approach helps reduce supply chain complexities, accelerates product development timelines, and ensures that optical components are optimized to work together as a cohesive system. Such collaborations are key to bringing innovative thermal imaging solutions to market efficiently and effectively. If your organization is looking to integrate advanced thermal imaging capabilities, consider reaching out to experts who can guide your development process at https://www.lightpath.com/contact.

The market for long-wave infrared (LWIR) thermal cameras is undergoing rapid change. New uses are emerging all the time, making these cameras more crucial than ever. Want to learn more about how these cameras work and what they can do? Visit our website to explore the latest in thermal imaging technology.

Looking Ahead

LWIR thermal camera technology is becoming an essential tool for various applications, from ensuring safety to optimizing factory operations. You've learned how it works in the dark, through fog, and how it's getting simpler to put into your own systems. When planning your next project, remember what this technology can do. It's out there, ready to help you get things done better and maybe even in ways you hadn't thought of before. It’s definitely worth considering for your next project. Talk with an LWIR camera expert at LightPath.com.

Frequently Asked Questions

What exactly is LWIR technology?

LWIR stands for Long-Wave Infrared. Think of it as a special kind of light that we can't see with our eyes, but cameras can. LWIR cameras detect the heat that objects naturally give off. This means they can see things even when it's completely dark, such as at night or inside a building with no lights on. It's like having superhero vision for heat!

How does an LWIR camera work?

Imagine every object that's warm gives off invisible heat waves. LWIR cameras are designed to 'see' these heat waves. They use special sensors that become slightly warmer when they detect these waves. Then, the camera turns that heat information into a picture you can understand, showing hot things as bright and cool things as dark, or vice versa.

Can LWIR cameras see through fog or smoke?

Yes, LWIR cameras are particularly effective at penetrating conditions such as fog, smoke, and even light rain. These things can block normal cameras, but the heat waves that LWIR cameras detect can pass through them much better. This is extremely helpful for tasks such as searching for people in smoky buildings or monitoring areas when the weather is unclear.

Do LWIR cameras need to be cooled down to work?

Most LWIR cameras don't need special cooling systems. They work fine at normal room temperatures. This makes them simpler, smaller, and less expensive to use compared to other types of thermal cameras that require very cold temperatures for operation. It also means they use less power and need less maintenance.

What's the difference between LWIR and MWIR cameras?

LWIR and MWIR both detect heat, but they examine different 'colors' or wavelengths of heat. LWIR is best suited for seeing everyday objects at normal temperatures, such as people or machines. MWIR can sometimes see further or detect smaller temperature differences, especially with very hot things, but it's often more complex and costly. For most common tasks, LWIR is the go-to choice.

Where are LWIR cameras used?

You'll find LWIR cameras in many places. They're used by the military for surveillance, by police for locating individuals in low-light conditions, and in factories to monitor if machines are overheating and might malfunction. They're also used on boats for nighttime visibility and on drones for various tasks. Essentially, wherever you need to detect heat, LWIR cameras can assist.