Understanding BBIR, LWIR, MWIR, and LWIR Cameras: A Comprehensive Comparison

All of the thermal imaging acronyms, such as LWIR, MWIR, and BBIR, can get a little confusing. This article aims to clarify things. We'll break down what these different types of infrared cameras are all about, how they work, and where you'd actually use them. Think of this as your straightforward guide to understanding BBIR vs LWIR vs MWIR vs LWIR cameras, without all the overly technical jargon.

Key Takeaways

-

Deciding between LWIR and MWIR cameras really comes down to what you need to see and where you'll be using the camera. It affects how well your system works and how much it costs.

-

The specific wavelengths used by each camera type are important. LWIR cameras are generally better for seeing things at normal temperatures, while MWIR cameras are often used for hotter objects.

-

The camera's performance in various weather conditions, such as fog or humidity, varies depending on whether it uses LWIR or MWIR technology. This can be a big deal for outdoor use.

-

The way the camera is built, especially whether it requires cooling or not, makes a significant difference in its ease of use, power consumption, and overall cost.

-

Sometimes, you might need a camera that can see in more than one infrared band, or you might need to carefully pick between LWIR and MWIR based on what's most important for your specific job.

Understanding Infrared Spectrum Bands

The electromagnetic spectrum contains a range of wavelengths that are invisible to the human eye but can be detected by specialized sensors. Infrared (IR) radiation falls within this spectrum, and it's the heat emitted by objects that thermal imaging cameras capture. Different parts of the IR spectrum are sensitive to different temperature ranges, leading to the categorization of cameras into specific bands like Long-Wave Infrared (LWIR) and Mid-Wave Infrared (MWIR). Broad-Band Infrared (BBIR) systems, while less common as a distinct category, often refer to systems capable of capturing a wider range of IR wavelengths or integrating multiple bands.

Defining Long-Wave Infrared (LWIR)

Long-Wave Infrared (LWIR) cameras operate in the wavelength range of approximately 8 to 14 micrometers (µm). This band is particularly effective for detecting objects at ambient temperatures, such as people, animals, buildings, and most industrial equipment. The reason LWIR is so well-suited for these applications is that objects at typical terrestrial temperatures emit the majority of their thermal radiation within this specific wavelength range. This characteristic enables LWIR cameras to clearly detect heat signatures, even in complete darkness, without requiring any external light source.

Many LWIR systems utilize uncooled microbolometer detectors, which operate at room temperature. This design simplifies integration, reduces power consumption, and lowers overall system cost compared to cooled alternatives. For many surveillance, security, and industrial monitoring tasks, LWIR provides the necessary performance at a more accessible price point.

Defining Mid-Wave Infrared (MWIR)

Mid-Wave Infrared (MWIR) cameras typically cover the wavelength range of 3 to 5 micrometers (µm). This band is optimized for detecting objects that are significantly hotter than their surroundings, such as vehicle engines, exhaust plumes, or industrial furnaces. The physical principle behind this is that hotter objects emit more energy at shorter wavelengths. MWIR sensors can provide excellent contrast when imaging high-temperature targets against cooler backgrounds. However, achieving high sensitivity in the MWIR band often requires cooled detector arrays. This cooling mechanism, usually a Stirling cooler, adds complexity, size, weight, power consumption, and cost to the system.

MWIR cameras are generally more expensive than their LWIR counterparts. They are often chosen for applications where detecting extremely hot objects at a distance or discerning subtle temperature differences in specific scenarios is crucial, such as in certain defense or high-temperature industrial process monitoring.

Defining Broad-Band Infrared (BBIR)

Broad-Band Infrared (BBIR) is not a strictly defined spectral band in the same way as LWIR or MWIR. Instead, it generally refers to systems or detectors that can capture thermal radiation across a wider range of infrared wavelengths, potentially encompassing parts of both LWIR and MWIR, or even extending beyond these common bands. Sometimes, BBIR might describe a single detector technology that has a broad spectral response, or it could refer to systems that combine multiple sensors to cover different parts of the IR spectrum.

The advantage of a broadband approach can be increased flexibility in detecting a wider variety of thermal signatures or operating effectively under more diverse environmental conditions. However, achieving optimal performance across a very wide spectrum can be challenging, and such systems may involve trade-offs in sensitivity or specificity compared to band-optimized cameras. For many applications, selecting either LWIR or MWIR, or even a dual-band system, provides a more targeted and cost-effective solution than a broadband approach unless specific requirements necessitate it.

Core Principles of LWIR vs MWIR vs BBIR Cameras

Understanding the fundamental differences between Long-Wave Infrared (LWIR), Mid-Wave Infrared (MWIR), and Broad-Band Infrared (BBIR) cameras is key to selecting the right technology for your application. These distinctions primarily revolve around the specific wavelengths of infrared radiation they detect, which in turn dictate their performance characteristics and suitability for various tasks.

Wavelength Ranges and Emission Peaks

Every object with a temperature above absolute zero emits thermal radiation. The peak wavelength of this emission is directly related to the object's temperature. This physical principle is the bedrock upon which LWIR and MWIR technologies are built.

-

MWIR (Mid-Wave Infrared): Typically operates in the 3 to 5 micrometer (µm) range. Objects at higher temperatures, such as engines, machinery in operation, or even hot gases, emit most strongly in this band. This makes MWIR cameras particularly effective for detecting heat sources that are significantly warmer than their surroundings.

-

LWIR (Long-Wave Infrared): Generally covers the 8 to 14 micrometer (µm) range. Objects at or near ambient temperatures, like people, buildings, and most industrial equipment under normal operating conditions, emit their peak radiation within this spectrum. This makes LWIR cameras the workhorse for general surveillance, security, and predictive maintenance, where the goal is to detect objects at typical environmental temperatures.

-

BBIR (Broad-Band Infrared): This term is less standardized and can refer to systems designed to capture a wider range of infrared wavelengths, potentially encompassing both MWIR and LWIR bands, or even extending into other parts of the infrared spectrum. The specific wavelength coverage will depend on the sensor technology and optical design. BBIR systems aim for versatility, though they may not achieve the same peak performance in a specific band as a dedicated LWIR or MWIR camera.

Temperature Sensitivity and Detection Capabilities

The chosen wavelength band directly influences a camera's sensitivity and the range of wavelengths it can effectively detect.

-

MWIR: Due to the emission peaks of hotter objects, MWIR cameras can be highly sensitive to subtle temperature differences in these hotter targets. Cooled MWIR systems, in particular, can achieve very low Noise Equivalent Temperature Difference (NETD) values, allowing for the detection of minute thermal variations even at longer distances. This is advantageous for applications requiring the identification of small heat signatures from distant, hot sources.

-

LWIR: LWIR cameras are optimized for detecting objects at ambient temperatures. While uncooled LWIR systems might have a slightly higher NETD compared to cooled MWIR systems, they offer excellent sensitivity for detecting human targets, identifying thermal anomalies in buildings, or monitoring industrial equipment operating within typical temperature ranges. The ability to detect these objects without requiring extreme cooling makes them more practical and cost-effective for many applications.

-

BBIR: The sensitivity of a BBIR camera will depend on its specific spectral coverage. If it covers both MWIR and LWIR, it can potentially detect a wider range of temperatures. However, the overall sensitivity might be a compromise compared to a camera optimized for a single band, especially if the detector technology is not specifically designed for broad-spectrum performance.

Physical Principles of Thermal Radiation

All objects above absolute zero emit electromagnetic radiation. The intensity and spectral distribution of this radiation are governed by Planck's Law, which relates the emitted radiance to the object's temperature and the wavelength of the radiation.

-

Wien's Displacement Law: This law states that the peak wavelength of emitted radiation is inversely proportional to the temperature of the object. As an object gets hotter, its peak emission shifts to shorter wavelengths. This is why hotter objects peak in the MWIR range, while cooler, ambient temperature objects peak in the LWIR range.

-

Stefan-Boltzmann Law: This law states that the total energy radiated per unit surface area of a black body is directly proportional to the fourth power of the black body's absolute temperature. This means that warmer objects radiate significantly more energy than cooler objects.

-

Atmospheric Transmission: The Earth's atmosphere absorbs and scatters infrared radiation differently across various wavelengths. Both LWIR and MWIR bands have specific atmospheric transmission windows where radiation passes through with less attenuation. However, factors like water vapor, carbon dioxide, and aerosols can affect transmission. MWIR can sometimes perform better in humid conditions, while LWIR may offer advantages in environments with certain types of smoke or dust. BBIR systems would need to consider the transmission characteristics across their entire spectral range.

Understanding these core principles allows you to make informed decisions about which infrared technology best suits your operational needs. For more detailed discussions on how these principles apply to specific applications and system design, please contact us at https://www.lightpath.com/contact.

Performance Characteristics and Operational Advantages

When evaluating thermal imaging technologies, understanding how they perform in real-world conditions is crucial for matching their capabilities with your operational needs. This involves looking beyond basic specifications to consider sensitivity, how well they work in different environments, and how they handle daylight.

Sensitivity and Noise Equivalent Temperature Difference (NETD)

Sensitivity is a measure of how well a camera can detect small temperature differences. This is often quantified by the Noise Equivalent Temperature Difference (NETD). A lower NETD value indicates a more sensitive camera, capable of distinguishing finer thermal details.

-

MWIR Cameras: Generally, Mid-Wave Infrared (MWIR) systems, especially those using cooled detector arrays, can achieve superior sensitivity. High-performance MWIR cameras can detect temperature differences as low as 20 millikelvin (mK). This level of sensitivity is beneficial for detecting subtle temperature variations or for long-range detection where thermal contrast diminishes with distance. However, this often comes with increased system complexity and cooling requirements.

-

LWIR Cameras: Long-Wave Infrared (LWIR) systems, particularly uncooled variants, typically exhibit sensitivity in the 30 to 50 mK range. While this is adequate for many surveillance and monitoring tasks, cooled LWIR systems can also offer enhanced sensitivity for specialized applications.

-

Practical Considerations: Modern thermal imaging development often prioritizes application-specific optimization. Machine learning integration enables cameras to tailor their detection capabilities to specific operational requirements, recognizing that real-world constraints, such as power availability and deployment scenarios, can be more critical than laboratory specifications.

Atmospheric Transmission and Environmental Performance

The performance of a camera is significantly influenced by atmospheric conditions. The interaction of different wavelengths with atmospheric components like water vapor, smoke, and dust plays a vital role.

|

Atmospheric Condition |

MWIR Performance |

LWIR Performance |

Primary Consideration |

|---|---|---|---|

|

High Humidity/Haze |

Generally Better |

More Variable |

Water vapor absorption affects both, but impacts differ. |

|

Smoke/Particulates |

More Variable |

Often Better |

Particle size and density matter as much as wavelength. |

|

Clear Conditions |

Excellent |

Excellent |

Both perform well; other factors become more important. |

|

Maritime Environments |

Generally Preferred |

Can Be Challenging |

Salt spray and humidity often favor MWIR. |

-

MWIR: MWIR imaging often performs better in humid conditions and environments with fine aerosols. Its shorter wavelength experiences different scattering characteristics from water vapor, helping to maintain image quality in coastal or tropical climates.

-

LWIR: LWIR technology can offer advantages in environments with larger suspended particles, such as certain types of smoke, dust, and fog. However, performance here varies significantly based on particle size distribution and density.

-

Selection Factor: Neither technology provides a universal solution for all atmospheric conditions. Your specific operational environment is a crucial factor in selecting the most suitable system.

Daytime Operation and Solar Reflection Interference

Thermal cameras detect emitted heat, not reflected light, which allows them to operate in complete darkness. However, during the daytime, solar radiation can interfere with thermal imaging, especially for MWIR systems.

-

Solar Reflection: Direct sunlight can heat up surfaces, creating thermal signatures that might mask or be confused with the actual targets you are trying to detect. This is particularly true for MWIR systems, which are more sensitive to reflected solar energy.

-

LWIR Advantage: LWIR systems generally experience less interference from solar reflection compared to MWIR systems. This makes them more suitable for continuous day and night operation without significant image degradation due to sunlight.

-

Passive Detection: Both LWIR and MWIR cameras are passive sensors. They do not emit any signals, which is advantageous for covert operations and avoids compromising operational security, unlike active IR illumination systems.

To determine the best fit for your specific needs, consider these performance characteristics in conjunction with your intended operational environment and target types. If you need assistance in selecting the right infrared solution, reach out to us at https://www.lightpath.com/contact.

Application-Specific Use Cases for Infrared Cameras

Infrared cameras, particularly those operating in the Long-Wave Infrared (LWIR) spectrum, have become indispensable tools across a variety of demanding sectors. Their ability to detect thermal signatures, regardless of ambient light conditions, provides unique advantages that traditional imaging cannot match. Understanding where these cameras excel can help you identify the right solution for your specific operational needs.

Defense and Military Applications

In defense and military operations, the need for reliable, long-range detection and surveillance is paramount. LWIR cameras are extensively utilized for their capability to see through obscurants like smoke, fog, and dust, which are common on the battlefield or during adverse weather conditions. They are critical for:

-

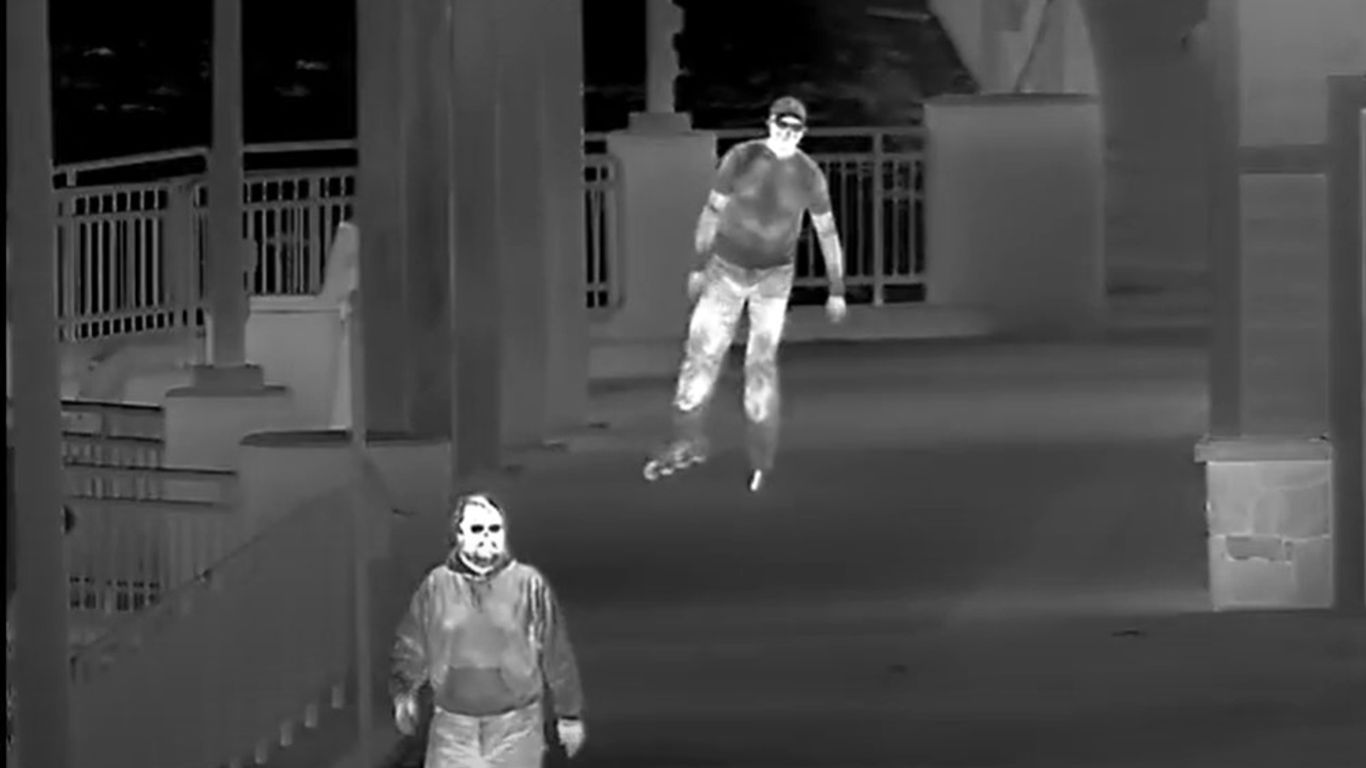

Perimeter Security and Force Protection: Detecting intruders or potential threats at extended distances, day or night, without external illumination. This capability is vital for securing bases, checkpoints, and critical infrastructure.

-

Situational Awareness: Providing real-time thermal imagery to commanders and operators, allowing them to understand the environment and identify potential hazards or targets that might be hidden from visible light cameras. This includes identifying active vehicles, personnel, and even recently fired weapons.

-

Target Identification and Tracking: LWIR systems can aid in identifying and tracking enemy combatants or vehicles by their heat signatures, even when they are camouflaged or attempting to conceal themselves. This is a key aspect of modern defense systems.

-

Counter-Drone Operations: Detecting small, low-heat signature drones against various backgrounds, especially when they are not actively emitting heat from engines. The thermal contrast provided by LWIR is often sufficient for early detection.

Industrial Monitoring and Predictive Maintenance

Within industrial settings, infrared cameras offer a non-contact method for monitoring equipment health and identifying potential failures before they occur. This proactive approach minimizes downtime and prevents costly repairs.

-

Electrical System Inspection: Identifying overheating components in electrical panels, transformers, and power distribution systems. Hot spots often indicate loose connections, overloaded circuits, or failing components.

-

Mechanical Equipment Monitoring: Detecting abnormal heat signatures in rotating machinery such as motors, pumps, and bearings. Elevated temperatures can signal friction, lubrication issues, or impending mechanical failure.

-

Process Monitoring: Observing high-temperature industrial processes, such as furnaces, kilns, and chemical reactions, to ensure they are operating within specified parameters and to identify any anomalies that could lead to safety hazards or product defects.

-

Building Envelope Analysis: Inspecting buildings for insulation deficiencies, air leaks, and moisture intrusion, which can be visualized as temperature differences on surfaces.

Surveillance, Security, and Search and Rescue

Beyond military applications, LWIR cameras are widely adopted for general surveillance, security, and emergency response operations due to their all-weather, all-conditions performance.

-

Perimeter Intrusion Detection: Securing commercial properties, critical infrastructure, and sensitive areas by detecting movement and identifying individuals or vehicles attempting unauthorized entry, even in complete darkness or poor weather.

-

Law Enforcement: Assisting officers in nighttime operations, suspect tracking, and crime scene investigation by revealing thermal signatures that are invisible to the naked eye or standard cameras.

-

Search and Rescue (SAR): Locating missing persons in wilderness areas, at sea, or in disaster zones. The human body's heat signature stands out against cooler backgrounds, making LWIR cameras invaluable for SAR teams, especially when visibility is limited by darkness, fog, or dense foliage.

-

Firefighting: Identifying the hottest parts of a fire, locating hidden embers within structures, and assessing structural integrity by detecting temperature variations. This helps firefighters make informed decisions and operate more safely.

By understanding these diverse applications, you can better appreciate the versatility and critical role of LWIR camera technology. If you are considering integrating such a system, reaching out to experts can provide tailored guidance.

Integration and System Design Considerations

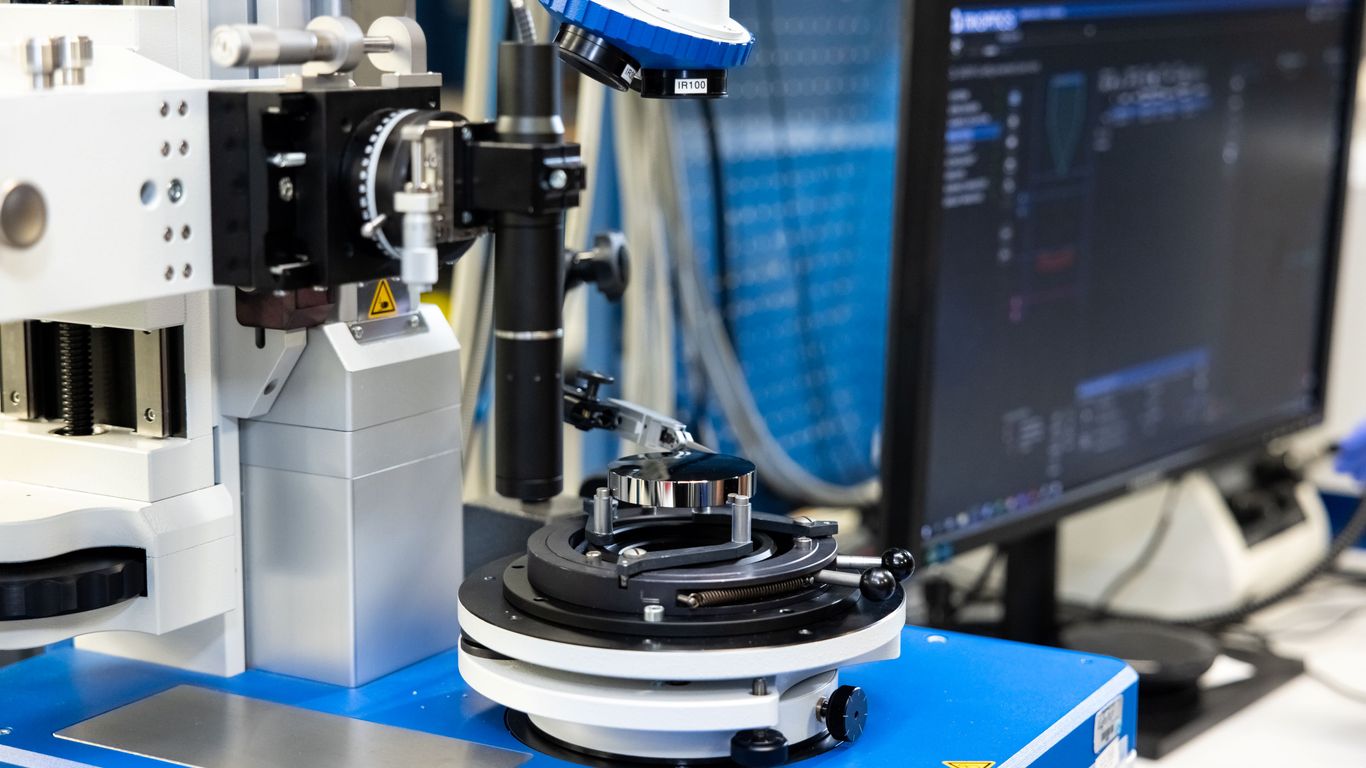

Integrating thermal imaging technology into your system requires careful thought about how the chosen camera architecture and optical design will perform within your specific operational context. Beyond the core performance metrics, factors like detector type, optical characteristics, and interface compatibility significantly influence system complexity, cost, and overall effectiveness.

Uncooled vs. Cooled Detector Architectures

The choice between uncooled and cooled detector architectures presents a primary system design consideration, directly impacting size, power consumption, cost, and performance. Uncooled detectors, commonly microbolometers used in LWIR systems, operate at ambient temperatures. This approach simplifies system design considerably by eliminating the need for cryogenic cooling systems.

Consequently, uncooled systems are generally smaller, lighter, consume less power (typically 2-5 watts), and have a lower initial cost and total cost of ownership. They also require less maintenance due to fewer moving parts. However, uncooled systems typically offer lower sensitivity (e.g., 30-50 mK NETD) compared to their cooled counterparts.

Cooled detectors, often used in high-performance MWIR systems, require cryogenic cooling to achieve optimal operating temperatures. This cooling process significantly enhances detector sensitivity, enabling detection of very small temperature differences (below 20 mK NETD). These systems are essential for applications that demand the highest levels of thermal detail or long-range detection, where thermal contrast is minimal.

However, cooled systems are larger, heavier, consume more power (tens of watts), are more complex, and carry a higher price tag and maintenance burden. The choice hinges on whether the enhanced sensitivity justifies the increased system complexity and operational cost for your application.

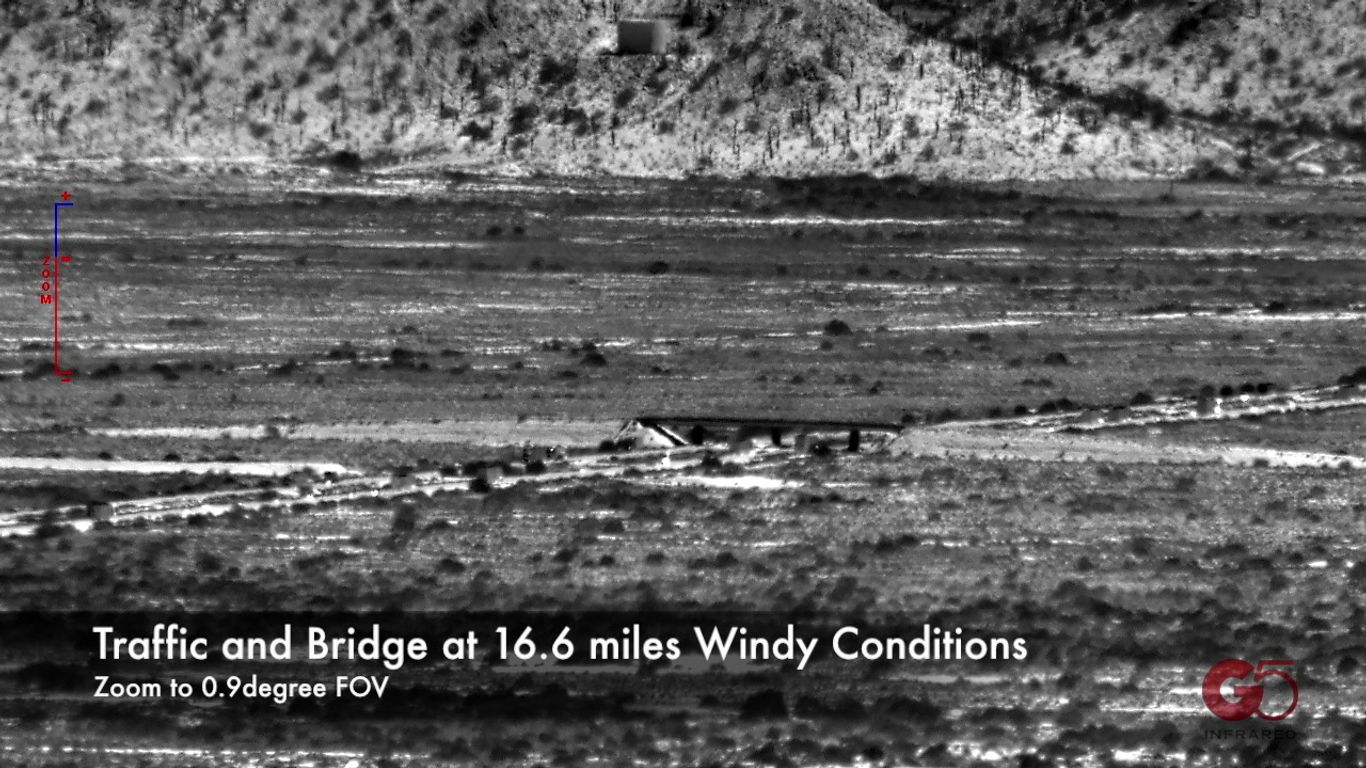

Optical Design and Instantaneous Field of View (IFOV)

The optical design is as critical as the detector itself in determining a thermal camera's performance. Key optical parameters include focal length, f-number, and modulation transfer function (MTF). These elements, combined with sensor resolution, define the Instantaneous Field of View (IFOV) per pixel. IFOV is a measure of the smallest detail a single pixel can resolve at a given distance. A smaller IFOV means higher spatial resolution and the potential for detecting finer details or smaller targets at greater ranges.

For instance, a 320x240 resolution camera with a 25mm lens might achieve a smaller IFOV and thus better long-range detection than a 640x512 camera with a 13mm lens, even though the latter has more pixels. It is a common misconception that higher sensor resolution alone guarantees superior detection. The interplay between sensor resolution and optical design is paramount.

Athermalization, the process of ensuring the optical system maintains focus across a range of temperatures, is vital for consistent performance in varying environmental conditions. When selecting optics, consider the trade-offs between field of view, detection range, and the ability to resolve critical details, all of which are influenced by the IFOV.

Cost, Complexity, and Total Cost of Ownership

When evaluating thermal imaging solutions, it is essential to consider not only the initial purchase price but also the total cost of ownership (TCO). This includes factors such as integration effort, power requirements, maintenance, and potential upgrade paths. Uncooled LWIR systems generally present a lower TCO due to their inherent simplicity, lower power draw, and reduced maintenance needs. Their integration is often more straightforward, leading to shorter development cycles.

Cooled MWIR systems, while offering superior sensitivity, come with a higher TCO owing to the complexity of the cooling system, increased power consumption, and more frequent maintenance requirements. Export control regulations can also add complexity and cost, as certain performance parameters (e.g., frame rates above 9 Hz, specific resolutions) for both LWIR and MWIR systems may trigger export restrictions, necessitating careful specification and compliance management. Partnering with manufacturers who provide comprehensive integration support, standardized interfaces (like GigE Vision, USB3, MIPI CSI-2), and navigating export regulations can significantly reduce development time and mitigate technical risks, ultimately lowering the overall TCO for your project.

Strategic Selection for Optimal Thermal Imaging

Choosing the right thermal imaging technology is a critical step in system design. It's not just about picking the camera with the highest specifications; it's about aligning those specifications with your specific operational needs and environmental conditions. This involves a careful evaluation of performance requirements, integration challenges, and the total cost of ownership.

Balancing Performance Needs with Operational Realities

When selecting between Long-Wave Infrared (LWIR) and Mid-Wave Infrared (MWIR) technologies, consider the primary targets and their typical temperatures. LWIR cameras excel at detecting objects at or near ambient temperatures, making them ideal for surveillance, security, and general monitoring tasks. They operate effectively in complete darkness and can penetrate obscurants, such as smoke and fog, more effectively than some other technologies.

MWIR, on the other hand, is often preferred for detecting hotter objects, such as engines or industrial processes, and can offer better performance in certain humid conditions. However, MWIR systems typically come with higher costs and greater complexity, often necessitating the use of cooling systems.

-

Target Temperature: Are you looking for people and vehicles at ambient temperatures (LWIR), or hot machinery and exhaust (MWIR)?

-

Environmental Conditions: Will your system operate in fog, smoke, or high humidity? LWIR generally performs better in smoke, while MWIR can have an edge in high humidity.

-

Detection Range: While both can offer long ranges, the specific application and target temperature will influence which band provides superior performance at distance.

The Role of Dual-Band and Multi-Spectrum Systems

For applications demanding maximum flexibility, dual-band or multi-spectrum systems offer a compelling solution. These systems combine capabilities from different infrared bands, allowing them to adapt to a wider range of scenarios. For instance, a system might integrate both LWIR and MWIR sensors to provide comprehensive situational awareness across a range of temperatures and atmospheric conditions. This approach can mitigate the limitations of a single-band system, providing more robust performance in diverse operational environments. While these systems can increase complexity and cost, they may be the most effective choice when operational requirements are varied and demanding.

Choosing the Right Infrared Solution: LWIR vs MWIR vs BBIR Cameras

Ultimately, the selection process hinges on a thorough understanding of the unique demands of your application. For most common surveillance, security, and industrial monitoring tasks where detecting objects at ambient temperatures is key, LWIR imaging provides a cost-effective and highly capable solution. Its ability to operate in total darkness and its resilience to environmental obscurants make it a workhorse for many applications.

MWIR finds its niche in specialized scenarios that require the detection of extremely hot targets or specific atmospheric conditions. Broad-Band Infrared (BBIR) systems, while less common in specific band discussions, generally refer to systems capable of capturing a wider range of infrared wavelengths, potentially offering flexibility but often with trade-offs in sensitivity or specificity compared to band-optimized cameras. Carefully weighing these factors against your project's constraints will lead to the optimal thermal imaging solution.

Wrapping Up Your Thermal Imaging Choice

After examining all this, you can see that selecting the right thermal camera is crucial. Whether you're dealing with long-wave infrared (LWIR) or mid-wave infrared (MWIR), each has its own strengths. LWIR is often your go-to for everyday temperatures and situations where things like smoke or fog are around, and it's usually simpler to work with. MWIR, on the other hand, is better suited for spotting extremely hot objects or seeing through certain atmospheric conditions, but it can be more complex.

Consider what you're trying to capture, where you'll be using the camera, and your budget. Getting this right means your system will work the way you need it to, without a lot of hassle. Talk with BBIR, LWIR and MWIR experts at LightPath.com.

Frequently Asked Questions

What exactly is the difference between LWIR and MWIR cameras?

Think of it like different types of glasses for seeing heat. LWIR (Long-Wave Infrared) cameras are like thermal imaging devices that detect heat from objects at normal temperatures, such as people or buildings. MWIR (Mid-Wave Infrared) cameras are better at detecting heat from objects that are significantly hotter, such as engines or furnaces. They look at different 'colors' of heat.

Can you explain what 'Broad-Band Infrared' (BBIR) means?

BBIR is akin to a camera that can detect a wider range of heat 'colors' than just LWIR or MWIR alone. It's designed to capture a broader spectrum of infrared light, which can be useful in certain situations where you need to see a mix of temperatures or different types of heat signatures.

Which type of camera is better for seeing through smoke or fog?

LWIR cameras often perform better in conditions where visibility is limited by smoke, fog, or dust. The 'heat colors' they see can pass through these things more easily than the 'heat colors' that MWIR cameras focus on. For situations such as firefighting or visibility through haze, LWIR is usually the preferred choice.

Do these cameras work in complete darkness?

Yes, absolutely! Thermal cameras, whether LWIR or MWIR, don't need any light to see. They detect the heat that objects naturally give off. So, they work perfectly in total darkness, through smoke, or even when it's very cloudy, because they are seeing heat, not light.

Are cooled cameras better than uncooled cameras?

Cooled cameras (often MWIR) are generally more sensitive and can detect smaller temperature differences, which is ideal for seeing very faint heat signals from a distance. However, they are usually more expensive, bigger, and need more power. Uncooled cameras (often in the LWIR range) are simpler, cheaper, and easier to use for most everyday tasks, such as security or equipment inspection.

When would you choose an LWIR camera over an MWIR camera for a project?

You'd typically choose an LWIR camera when your primary goal is to detect objects at normal temperatures, such as people, animals, or buildings, especially in challenging conditions like fog or darkness. They are also a good choice if you need a more affordable and simpler system. You'd lean towards MWIR if you absolutely need to see very hot objects or need the highest possible sensitivity for very long distances in specific conditions.