Thermal Imaging Camera Systems: The OEM's Guide to Building vs. Buying

Key Takeaways

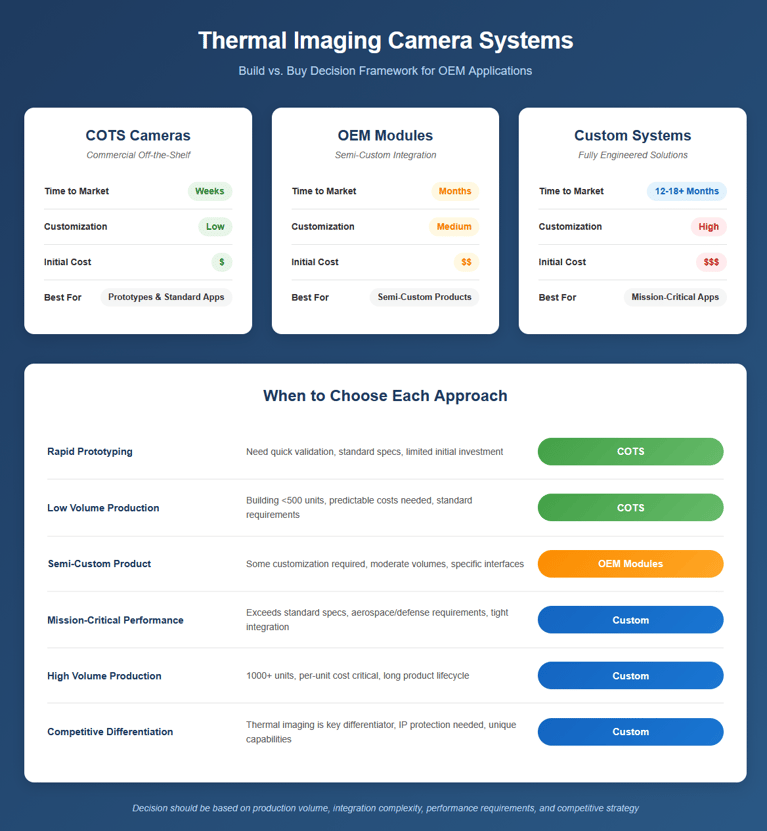

- Choosing between off-the-shelf and custom thermal imaging camera systems impacts your product's performance, time-to-market, and competitive positioning.

- Custom thermal systems deliver superior value for specialized performance requirements, while off-the-shelf solutions work best for standard applications and rapid deployment.

- Production volume, integration complexity, and competitive differentiation determine which approach maximizes long-term value.

The thermal imaging market continues its rapid expansion, with the global market valued at approximately $7.69 billion in 2024 and projected to reach $16.29 billion by 2034. For OEMs developing next-generation products, the critical question is how to acquire thermal imaging capabilities: purchase an off-the-shelf thermal camera or invest in custom thermal systems engineered for your application?

As leading specialized manufacturers advance thermal imaging capabilities, OEMs face increasingly sophisticated options. This camera integration guide examines both paths to help you make the strategic choice that aligns with your program goals based on application requirements, integration timeline, budget parameters, and competitive positioning.

What Defines a Thermal Imaging Camera System?

A thermal imaging camera system includes the infrared detector, optical elements (lenses and filters), image processing electronics, housing, power management, and output interfaces. Systems range from fully integrated commercial cameras ready for deployment to modular OEM cores requiring platform integration.

Consumer-grade handheld thermal cameras are complete, self-contained systems. OEM thermal camera modules provide raw sensor data through standard interfaces, expecting the host platform to handle processing and control. Your requirements determine which integration level makes sense. Applications requiring standard thermal imaging leverage off-the-shelf solutions, while programs demanding specialized configurations benefit from purpose-built systems.

Off-the-Shelf vs Custom: Three Strategic Options

Commercial Off-the-Shelf (COTS) Cameras

Ready-to-deploy thermal cameras offer the fastest deployment path. These complete systems include integrated displays, onboard processing, standardized connectivity, and ruggedized housings. COTS solutions eliminate design work, reduce development risk, and compress time-to-market with proven technology and immediate availability.

However, you're constrained by manufacturer design choices for optics, interfaces, form factors, and features. Integration often requires adapting your platform around the camera's specifications. Performance compromises become inevitable when standard configurations don't perfectly align with application requirements.

OEM Camera Cores and Modules

OEM modules provide core thermal imaging functionality while allowing customization of housing, interfaces, and mechanical integration. This approach offers more flexibility than COTS cameras while avoiding full custom development complexity. You select from various resolution options, lens configurations, and interface standards, with many modules including SDKs and technical support.

The trade-off involves increased engineering effort. Your team handles mechanical design, thermal management, power integration, and often image processing portions. Testing and qualification become your responsibility, but you gain significantly more control over final system characteristics.

Fully Custom Thermal Systems

Custom thermal systems involve comprehensive engineering where optical components, assemblies, and cameras are designed specifically for your application. This includes custom lens designs, proprietary coatings, specialized detector configurations, and optimized electronics.

Custom approaches deliver maximum performance and differentiation. Every element gets engineered to your exact specifications, ensuring optimal platform integration. The investment is substantial, requiring significant engineering resources, longer timelines, and higher upfront costs. However, for programs where performance, integration, or competitive differentiation are paramount, custom thermal systems provide unmatched capabilities.

|

Approach |

Time-to-Market |

Customization |

Initial Cost |

Best For |

|

COTS Cameras |

Weeks |

Low |

$ |

Proof of concept, standard applications |

|

OEM Modules |

Months |

Medium |

$$ |

Semi-custom products, moderate volumes |

|

Custom Systems |

12-18+ months |

High |

$$$ |

Mission-critical, high-performance programs |

When Off-the-Shelf Thermal Cameras Make Sense

Off-the-shelf thermal cameras excel in specific scenarios. Early-stage development and rapid prototyping benefit from commercial cameras that enable quick concept validation without significant investment. When performance requirements align with commercially available specifications, purchasing makes obvious sense.

Low-volume production often cannot justify custom development costs. Engineering investment and tooling expenses get amortized across production quantities. When building dozens or hundreds of units rather than thousands, per-unit custom development costs become prohibitive. Off-the-shelf cameras provide predictable costs regardless of volume.

Budget-constrained programs may require commercial cameras to provide thermal imaging capabilities within tight financial parameters. Delivering a product with commercial-grade thermal imaging often proves more valuable than delaying while pursuing ideal custom solutions.

When Do Custom Thermal Systems Deliver Better Value?

Mission-Critical Performance Requirements

Aerospace, defense, and critical industrial applications often demand performance exceeding standard commercial specifications. Long-range detection, extreme temperature sensitivity, specialized spectral bands, or exacting image quality push beyond mass-market products.

Custom thermal systems optimize every performance parameter without accepting compromises inherent in broad-market designs. Engineering focuses exclusively on your application's demands, whether maximizing detection range, minimizing size and weight, or achieving specific certification standards.

Challenging Integration Environments

Platform constraints frequently make standard camera packages impractical. Tight space envelopes, unusual mounting requirements, specific interface protocols, proprietary electronics integration, or severe environmental conditions complicate commercial product use.

Custom thermal systems design around your integration challenges. Mechanical interfaces, electrical connections, thermal management, and form factors optimize for your platform, eliminating adapter plates and custom housings. Custom designs incorporate preferred communication protocols, synchronize with other sensors, and match power budgets.

Supply Chain Security

Critical programs require assured component availability and supply chain transparency. Commercial cameras face discontinuation or modification as manufacturers adjust product lines. For programs with decade-long lifecycles, this uncertainty creates unacceptable risk.

Custom thermal system manufacturers provide greater control over component sourcing and production continuity. Recent export restrictions on germanium have created supply challenges, making germanium-free alternatives like chalcogenide glass increasingly valuable for long-term program stability.

Competitive Differentiation

Markets where thermal imaging directly impacts competitive positioning justify custom investment. If your thermal system's performance creates meaningful differentiation, using the same commercial cameras as competitors undermines your market position. Custom development builds proprietary advantages and protects intellectual property through unique optical designs, specialized algorithms, or innovative integration approaches.

Key Decision Factors in Your Camera Integration Guide

Technical Requirements Assessment

Start with rigorous definition of actual requirements versus aspirational specifications. Define minimum acceptable performance for resolution, temperature sensitivity, frame rate, and spectral bands. Compare these against available commercial specifications to identify gaps.

Be realistic about your team's expertise. Thermal imaging integration involves specialized knowledge of infrared optics, detector physics, and thermal management. Without in-house expertise, partnering with experienced specialists becomes essential regardless of approach.

Integration Complexity and Resources

COTS cameras require minimal integration work but may demand significant platform adaptation. OEM modules need substantial engineering for integration but offer flexibility. Custom systems require the most development effort but optimize integration.

Consider available resources and timeline constraints. Can you dedicate experienced engineers to thermal integration? Do you have necessary mechanical, electrical, and optical capabilities? Resource constraints make off-the-shelf options or comprehensive partnerships more attractive.

Production Volume and Cost Analysis

Custom development's higher non-recurring costs get distributed across all units produced. At low volumes, per-unit burden is substantial. As volumes increase, amortized development costs become negligible while per-unit savings from optimized designs create significant advantages.

Calculate break-even volumes where custom development equals cumulative commercial camera premiums. Consider both immediate production and projected lifetime volumes across potential programs.

|

Decision Factor |

Questions to Answer |

Impact on Choice |

|

Performance Needs |

Do standard specs meet requirements? |

High impact on custom justification |

|

Integration Constraints |

Can platforms adapt to COTS cameras? |

Drives mechanical customization needs |

|

Production Volume |

Break-even analysis at projected volumes? |

Determines cost-effectiveness of custom |

|

Development Timeline |

How quickly must you deliver? |

Favors COTS for rapid deployment |

|

Competitive Strategy |

Does thermal capability differentiate product? |

Justifies custom for IP protection |

Making the Right Decision

Start with Requirements, Not Solutions

Define comprehensive requirements before evaluating solutions. Document performance parameters, integration constraints, environmental conditions, and certification standards without regard to product availability. Requirements clarity eliminates uncertainty and provides objective decision criteria.

Consider Your Core Competency

If thermal imaging represents critical IP central to competitive advantage, investing in custom development makes strategic sense. If thermal imaging enables your product's primary function, leveraging partners' specialized expertise often proves more effective while you focus on core differentiation.

Evaluate Long-Term Strategic Value

If your roadmap includes multiple products incorporating thermal imaging, investing in custom development platforms adapted across programs creates increasing value. The engineering investment gets leveraged repeatedly. Consider whether thermal imaging will remain central to portfolio competitiveness for years.

Build Flexibility

Many successful programs begin with off-the-shelf thermal cameras for initial launches, then transition to custom systems as volumes grow and requirements crystallize. This staged approach reduces risk while building toward optimized solutions. Flexible partnerships create options as programs mature.

Frequently Asked Questions

How long does it typically take to develop a custom thermal imaging camera system?

Custom thermal imaging development typically requires 12 to 18 months from requirements through production qualification, including optical design, prototyping, testing, and manufacturing setup. OEM module integration typically takes three to six months, while COTS camera integration can be accomplished in weeks.

What resolution thermal imaging camera do I need for my application?

Industrial monitoring often performs adequately with 160×120 or 320×240 resolution. Precision inspection and security benefit from 640×480 resolution. Long-range surveillance and targeting typically demand 1024×768 or higher. Define the smallest temperature difference you must detect at required working distance, then work with specialists to determine appropriate resolution and lens configuration.

Can I start with off-the-shelf and transition to custom later?

Yes, this phased approach successfully manages risk. Initial generations often use commercial cameras to validate market and establish revenue. As volumes grow, transitioning to custom thermal systems optimizes performance and reduces per-unit costs. Ensure early designs don't create dependencies making transitions difficult.

What's the difference between cooled and uncooled thermal cameras?

Uncooled cameras use microbolometer detectors at ambient temperature, making them lighter, compact, power-efficient, and less expensive for most commercial, industrial, and many defense applications. Cooled cameras utilize cryogenically-cooled detectors providing superior sensitivity for advanced military targeting and long-range surveillance. Your application's range and sensitivity requirements determine which technology is appropriate.

How do I ensure long-term parts availability for custom thermal systems?

Work with thermal imaging specialists committing to full lifecycle support through formal supply agreements. Designs incorporating proprietary materials reducing dependence on constrained commodities improve supply security. Establish clear obsolescence management processes with your partner, including notification requirements and transition plans.

Partner with Proven Thermal Imaging Experts

Success depends on choosing the right approach and partnering with organizations bringing genuine expertise. Whether you need off-the-shelf thermal cameras, OEM modules, or custom thermal systems, work with partners understanding both thermal imaging technology and your application domain.

For over four decades, LightPath Technologies has delivered premium optical and thermal imaging solutions to aerospace, defense, and industrial leaders worldwide. With fully integrated capabilities spanning proprietary Black Diamond chalcogenide glass, precision optical components, thermal imaging assemblies, and complete camera systems, LightPath partners with OEMs from concept through production.

Whether your program demands proven technology or custom engineering for unique specifications, LightPath's expertise and comprehensive portfolio ensures access to the right thermal imaging camera system. Contact LightPath's team to discuss your requirements and discover the optimal approach for your program.