Advancements in Optical and Thermal Imaging for Enhanced Surveillance

If you're looking to gain a better understanding of how optical and thermal imaging are revolutionizing surveillance, you're in the right place. These technologies allow you to see things that you can't with the naked eye, especially when it's dark or visibility is poor. We'll break down what's new and what you need to know to make smart choices for your needs.

Key Takeaways

-

Choosing the right thermal camera system is vital for tactical drone missions, from general observation to countering other drones.

-

While cooled thermal systems offer top-tier long-range detection for critical tasks, uncooled cameras are better for drones needing to be small, light, and power-efficient for longer flights.

-

The quality of a thermal system relies on its optical design, how well the lens and sensor work together, and any special filters used.

-

Working with manufacturers who handle the whole production process, from materials to the final camera, means better customization, a more reliable supply chain, and overall better system performance compared to just buying off-the-shelf parts.

-

Companies that focus on specially designed thermal imaging solutions, rather than just standard cameras, gain a real edge in detection range, easier integration, and market competitiveness.

Advancements in Optical and Thermal Imaging Technology

Understanding Long-Wave Infrared (LWIR) vs. Mid-Wave Infrared (MWIR)

When you are selecting thermal imaging technology for your system, a primary decision point involves choosing between Long-Wave Infrared (LWIR) and Mid-Wave Infrared (MWIR) spectral bands. Each band offers distinct advantages that suit different operational needs and environmental conditions.

LWIR cameras typically operate in the 8-14 micrometer range, making them excellent for detecting the thermal radiation emitted by objects at ambient temperatures. They are particularly effective at penetrating atmospheric obscurants like fog, smoke, and haze, which is a significant benefit for surveillance in challenging weather.

MWIR cameras, on the other hand, operate in the 3-5 micrometer range. They are often used for detecting objects with higher temperatures or for applications where higher spatial resolution is paramount.

The choice between LWIR and MWIR impacts everything from detection performance and range to system cost and maintenance requirements. For instance, LWIR is generally preferred for general surveillance and border monitoring due to its ability to penetrate atmospheric conditions, while MWIR might be chosen for specific targeting applications that require finer detail on hotter objects.

|

Feature |

Long-Wave Infrared (LWIR) |

Mid-Wave Infrared (MWIR) |

|---|---|---|

|

Wavelength Range |

8-14 µm |

3-5 µm |

|

Primary Use Cases |

Surveillance, Border Patrol, Predictive Maintenance |

Target Identification, High-Temperature Detection |

|

Atmospheric Penetration |

Excellent (fog, smoke, haze) |

Good (less effective than LWIR) |

|

Object Temperature |

Ambient to High |

High to Very High |

The Role of High-Sensitivity Thermal Cameras

High-sensitivity thermal cameras are becoming indispensable for applications where detecting subtle temperature differences is critical. These cameras feature a low Noise Equivalent Temperature Difference (NETD), which means they can discern even minute thermal variations. This capability is vital for identifying camouflaged targets, detecting small heat leaks, or spotting early signs of equipment malfunction.

For counter-unmanned aircraft systems (C-UAS), this sensitivity allows for the precise detection and tracking of drones, even when they have similar thermal profiles to their surroundings. In industrial settings, it enables the identification of developing issues in electrical systems or machinery long before they become critical failures. The ability to see these fine details provides a significant operational advantage, ensuring that no critical information is overlooked, regardless of the environment's complexity.

Passive Detection Architecture of Thermal Imaging

Thermal imaging systems operate on a passive detection architecture, meaning they do not emit any energy themselves. Instead, they detect the infrared radiation naturally emitted by objects. This passive nature offers several advantages for surveillance and security applications. Firstly, it makes the system inherently covert; there is no energy emission that could be detected by adversaries, revealing the camera's presence or location. This is a significant benefit for tactical operations and perimeter security.

Secondly, passive detection means the system is not susceptible to countermeasures that might target active illumination sources. The camera simply 'sees' the heat signatures of objects against their background. This enables reliable detection in complete darkness, through smoke, fog, or other obscuring conditions, without requiring external light sources. This fundamental characteristic makes thermal imaging a robust and discreet surveillance tool.

Optimizing Optical and Thermal Imaging for Surveillance

When designing surveillance systems, striking the right balance between visibility and distance is crucial. It's not just about having the most powerful camera; it's about making sure it works for the specific job you need it to do. This means examining aspects such as the field of view and resolution to ensure your system is as effective as possible.

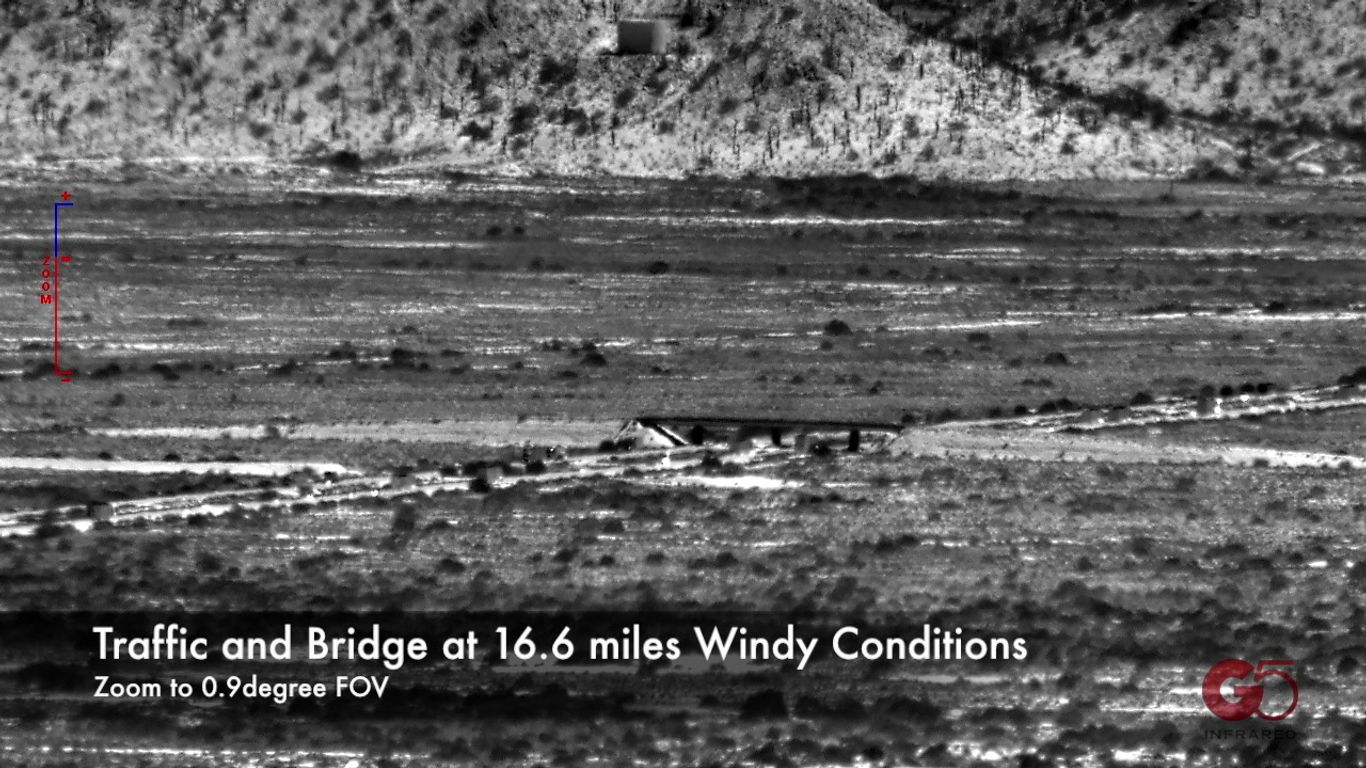

Balancing Field-of-View and Detection Range

The field-of-view (FOV) and detection range are directly related, and you often have to make a trade-off between them. A wide FOV lets you cover a larger area, which is great for general surveillance or when you need to keep an eye on a broad space. However, this wider view means that objects at a distance will appear smaller and harder to detect. On the other hand, a narrow FOV can let you see farther and identify smaller details at a distance, but it significantly limits the amount of area you can monitor at any one time.

-

Wide FOV: Ideal for situational awareness and covering large areas quickly. Consider monitoring a wide perimeter or a large, open space.

-

Narrow FOV: Better for identifying specific targets or observing distant objects. This is useful for tracking a particular vehicle or person.

-

Dual-Sensor Systems: Many advanced systems combine both wide and narrow FOV lenses, allowing operators to switch between them. This provides both broad area coverage and the ability to zoom in for detailed observation, though it adds complexity and weight.

The Impact of Resolution on Search Effectiveness

It's a common thought that higher resolution always means better search effectiveness, but that's not always the case, especially in the initial stages of detection. For instance, a thermal camera with a lower resolution but a wide field of view might be more effective at spotting potential targets over a large area than a very high-resolution camera with a narrow view. The lower-resolution camera covers more ground, increasing the chances of an initial detection. Higher resolution becomes increasingly important once a potential target has been identified, enabling positive identification and detailed analysis.

-

Initial Detection: Lower resolution with a wider FOV can be more efficient for scanning large areas and finding anomalies. A 320x240 resolution camera might be perfectly adequate for this initial sweep.

-

Identification: Higher resolution is crucial for confirming the identity of a detected object, distinguishing between similar targets, or reading details such as license plates. Resolutions of 640x480 or higher are often preferred for this phase.

-

System Design: Consider how resolution and FOV work together. A system might use a fixed wide-FOV camera for general surveillance and a separate, higher-resolution or zoom camera for detailed inspection once a target is flagged.

Multi-Sensor Integration for Enhanced Situational Awareness

To truly optimize surveillance, integrating multiple types of sensors is often the best approach. Combining thermal imaging with visible-light cameras, for example, gives you the best of both worlds. You can see in complete darkness or through obscurants with thermal imaging, and then use the visible-light camera to obtain detailed color information and context.

Adding other sensors, such as laser rangefinders, can further enhance accuracy by providing precise distance measurements to targets. This layered approach provides a more comprehensive and nuanced picture of the operational environment, enabling better decision-making and more effective responses.

-

Thermal + Visible Light: Provides 24/7 surveillance capability, allowing for detection in all lighting conditions and identification in daylight or with illumination.

-

Sensor Fusion: Advanced systems can overlay thermal and visual data, helping operators correlate heat signatures with physical objects and improving target recognition.

-

Additional Sensors: Integrating laser rangefinders, GPS, or radar can provide precise location data, distance measurements, and tracking capabilities, creating a comprehensive operational picture.

To learn more about how advanced imaging solutions can benefit your specific surveillance needs, please visit https://www.lightpath.com/contact.

Operational Considerations for Thermal Imaging Systems

When evaluating thermal imaging systems for your projects, it's not just about the raw specifications. You have to consider how these systems will function in the real world, day in and day out. This means considering a few key operational factors that can make or break a deployment.

Flight Endurance and System Weight

For any application involving aerial platforms, especially drones, the weight and power consumption of the thermal imaging system are critical. Every gram added to the payload directly impacts how long the drone can stay airborne. Lighter, more power-efficient uncooled thermal cameras are often favored for extended surveillance missions where maximizing flight time is paramount.

Cooled systems, while offering superior detection range and sensitivity, typically have a larger footprint and higher power demands, which can significantly reduce flight endurance. You need to balance the need for long-range detection with the practical limitations of your platform's flight time and payload capacity. It's a trade-off that requires careful consideration of your specific mission profile.

Environmental Resilience and Extreme Temperature Operations

Thermal cameras must function reliably across a wide range of environmental conditions. Standard commercial systems typically operate within a limited temperature range, ranging from -20°C to 50°C. However, mission-critical applications often demand performance in much harsher environments. Consider Arctic conditions, where temperatures can plummet below -40°C, or industrial settings with ambient temperatures exceeding 1500°C. Systems deployed in these extremes must be purpose-built to withstand the extreme conditions. This includes considerations like:

-

Sealed Housings: Protection against dust, sand, moisture, and corrosive elements, such as saltwater, is vital. Look for IP ratings (e.g., IP67 or IP69K) that indicate robust sealing.

-

Thermal Management: For high-temperature environments, specialized cooling systems or thermal barriers might be necessary to prevent the camera from overheating.

-

Material Durability: Components must withstand extreme cold without becoming brittle and extreme heat without degrading.

Radiometric Capability in Continuous Video

Many thermal cameras provide radiometric data, meaning they can measure and record precise temperature values for each pixel. This is incredibly useful for industrial inspections, predictive maintenance, and scientific research. However, a crucial distinction exists between radiometric still images and radiometric continuous video. Some systems offer radiometric data only in still shots, while others provide it throughout video recording.

If your application requires real-time temperature monitoring and trending over time, you must verify that the system supports full-motion radiometric video. Relying on systems that only offer radiometric stills for continuous monitoring tasks can lead to significant operational limitations and inaccurate data analysis. Always confirm this capability with your supplier before making a decision.

Applications of Optical and Thermal Imaging in Demanding Environments

When your operations extend beyond controlled settings, standard imaging equipment often struggles to perform effectively. Saltwater can corrode electronics, desert sand can infiltrate unsealed housings, and extreme cold can shut down systems not built for subzero temperatures. These aren't just theoretical issues; they are practical challenges for anyone specifying equipment for harsh environments.

Maritime Security and Coastal Monitoring

Ports and coastlines require constant oversight, regardless of weather or time of day. Fixed thermal imaging systems, designed for outdoor use, can monitor unauthorized boats approaching, track cargo handling, and survey large waterfront areas. These cameras are built to withstand years of exposure to salty air, which can quickly damage less robust equipment. For coastal border surveillance, thermal cameras mounted on towers or mobile platforms can spot small vessels and illegal crossings. Long-wave infrared (LWIR) is particularly useful in this context because it can penetrate through light fog and haze, conditions common along coastlines that often limit visibility for other sensors.

Industrial Monitoring Under Challenging Conditions

Industrial settings present a mix of heat, dust, vibrations, and chemical exposure. Thermal imaging systems used in these places must stay accurate and reliable despite these conditions. Manufacturing plants increasingly use thermal imaging for predictive maintenance. By spotting unusual temperatures in electrical systems or machinery, potential problems can be found before they cause unexpected shutdowns. For example, electrical utilities use rugged thermal cameras at substations to check transformers and connections. These cameras operate continuously outside, identifying hot spots that signal a failing connection or an overloaded part, which helps prevent power outages and costly emergency repairs.

Desert and Arid Environment Deployment

Deploying systems in deserts means dealing with extreme temperature shifts, intense sun, and constant dust and sand. Equipment must handle daytime temperatures well over 100°F (38°C) and then perform reliably when temperatures drop significantly at night. Sand and dust can ruin unsealed equipment by abrading moving parts and contaminating lenses. Military-grade thermal imaging systems for desert use typically feature sealed housings (such as IP67 ratings), filtered air systems, and robust lens covers to protect against particles. Thermal imaging in these regions supports a range of applications, from securing perimeters to vehicle surveillance.

Strategic Integration of Thermal Imaging in Platform Development

When developing new platforms, particularly in high-demand sectors such as aerospace, defense, and industrial monitoring, integrating thermal imaging capabilities necessitates careful consideration. Ensuring that the thermal system becomes a core component will provide a distinct advantage. This strategic integration can significantly differentiate your product in a competitive market.

OEM Platform Integration Best Practices

Integrating thermal imaging into an Original Equipment Manufacturer (OEM) platform involves more than just selecting a camera. It requires a methodical approach to ensure optimal performance and reliability. Consider these best practices:

-

Define Performance Requirements Early: Clearly outline the necessary detection range, field of view, resolution, and environmental operating conditions. This upfront definition prevents costly redesigns later.

-

Consider Size, Weight, and Power (SWaP): For airborne platforms, especially drones, SWaP is a critical consideration. Every gram and watt counts, impacting flight endurance and payload capacity. Select thermal cores engineered for low SWaP.

-

Plan for Environmental Robustness: Ensure the chosen thermal system can withstand the intended operating environment, including temperature extremes, vibration, dust, and moisture. Ruggedized construction and appropriate sealing (e.g., IP ratings) are vital.

-

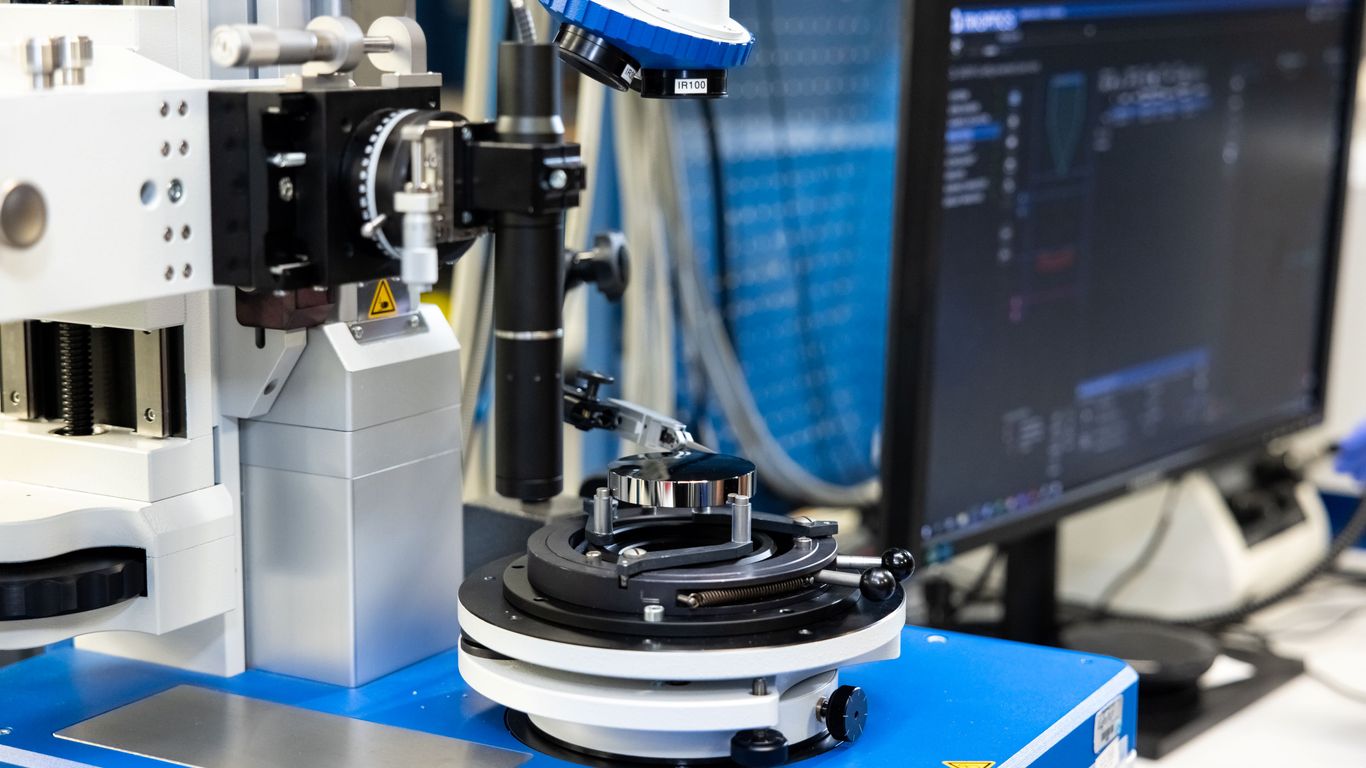

Optimize Optical Path: The quality of the optics directly impacts image clarity and detection range. Look for systems with advanced optical designs, such as those featuring cold-shield efficiency, to minimize image artifacts and ensure consistent performance across all zoom levels.

Supply Chain Security and Manufacturing Provenance

For mission-critical applications, the origin and reliability of your thermal imaging components are paramount. A secure and transparent supply chain mitigates risks and ensures the long-term viability of the program.

-

Traceability and Compliance: Verify that components are traceable and meet regulatory requirements, including those applicable to defense applications. This includes understanding the origin of key materials, such as germanium.

-

Manufacturing Continuity: Partner with manufacturers who have robust production capabilities and can guarantee long-term availability of components. This is especially important for platforms with extended lifecycles.

-

Domestic Manufacturing: For certain programs, domestic manufacturing or assembly can provide greater control over the supply chain and reduce geopolitical risks.

Partnering with Vertically Integrated Manufacturers

Choosing the right manufacturing partner can streamline development and improve system performance. Vertically integrated manufacturers control multiple stages of the production process, from raw materials to final assembly.

-

System-Level Optimization: Vertically integrated partners can engineer thermal camera systems as a matched set, ensuring that the detector, optics, and electronics work together harmoniously. This leads to superior, consistent performance.

-

Faster Customization: These manufacturers often provide more agile customization services, allowing for tailored mechanical interfaces, electrical connections, and form factors that precisely fit your platform.

-

Reduced Development Time: By offering integration-ready solutions and in-house manufacturing of critical components, vertically integrated partners can significantly shorten development cycles and accelerate time-to-market for your advanced surveillance solutions.

When you need thermal imaging that performs reliably under the most demanding conditions, partnering with a manufacturer that offers deep integration support and a secure supply chain is a strategic advantage.

Enhancing Surveillance Capabilities with Advanced Imaging

When your operational needs push beyond the limits of conventional optics, advanced imaging technologies become indispensable. This section examines how tactical drone surveillance, counter-unmanned aircraft systems (C-UAS) operations, and search and rescue (SAR) missions are being revolutionized by advanced thermal and optical imaging solutions.

Tactical Drone Surveillance Applications

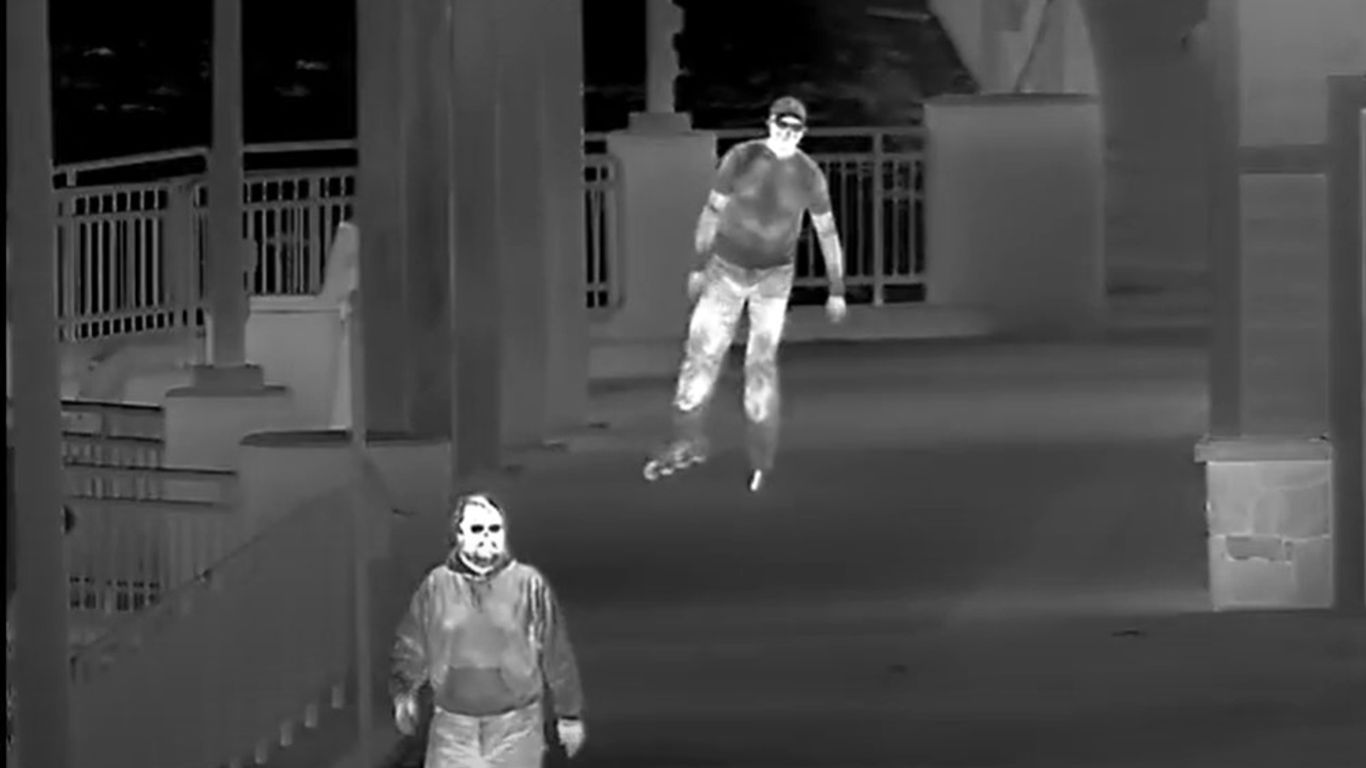

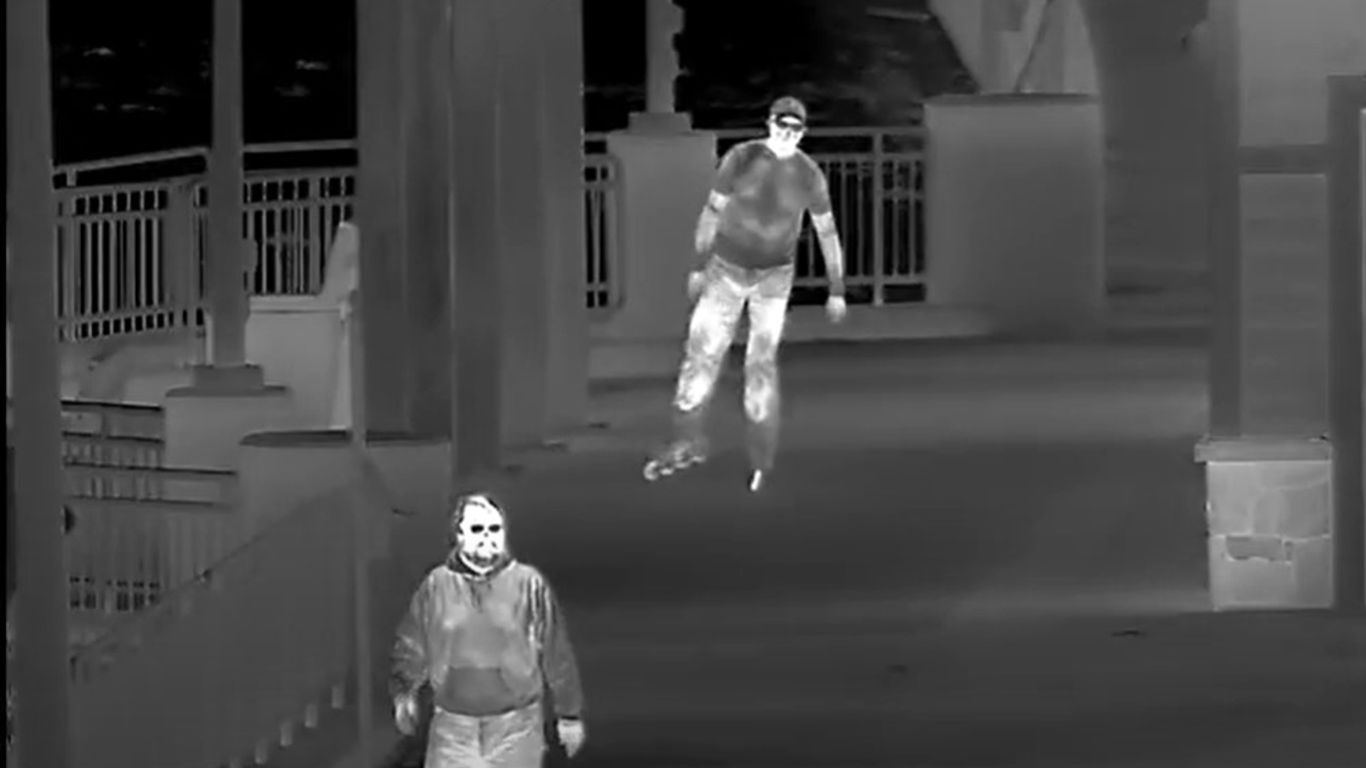

Thermal imaging has become a cornerstone for tactical drone surveillance, providing critical intelligence in scenarios where visible light cameras fall short. These systems detect heat signatures, allowing for the identification of personnel, vehicles, and other heat-emitting objects regardless of ambient light conditions. This capability is vital for intelligence, surveillance, and reconnaissance (ISR) missions, enabling operators to maintain situational awareness in complete darkness, through smoke, or dense foliage.

The selection of the right thermal surveillance camera system is one of the most consequential decisions in platform development, as it directly influences detection range, operational endurance, and overall mission success rates. For program managers and engineering leads, a thermal surveillance camera represents far more than a component; it defines the platform's core capabilities. Partnering with manufacturers who engineer solutions specifically for drone integration, considering size, weight, and power (SWaP) constraints, is key to developing competitive platforms.

Counter-Unmanned Aircraft Systems (C-UAS) Operations

In the evolving landscape of aerial security, counter-unmanned aircraft systems (C-UAS) operations present a unique challenge. Thermal imaging plays a significant role in detecting and tracking unauthorized drones, which often operate covertly. High-sensitivity thermal cameras, characterized by a low Noise Equivalent Temperature Difference (NETD), can distinguish subtle temperature variations, making it easier to identify drones against complex backgrounds.

This advanced temperature sensitivity allows security personnel to accurately detect and track these aerial threats, even in challenging environmental conditions. The ability to provide enhanced situational awareness is paramount for protecting critical infrastructure and securing sensitive areas. Integrating these advanced thermal cameras into C-UAS platforms provides a superior performance edge against unauthorized drone activity.

Search and Rescue Mission Effectiveness

Thermal imaging technology has revolutionized search and rescue (SAR) operations, significantly improving the speed and effectiveness with which missing persons can be located. These systems can detect heat signatures through obscurants like smoke, fog, and dense vegetation, which would render traditional visual cameras ineffective.

For SAR teams, real-time video transmission is critical, allowing ground commanders to see what the drone sees and direct rescue resources immediately. The market for SAR drone technology is projected for substantial growth, reflecting the increasing reliance on these advanced imaging tools. When selecting thermal imaging solutions for SAR, consider systems that offer:

-

Heat Signature Detection: Ability to penetrate smoke, fog, darkness, and dense vegetation to find heat sources.

-

Real-Time Video Downlink: Immediate imagery for tactical decision-making and resource deployment.

-

Durability and Reliability: Systems engineered to perform in varied and often adverse weather conditions encountered during rescue operations.

Choosing the right thermal imaging partner can make the difference between equipment that merely functions and equipment that performs when lives are at stake. You can learn more about advanced imaging solutions by contacting us at https://www.lightpath.com/contact.

Looking Ahead

The world of optical and thermal imaging is really moving fast. These systems are becoming smarter and more resilient, handling everything from freezing cold to scorching heat, and even salty sea air. For anyone involved in surveillance, whether for security, industrial inspections, or locating missing individuals, staying up-to-date with these changes is crucial. The technology is becoming increasingly accessible, but selecting the right gear still matters a great deal. It’s about picking what works best for your specific job, not just grabbing the fanciest gadget. So, as you consider your next project or upgrade, remember that the right imaging tools can make a significant difference in how effectively you can monitor things. Talk to optical and thermal imaging experts at LightPath.com.

Frequently Asked Questions

What's the main difference between the two types of heat cameras, LWIR and MWIR?

Think of it like different kinds of glasses for seeing heat. LWIR (Long-Wave Infrared) cameras excel at detecting heat from objects that are not extremely hot, such as people or animals, and they function effectively even in the presence of light fog or haze. MWIR (Mid-Wave Infrared) cameras are better suited for detecting heat from extremely hot objects, such as engines or machinery, and they provide a clearer picture in certain situations. However, they can be more expensive and are sensitive to weather conditions.

Does a camera with more pixels (higher resolution) always produce better images?

Not necessarily! For searching large areas, a camera with a wider view, even if it has fewer pixels, may be better at spotting something far away. More pixels are helpful for getting a really close look to be sure of what you've found, but covering more ground first is often more important for finding things.

How long can a drone fly with a thermal camera on it?

The type of camera makes a big difference. Lighter cameras that don't use as much power, known as 'uncooled' systems, enable drones to fly for much longer. This means they can search bigger areas over time, which can be more useful than a shorter flight with a super-detailed but power-hungry camera.

Can thermal cameras see through walls or other solid objects?

No, thermal cameras cannot see through solid walls or most materials. They work by detecting the heat that objects emit, which is radiated from their surface. So, while they can see a person through smoke or fog, they can't see through something like a brick wall.

Are thermal cameras useful at night or in bad weather?

Yes, that's one of their biggest advantages! Thermal cameras don't need visible light to work. They detect heat, so they can create clear images even in total darkness. They can also see better than regular cameras through things like fog, smoke, and light rain because the heat they detect travels differently through the air.

What does 'radiometric capability' mean for a thermal camera?

Radiometric capability means the camera can accurately measure the temperature of everything it sees. Many cameras can indicate where it's hotter or colder, but only radiometric cameras can provide precise temperature readings. This is particularly important for jobs such as checking for overheating equipment or detecting heat leaks in buildings.