The Essential Guide to LWIR Cameras: Applications and Benefits in 2026

You're looking to integrate a thermal imaging system, and the options can seem a bit overwhelming. When you're trying to get a handle on what LWIR cameras can do for your project, it's not about getting lost in the technical details. It's about determining which thermal imaging approach will deliver the performance, reliability, and cost you need to succeed. LWIR imaging has become a go-to solution for thermal detection because it works well in most situations where normal temperatures are required. Whether you're designing a security system, evaluating surveillance gear, or developing new safety equipment, this guide will help you understand the implications of this technology for your work.

Key Takeaways

-

LWIR cameras offer dependable thermal imaging for seeing objects at normal temperatures, useful in defense, aerospace, and industry.

-

These cameras work in the 8-14 micrometer range, spotting heat from objects at regular temperatures without needing extra light or cooling.

-

Uncooled LWIR systems are simpler and cheaper to integrate than cooled MWIR systems, while still performing well for most surveillance and monitoring jobs.

-

The technology is good at seeing through smoke, fog, and dust, and it works reliably in complete darkness.

-

When picking an LWIR camera, you need to think about the target temperature, the environment, how it will be installed, and find a manufacturer that understands custom needs.

Understanding Long-Wave Infrared

(LWIR) Camera Technology

Understanding Long-Wave Infrared (LWIR) camera technology is crucial for selecting the right approach for your specific needs. LWIR imaging captures thermal radiation in the 8- to 14-micrometer range of the electromagnetic spectrum. This specific band is important because objects at typical ambient temperatures, like people, vehicles, and machinery, emit most of their thermal energy within this range. This means LWIR cameras can detect these objects effectively, even in complete darkness, without needing any external light source. It's like seeing heat itself, rather than reflected light.

Fundamentals of LWIR Imaging

LWIR cameras work by detecting the infrared radiation naturally emitted by all objects above absolute zero temperature. The warmer an object, the more energy it radiates. For objects at terrestrial temperatures (from a human body at 37°C to a building at 20°C), the peak emission falls within the LWIR band. This characteristic makes LWIR technology exceptionally well-suited for detecting targets that are not exceptionally hot.

The technology typically employs uncooled microbolometer detectors. These detectors, often made from materials like vanadium oxide or amorphous silicon, change their electrical resistance when struck by infrared radiation. Sophisticated electronics then translate these resistance changes into the thermal images you see. Because these detectors operate at room temperature, they eliminate the need for complex, costly, and maintenance-intensive cryogenic cooling systems often associated with other types of thermal imaging.

The 8-14 Micrometer Wavelength Advantage

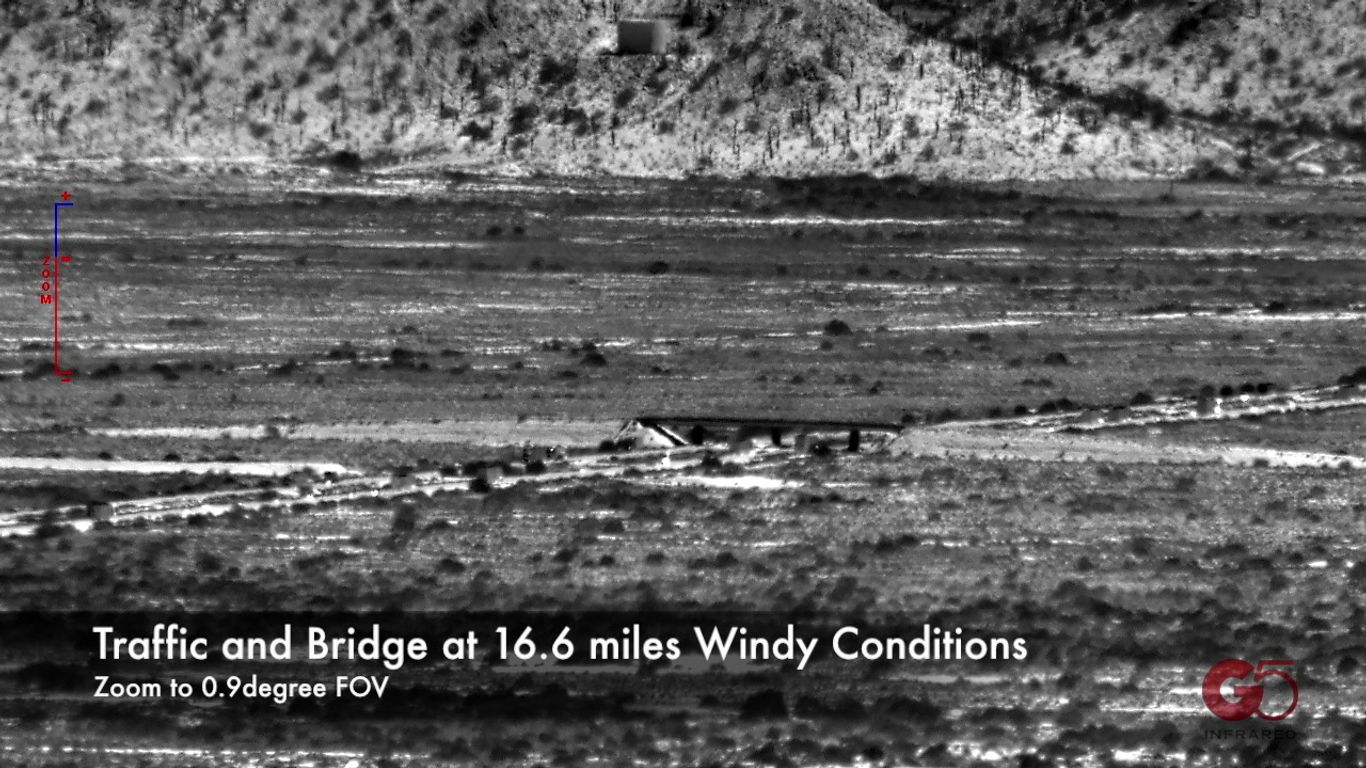

The 8-14 micrometer wavelength range offers distinct advantages for system integration. This band benefits from a broader atmospheric transmission window, meaning LWIR radiation passes through the atmosphere with less interference from water vapor compared to other infrared bands. This enables more reliable performance in diverse environmental conditions, including humid environments.

Furthermore, LWIR radiation penetrates atmospheric obscurants, such as smoke, fog, and dust, more effectively than visible or near-infrared light. This capability is particularly beneficial for applications in challenging conditions where visibility is compromised. For most surveillance and monitoring tasks involving targets at ambient temperatures, this wavelength range provides the necessary performance without the complexity of other technologies.

LWIR vs. MWIR: A Comparative Overview

When evaluating thermal imaging options, the choice between Long-Wave Infrared (LWIR) and Mid-Wave Infrared (MWIR) is a common consideration. Both technologies detect thermal radiation but operate in different wavelength ranges, leading to distinct performance characteristics and cost implications.

|

Feature |

LWIR (8-14 µm) |

MWIR (3-5 µm) |

|---|---|---|

|

Target Temperature |

Optimal for ambient and near-ambient temperatures |

Better for higher temperature targets, or specific gas detection |

|

Atmospheric Penetration |

Good penetration of smoke, fog, dust |

Generally better in very humid conditions, less affected by solar reflection |

|

Detector Type |

Primarily uncooled microbolometers |

Often requires cooling (e.g., Stirling coolers) |

|

System Complexity |

Simpler, lower power, lower cost |

More complex, higher power, higher cost |

|

Sensitivity |

Typically 30-50 mK (uncooled) |

Can achieve <20 mK (cooled) |

While MWIR systems can offer superior sensitivity, especially when cooled, LWIR technology provides a more cost-effective and simpler solution for the vast majority of applications focused on detecting objects at normal operating temperatures. The uncooled nature of most LWIR systems significantly reduces system complexity, power consumption, and overall cost, making them a practical choice for widespread deployment. If your application requires detecting subtle temperature differences at very long ranges or specifically targets high-temperature phenomena, MWIR might be considered. However, for general surveillance, industrial monitoring, and security applications where ambient temperature detection is paramount, LWIR is often the preferred technology. If you need assistance determining the best fit for your specific system requirements, please reach out to us at https://www.lightpath.com/contact.

Key Benefits of LWIR Cameras for System Integration

When integrating thermal imaging into your system, Long-Wave Infrared (LWIR) cameras offer several distinct advantages that can simplify development and enhance overall performance. These benefits directly impact your system's design, cost, and operational reliability.

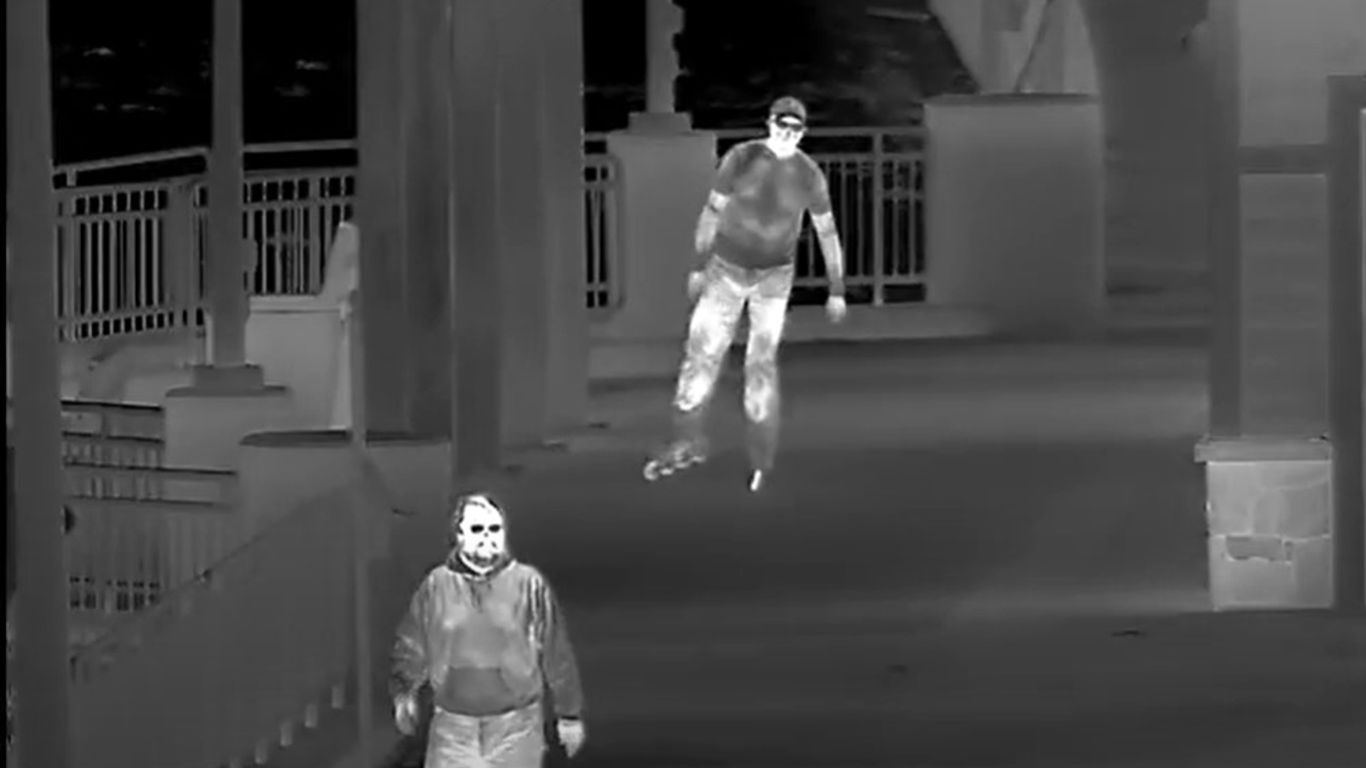

Operation in Total Darkness

LWIR cameras detect thermal radiation emitted by objects, not reflected light. This means your system can see clearly in complete darkness, through smoke, fog, or dust, and even in enclosed spaces with no visible illumination. This passive detection capability is crucial for applications that require covert operations or consistent visibility under all conditions. Unlike visible light cameras, which require external light sources, LWIR systems operate independently of ambient light, providing a constant visual stream.

Penetration of Atmospheric Obscurants

Visible light and even some other infrared wavelengths are scattered by particles in the air, such as smoke, dust, and fog. LWIR wavelengths, however, pass through these obscurants with much less interference. This makes LWIR cameras exceptionally useful for applications in challenging environments, such as firefighting, industrial settings with airborne particulates, or battlefield scenarios where visibility is often compromised. Your system can maintain situational awareness when conventional imaging methods fail.

Uncooled Operation and System Simplification

Many LWIR cameras utilize uncooled microbolometer detectors. This is a significant advantage because it eliminates the need for complex and power-hungry cryogenic cooling systems often required by other thermal imaging technologies. The benefits of uncooled operation include:

-

Reduced Power Consumption: Lower power draw means smaller batteries or less demanding power supplies, which is critical for portable or mobile systems.

-

Smaller Size and Weight: The absence of cooling hardware allows for more compact and lighter camera modules, making integration easier, especially in space-constrained platforms like drones or handheld devices.

-

Lower Maintenance: Without moving parts associated with cooling systems, uncooled cameras generally have fewer points of failure and require less maintenance over their operational life.

-

Faster Startup Time: Uncooled cameras are typically ready to operate almost immediately, without the warm-up period required for cooled detectors.

These factors combine to simplify system design, reduce development time, and lower the total cost of ownership. If your application involves detecting objects at ambient temperatures and does not require extreme sensitivity for very subtle temperature differences at long ranges, LWIR technology offers a practical and cost-effective solution. For more information on how LWIR cameras can benefit your specific system integration needs, please visit https://www.lightpath.com/contact.

Diverse Applications of LWIR Cameras

Defense and Aerospace Surveillance

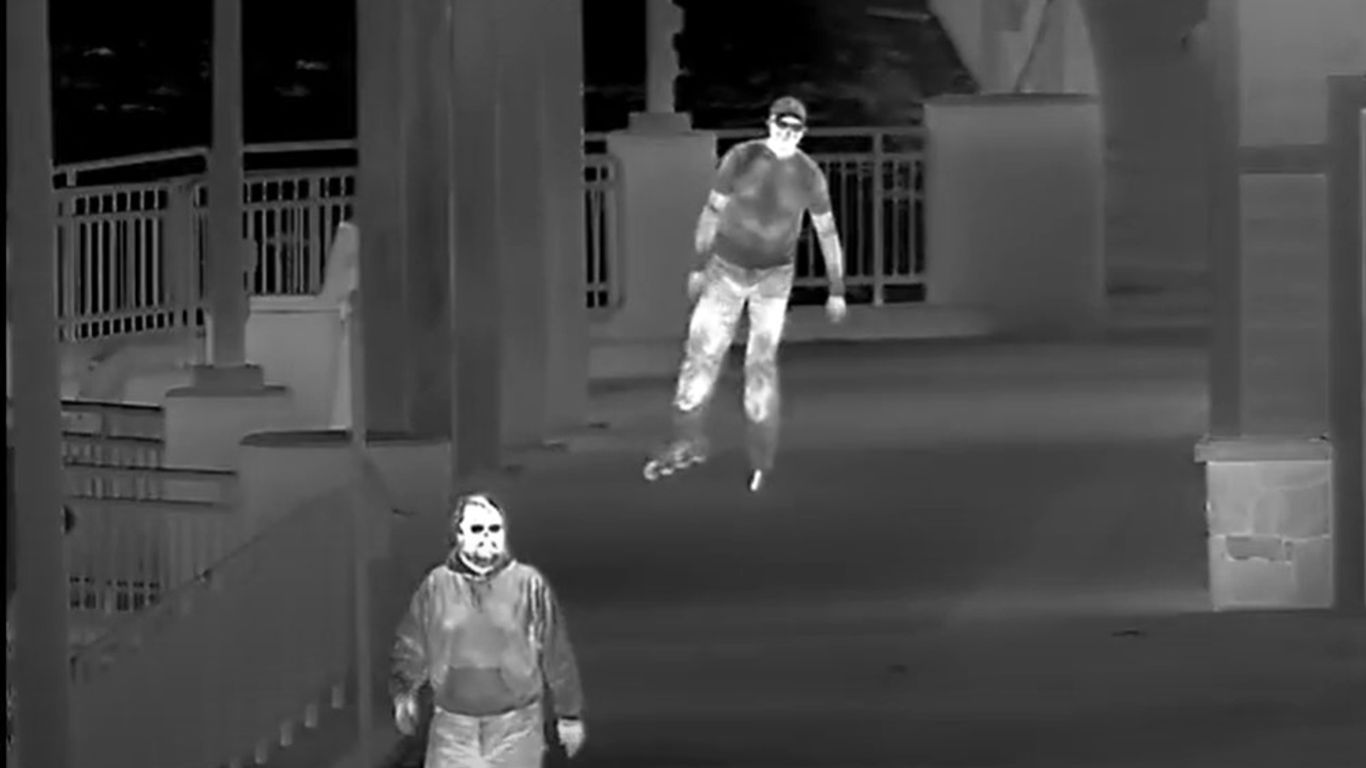

When you're working on defense or aerospace projects, LWIR cameras offer a significant advantage. They can see in complete darkness, which is particularly useful for nighttime operations or when stealth is required. Unlike regular cameras that need light, thermal cameras detect heat signatures. This means they can spot people or vehicles even when there's no visible light. They're also good at seeing through things like smoke, fog, or dust. This capability is vital for battlefield awareness, enabling the identification of threats or monitoring perimeters even in poor visibility conditions. For aircraft or drone integration, their ability to operate passively without emitting signals is a major plus for operational security.

-

Perimeter Security: Detecting intruders around bases or sensitive areas.

-

Situational Awareness: Providing a clear view of the environment for pilots or ground forces.

-

Counter-Drone Systems: Identifying and tracking small, low-heat targets.

-

Reconnaissance: Gathering intelligence day or night, in various weather conditions.

Industrial Monitoring and Predictive Maintenance

In industrial settings, LWIR cameras are becoming increasingly indispensable for maintaining equipment operation and preventing costly failures. You can use them to monitor machinery, electrical systems, and processes without direct contact. For example, you can spot overheating components in electrical panels or motors before they cause a breakdown. This type of predictive maintenance saves a significant amount of money and downtime. They are also useful for monitoring high-temperature processes, such as those in furnaces or kilns, where direct visual inspection is impossible or hazardous. The uncooled nature of many LWIR systems makes them easy to integrate into existing infrastructure or mobile platforms for regular checks.

-

Electrical Inspections: Identifying hot spots in transformers, switchgear, and wiring.

-

Mechanical Monitoring: Detecting bearing wear or motor issues through heat anomalies.

-

Process Control: Observing temperature profiles in manufacturing or chemical processes.

-

Building Envelope Analysis: Finding insulation gaps or moisture issues.

Harsh Environment Deployments

When your application involves extreme conditions, LWIR cameras truly demonstrate their value. Consider systems that must operate in environments with extreme cold, intense heat, or corrosive elements, such as saltwater. Standard cameras often fail in these situations. LWIR cameras, especially those designed for these specific challenges, can maintain reliable performance. They are built with robust materials and designs to withstand these harsh conditions, whether it's for maritime surveillance on a ship, monitoring equipment on an offshore platform, or operating in remote, rugged terrain. Their ability to see through atmospheric obscurants also means they can provide critical data even when visibility is severely limited by weather or airborne particles.

-

Maritime Surveillance: Operating on vessels in corrosive saltwater environments.

-

Extreme Temperature Monitoring: Functioning reliably in both Arctic cold and desert heat.

-

Remote Infrastructure Inspection: Checking assets in inaccessible or dangerous locations.

-

Emergency Response: Providing visibility during wildfires or chemical spills.

Performance Characteristics of LWIR Imaging Systems

When selecting an LWIR camera, understanding its performance characteristics is crucial to ensuring it meets your system's requirements. These characteristics determine how well the camera performs in various conditions and the level of detail it can capture.

Sensitivity and Detection Capabilities

Sensitivity in an LWIR camera refers to its ability to detect small temperature differences. For uncooled LWIR systems, this typically falls within the 30 to 50 millikelvin (mK) range. While this might seem less sensitive than some cooled systems, it is more than adequate for the majority of surveillance and monitoring tasks where you need to identify objects at ambient temperatures. Think about spotting a person at a distance or detecting a heat leak in industrial equipment; this level of sensitivity is precisely what's needed. Cooled LWIR systems do exist, offering higher sensitivity, but they come with increased complexity and cost, making them suitable for more specialized applications.

Reliability Across Temperature Extremes

One of the significant advantages of LWIR technology, particularly uncooled microbolometer-based systems, is their robust performance across a wide range of operating temperatures. You can expect consistent imaging capabilities whether your system is deployed in the frigid conditions of the Arctic or the intense heat of a desert environment. This inherent stability means there is a reduced need for complex internal temperature regulation systems within your platform. Your engineers can focus on other aspects of system design rather than compensating for sensor performance fluctuations due to ambient temperature changes. This reliability directly translates to simpler mechanical designs and reduced maintenance burdens.

Environmental Performance Considerations

LWIR cameras excel in challenging environmental conditions where visible light cameras struggle. Their ability to capture thermal radiation enables them to operate effectively in total darkness, without requiring any external illumination. Furthermore, the 8-14 micrometer wavelength range enables LWIR imaging to penetrate atmospheric obscurants, such as smoke, fog, dust, and light precipitation, much better than visible light. This makes them invaluable for applications such as:

-

Defense and Security: Maintaining situational awareness through smoke screens or during nighttime operations.

-

Industrial Monitoring: Visualizing heat signatures through industrial dust or steam.

-

Emergency Services: Providing visibility for firefighters or search and rescue teams in low-visibility conditions.

This resilience means your system can maintain operational effectiveness across a broader spectrum of real-world scenarios.

Strategic Considerations for LWIR Camera Selection

When you're looking to integrate LWIR cameras into your system, it's not just about picking the one with the highest resolution. You need to consider how it fits into the broader context. This involves considering the costs, the ease of integration with your existing setup, and the long-term implications.

Cost-Effectiveness for Ambient Temperature Detection

For many applications, the primary goal is to detect objects that are roughly the same temperature as their surroundings. Consider security cameras monitoring for people or vehicles, or industrial sensors tracking machinery. LWIR cameras are particularly well-suited for this purpose. They offer strong performance for detecting these kinds of targets without needing complex, expensive cooling systems. This makes them a more affordable choice for widespread deployment.

When you're scaling up a project or managing a budget, this cost advantage is significant. It means you can get the necessary thermal imaging capabilities without breaking the bank. For systems where detecting objects at ambient temperatures is key, LWIR provides a practical and economical solution. For more information on how these cameras integrate into various systems, refer to automotive applications.

Integration and Lifecycle Management

Beyond the initial purchase price, consider the total cost of owning and operating the camera, including maintenance, replacement parts, and other associated expenses. Uncooled LWIR systems, which are commonly used, generally require less power, generate less heat, and have fewer moving parts than their cooled alternatives. This translates to simpler thermal management within your system, reduced maintenance requirements, and an extended operational life.

When you factor in development time, installation complexity, and ongoing support, these aspects become very important. A system that's easier to integrate and maintain will save you time and resources throughout its lifespan. This is especially true for applications where frequent servicing is difficult or costly.

Choosing the Right Manufacturer Partner

Selecting a manufacturer is more than just a transaction; it's about building a relationship. Look for partners who understand your specific needs and can provide support throughout the entire process. This includes:

-

Technical Support: Access to engineers who can help with integration challenges and system optimization.

-

Customization Options: The ability to tailor camera features or interfaces to meet unique project requirements.

-

Supply Chain Reliability: A stable source for components and a commitment to consistent product availability, which is vital for production planning.

-

Long-Term Vision: A partner who is investing in future technology and can support your system's evolution.

Working with a manufacturer that offers a complete ecosystem of support, from initial design to post-deployment service, can significantly de-risk your project and accelerate your time to market. You can explore options and connect with experts at https://www.lightpath.com/contact.

The Evolving Landscape of LWIR Camera Technology

Market Growth and Future Projections

The thermal camera market is seeing significant expansion. Projections indicate a rise from approximately $4.12 billion in 2024 to over $8 billion by 2033. This growth is fueled by advancements in detector technology and increasing demands for advanced monitoring across various sectors. Organizations are increasingly viewing thermal imaging as a necessary component for their operations, not just an optional add-on.

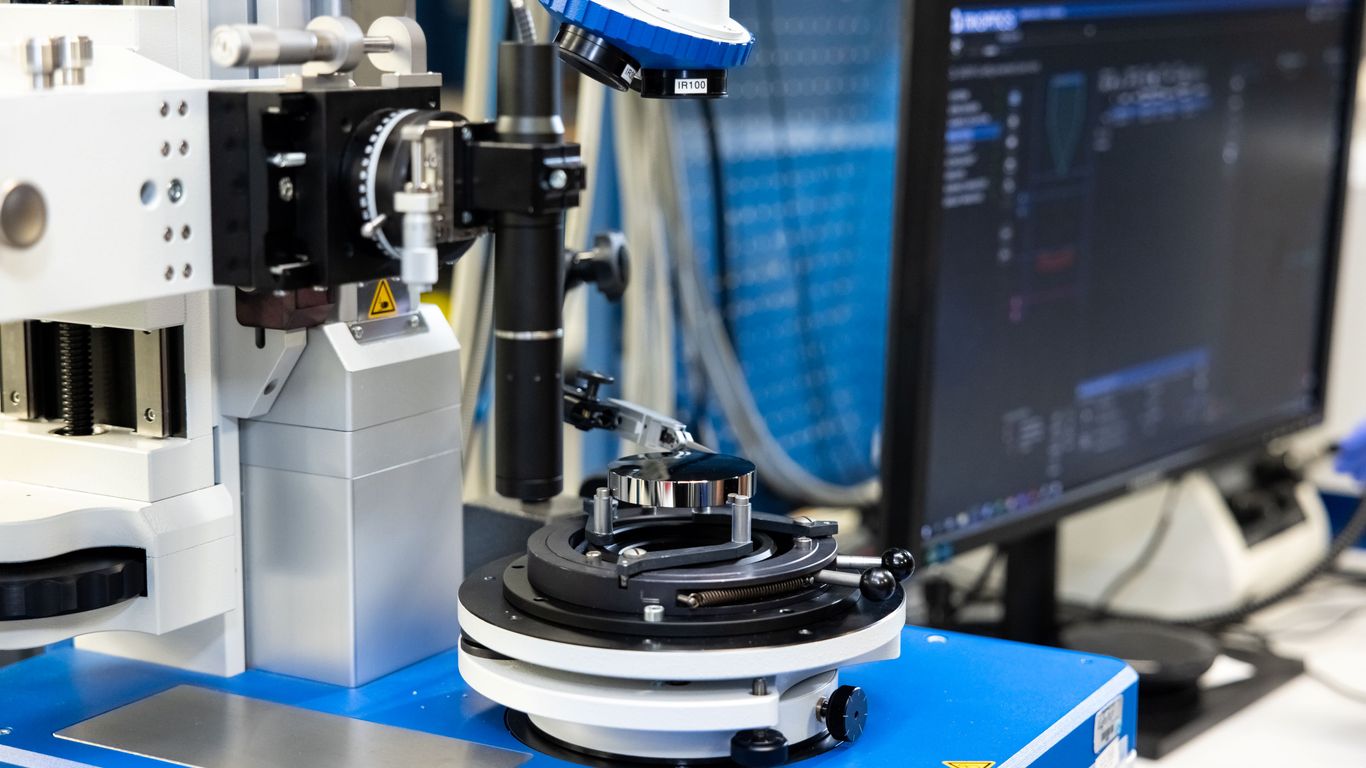

Advancements in Detector Technology

Recent developments in detector technology are making LWIR cameras more capable and accessible. Innovations are leading to improved sensitivity and reduced noise, allowing for clearer images in challenging conditions. Furthermore, these advancements are contributing to more compact and power-efficient designs, which are critical for integration into smaller platforms or systems with limited power budgets.

Custom Integration and OEM Support

For system integrators and Original Equipment Manufacturers (OEMs), the availability of custom integration support is becoming a key differentiator. Many manufacturers now offer services that can significantly shorten development timelines, often reducing them from over 18 months to just a few months. This support can include:

-

Factory Calibration: Ensuring cameras are precisely calibrated for specific applications before delivery.

-

Standardized Interfaces: Providing compatibility with common embedded systems and communication protocols like GigE Vision or MIPI CSI-2.

-

Dedicated Engineering Support: Offering technical assistance throughout the integration process.

Partnering with manufacturers that provide comprehensive support ecosystems can reduce technical risk and accelerate the time-to-market for new products. If you are looking to integrate advanced LWIR solutions, consider reaching out to experts who can guide your development process at https://www.lightpath.com/contact.

The world of LWIR camera technology is always changing. New advancements are making these cameras more effective and useful for various jobs.

Looking Ahead with LWIR Technology

As you've seen throughout this guide, long-wave infrared (LWIR) cameras are no longer a niche technology. They've become a vital tool for various jobs, from surveillance to monitoring industrial equipment. The way these cameras work, by seeing heat instead of light, gives you a significant advantage, especially when conditions are challenging due to bad weather or no light at all.

Additionally, the newer models are becoming easier to integrate into your existing systems and are less expensive than they used to be. So, when planning your next project, consider how LWIR cameras can enhance its effectiveness. It's worth exploring how this technology can help you accomplish your tasks, regardless of the conditions. Talk with LWIR camera experts at LightPath.com.

Frequently Asked Questions

What exactly is LWIR imaging?

LWIR stands for Long-Wave Infrared. Think of it as a special kind of camera that can see heat, not just light. It looks at the world using heat waves that are longer, specifically in the 8 to 14 micrometer range. This lets it see things even when it's completely dark or when there's fog or smoke.

Why is LWIR technology useful for my system?

LWIR cameras are great because they can see in total darkness without needing any lights. They can also see through things like smoke, fog, and dust much better than regular cameras. Plus, many LWIR cameras don't need special cooling, which makes them simpler and cheaper to put into your system.

When should I choose LWIR over other types of thermal cameras?

You should consider LWIR when you need to detect objects that are around normal temperatures, like people, cars, or machinery. It's usually more cost-effective for these kinds of jobs. If you need to see very faint heat differences from far away or look at extremely hot objects, another type called MWIR might be better, but LWIR works for most everyday needs.

Can LWIR cameras work in bad weather or tough conditions?

Yes, absolutely! LWIR cameras are known for working well even when things are tough. They can see through smoke, fog, and light rain because the heat waves they use aren't easily blocked. They also work reliably in very hot or very cold places, making them a dependable choice for difficult environments.

How do LWIR cameras help with industrial tasks?

In industries, LWIR cameras are used for checking equipment before it breaks down. They can spot overheating parts in electrical systems or machinery, helping to fix problems early. They're also used for safety, like checking buildings for heat leaks or monitoring processes that involve heat.

What should I think about when picking an LWIR camera?

When you're choosing an LWIR camera, think about what you need to see (the temperature of your targets), where you'll use it (the environment), and how it needs to fit into your system (size, power, and connections). It's also smart to work with a company that makes these cameras and can help you find the best one or even customize it for you.