Top U.S. Thermal Camera Manufacturers for OEMs and Integrators

Key Takeaways

Selecting the right thermal camera manufacturers can significantly impact product performance, supply chain stability, and time to market for OEMs and system integrators.

- North America represents approximately 35% of the global thermal imaging market, driven by defense spending and industrial demand

- OEMs increasingly seek FLIR alternatives to diversify supply chains and access custom engineering capabilities

- Vertical integration, from raw materials to finished systems, has emerged as a critical differentiator among U.S. thermal camera makers

- Evaluating manufacturers based on customization capabilities, supply chain security, and engineering partnership approach yields better long-term outcomes than focusing solely on specifications

The thermal imaging market continues its steady expansion as aerospace, defense, and industrial applications demand more sophisticated solutions. For OEMs and system integrators, choosing among thermal camera manufacturers involves far more than comparing spec sheets. According to recent market analysis, the infrared imaging market is projected to grow from $8.61 billion in 2025 to $11.65 billion by 2030. This growth creates both opportunity and complexity for organizations building thermal capabilities into their platforms.

Unlike end users shopping for handheld devices, OEMs need partners who understand system integration, can customize solutions for specific applications, and offer supply chain reliability. The landscape of thermal camera manufacturers in the United States has evolved considerably, with several established players and emerging alternatives reshaping how integrators approach sourcing decisions.

What Should OEMs Look for in Thermal Camera Manufacturers?

The selection criteria for thermal camera manufacturers differ substantially based on your role in the supply chain. Product engineers and program managers evaluating suppliers should consider several dimensions beyond the obvious performance specifications.

First, manufacturing depth matters enormously. Some thermal camera manufacturers purchase cores and assemble final products, while others control the entire production process from detector fabrication to final camera assembly. This distinction affects quality consistency, lead times, and your ability to customize solutions for specific applications.

Second, engineering collaboration capability separates transactional suppliers from true partners. The best U.S. thermal camera makers work alongside your engineering team from concept through production, ensuring thermal systems integrate seamlessly into larger platforms. This collaborative approach proves especially valuable in aerospace and defense applications where mission requirements often demand purpose-built solutions.

Third, supply chain transparency has become non-negotiable. Recent global disruptions highlighted vulnerabilities in thermal component sourcing, particularly regarding critical materials like germanium. Thermal camera manufacturers with proprietary materials or domestic sourcing alternatives offer meaningful risk mitigation.

Understanding the U.S. Thermal Imaging Supplier Landscape

The domestic thermal imaging market includes several distinct categories of suppliers, each bringing different strengths to OEM and integrator partnerships.

Large defense contractors often incorporate thermal imaging within broader electro-optical and infrared portfolios. These organizations typically excel at complex government program requirements and large-scale defense integrations, though their size can sometimes limit flexibility for smaller custom projects.

Diversified technology conglomerates serve wide market ranges from consumer products to military applications. Their extensive product catalogs offer breadth, while their scale can provide production capacity advantages for high-volume requirements.

Specialized OEM-focused manufacturers concentrate specifically on serving system integrators and product developers. These partners typically emphasize custom engineering collaboration, vertical integration from materials through finished systems, and flexibility that larger organizations may not provide.

Emerging thermal technology companies have expanded access to thermal capabilities across new applications and price points, growing from initial market niches into broader OEM module offerings.

The right supplier category depends entirely on your program requirements. High-volume defense contracts may benefit from established prime contractor relationships, while custom product development often aligns better with specialized manufacturers offering deeper engineering collaboration and production flexibility.

Why Does Supply Chain Diversification Matter for Thermal Imaging?

Smart procurement strategy increasingly emphasizes supplier diversification across critical components. For thermal imaging specifically, several factors drive this approach.

Supply chain resilience represents the primary motivation. Procurement professionals recognize that multi-source strategies provide production continuity protection and negotiating flexibility. Building relationships with multiple thermal camera manufacturers reduces vulnerability during industry-wide capacity constraints or disruption events.

Access to specialized capabilities also factors into diversification decisions. Different manufacturers bring distinct strengths—some excel in high-volume production, others in rapid custom engineering, and still others in specific technology niches like proprietary infrared glass materials. Maintaining multiple supplier relationships ensures OEMs can match each project's requirements with optimal manufacturing partners.

Geographic considerations add another dimension. Domestic manufacturing presence, compliance certifications, and regional support capabilities vary across thermal camera manufacturers. Diversified sourcing allows OEMs to align supplier selection with specific program requirements.

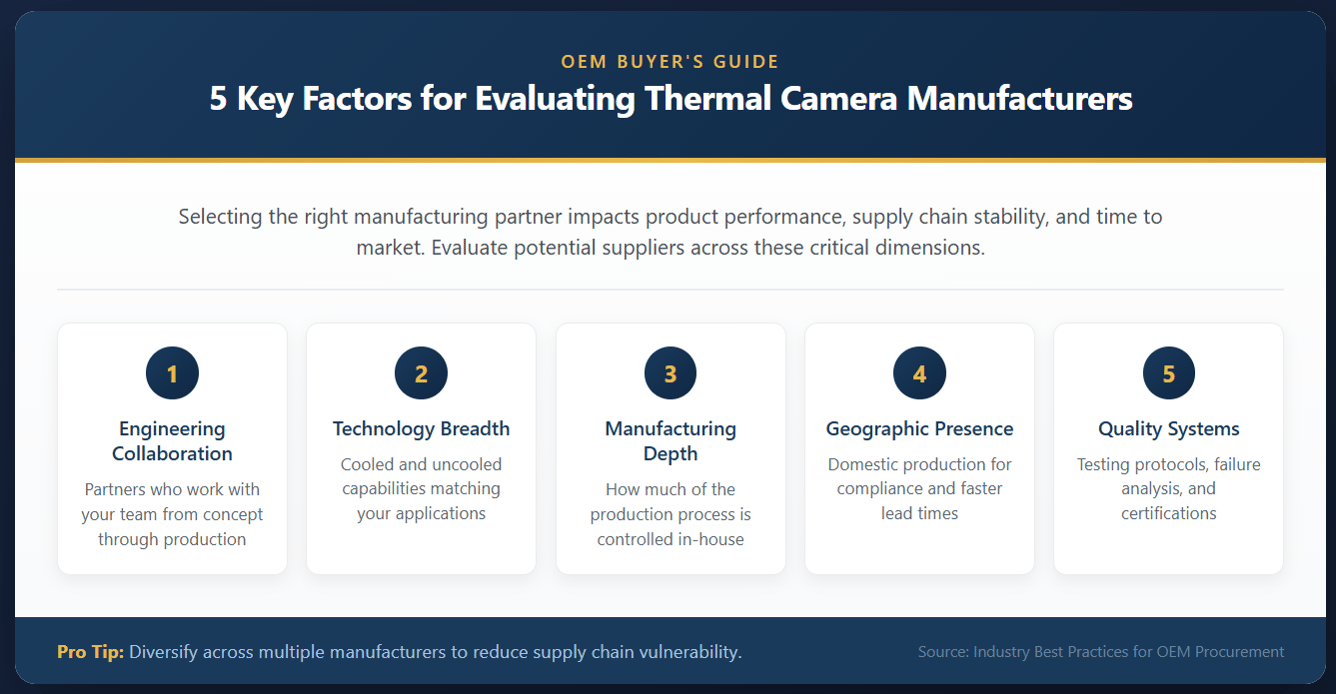

Key Factors When Evaluating Thermal Camera Manufacturers

Successful supplier selection requires systematic evaluation across multiple dimensions. Consider these essential criteria when assessing potential thermal camera manufacturers:

Integration Support Depth. Does the manufacturer offer engineering collaboration throughout your development cycle, or simply fulfill purchase orders? The distinction between supplier and partner becomes apparent during challenging integration scenarios.

Cooled and Uncooled Capabilities. Your application requirements should align with the manufacturer's technology strengths. Some thermal camera manufacturers excel in uncooled systems optimized for SWaP-constrained applications, while others focus on cooled solutions for maximum sensitivity.

Geographic Manufacturing Presence. For defense applications especially, domestic manufacturing and supply chain compliance matter. Understanding where components originate and where assembly occurs affects both security considerations and trade compliance.

Quality Control Processes. In-house manufacturing with comprehensive quality systems differs substantially from assembly operations relying on third-party components. Ask about testing protocols, failure analysis capabilities, and quality certifications.

Scalability and Responsiveness. Can the manufacturer support both prototype quantities and production volumes? How quickly can they respond to design changes or urgent delivery requirements?

How Vertical Integration Benefits System Integrators

The most capable thermal camera manufacturers control their processes from raw materials through finished systems. This vertical integration delivers several concrete advantages for OEMs and system integrators evaluating partnership options.

Quality consistency improves when a single organization controls detector fabrication, lens production, assembly, and testing. Handoff points between different suppliers introduce variability and potential miscommunication about requirements. Vertically integrated manufacturers eliminate these transition risks.

Customization becomes more practical when all capabilities exist under one roof. Need a modified coating specification? Different housing dimensions? Application-specific firmware? Vertically integrated thermal camera manufacturers can accommodate these requests without coordinating across multiple external suppliers.

Supply chain resilience strengthens considerably with vertical integration. When U.S. thermal camera makers produce their own critical components domestically, they insulate OEM customers from international supply disruptions and geopolitical material access concerns. This independence has become increasingly valuable in recent years.

Frequently Asked Questions

What distinguishes thermal camera manufacturers that serve OEMs from those targeting end users? OEM-focused thermal camera manufacturers emphasize integration support, customization capabilities, and supply chain transparency over retail features like user interfaces or accessories. They understand that their cameras become components within larger systems, requiring engineering collaboration and production scalability that consumer-oriented manufacturers may not provide.

Why should OEMs consider multiple U.S. thermal camera makers rather than single-sourcing? Diversifying across thermal camera manufacturers reduces supply chain risk, provides pricing leverage, and ensures access to different technological approaches. Single-source strategies can create vulnerability during production disruptions or when primary suppliers face capacity constraints.

How important is vertical integration when selecting thermal camera manufacturers? Vertical integration significantly impacts quality consistency, customization flexibility, and supply chain resilience. Manufacturers controlling everything from raw materials to finished systems can respond faster to custom requirements and maintain more consistent quality than those relying on external component suppliers.

Partner with Confidence

Finding thermal camera manufacturers who understand OEM requirements and deliver genuine partnership value requires careful evaluation. The market offers options beyond dominant players, with specialized manufacturers providing compelling combinations of technology capability, customization flexibility, and supply chain security.

LightPath Technologies brings four decades of optical and thermal imaging expertise to OEMs and system integrators seeking premium solutions with genuine engineering partnership. From proprietary BlackDiamond™ materials to complete camera systems, LightPath delivers the vertical integration and collaborative approach that sophisticated programs demand. Connect with the LightPath team to explore how the right manufacturing partner can strengthen your thermal imaging capabilities.