LWIR Lens Design: Overcoming Critical Challenges

Key Takeaways

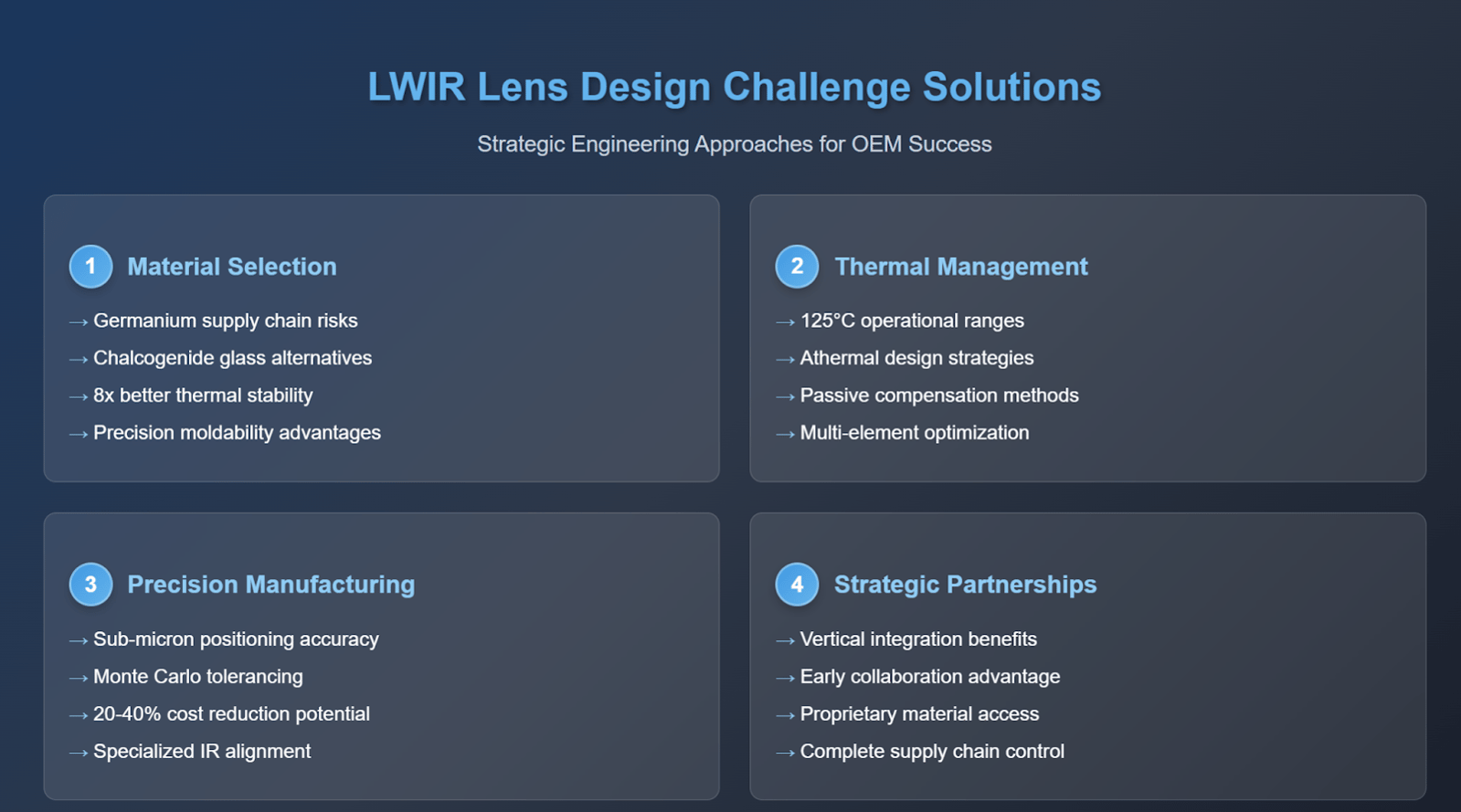

Advanced LWIR lens design requires strategic engineering approaches that balance performance, cost, and manufacturing feasibility for successful OEM integration.

- Material selection challenges demand innovative alternatives to traditional germanium-based solutions to ensure supply chain stability and cost control

- Thermal management complexity requires comprehensive athermal design strategies that maintain optical performance across demanding temperature ranges

- Precision manufacturing constraints necessitate advanced tolerancing methodologies and optical alignment techniques to achieve system-level performance requirements

- Custom engineering partnerships provide the most effective path to overcoming design challenges while meeting specific integration requirements

OEMs developing thermal imaging systems must prioritize vertically integrated manufacturing partners who understand both optical physics and real-world deployment challenges.

Long-wave infrared (LWIR) systems operating in the 8-14 micrometer spectral range represent some of the most demanding optical engineering challenges in modern thermal imaging applications. For OEMs developing everything from defense surveillance platforms to industrial monitoring systems, LWIR lens design decisions directly impact system performance, manufacturing costs, and market competitiveness.

The complexity of LWIR lens design extends far beyond traditional visible-light optics, requiring specialized approaches to material selection, thermal management, and precision manufacturing. According to recent market analysis from DataIntelo, the global LWIR transmitting glass lens market is projected to reach $2.5 billion by 2032, driven primarily by defense and industrial applications requiring increasingly sophisticated thermal imaging capabilities.

What Makes LWIR Lens Design More Complex Than Traditional Optics?

The fundamental physics of LWIR imaging creates unique engineering constraints that distinguish these systems from conventional optical designs. Unlike visible-light applications where glass materials offer numerous options, LWIR wavelengths severely limit material choices to a handful of specialized compounds, each presenting distinct advantages and limitations.

Material Constraint Impacts on OEM Development

The limited material palette forces engineers to work within narrow design parameters while still achieving demanding performance specifications. Germanium, traditionally the gold standard for LWIR applications, delivers exceptional optical properties but introduces significant supply chain risks and thermal stability challenges that can impact entire product development timelines.

Thermal Lens Manufacturing Complexities

The relationship between thermal expansion and optical performance becomes critical when systems must operate across temperature ranges spanning 125°C or more. Unlike visible-light systems where thermal effects might cause minor focus shifts, LWIR systems experiencing thermal drift can lose target acquisition capability entirely.

Precision Tolerancing Requirements

LWIR lens elements demand sub-micron positioning accuracy while accommodating thermal expansion effects that can shift components by significant amounts across operational temperature ranges. This creates a manufacturing paradox requiring both extreme precision and thermal accommodation.

Why Is Material Selection Critical for LWIR Lens Success?

Traditional germanium-based lens designs dominate LWIR applications due to the material's exceptional refractive index properties in the 8-14 micrometer range. However, reliance on germanium introduces several critical challenges that affect system development and long-term viability.

Germanium Dependency and Supply Chain Risks

Germanium scarcity creates fundamental business risks for OEMs developing LWIR-based products. The material's high cost and limited global supply can impact project budgets and delivery schedules, particularly for systems requiring larger lens diameters or complex multi-element designs.

Beyond supply considerations, germanium's thermal properties introduce significant engineering challenges. The material exhibits substantial refractive index changes with temperature, requiring compensatory design approaches that add mechanical complexity and increase system costs.

Alternative Materials and Design Trade-offs

Chalcogenide glass materials, particularly advanced formulations designed for LWIR applications, offer compelling alternatives to germanium-based designs. These materials can be precision molded into complex aspheric surfaces, reducing manufacturing costs while providing thermal stability advantages.

According to analysis from Markets and Markets, chalcogenide materials are gaining significant traction in industrial applications where cost-effectiveness and moldability advantages outweigh the optical performance trade-offs compared to crystalline germanium.

Zinc selenide (ZnSe) represents another alternative offering improved thermal stability compared to germanium. While ZnSe requires different manufacturing approaches, its superior thermal coefficient of refractive index makes it particularly attractive for systems operating in extreme temperature environments.

|

Material |

Thermal Coefficient (dn/dT) |

Moldability |

Relative Cost |

Supply Stability |

|

Germanium |

396 × 10⁻⁶/°C |

Limited |

High |

Constrained |

|

Chalcogenide Glass |

~50 × 10⁻⁶/°C |

Excellent |

Moderate |

Good |

|

Zinc Selenide |

61 × 10⁻⁶/°C |

Limited |

Moderate |

Good |

Thermal Management and Athermal Design Strategies

Thermal management represents perhaps the most critical aspect of successful LWIR lens design. Systems must maintain optical performance across temperature ranges that would render conventional optical systems inoperative, requiring sophisticated engineering approaches that balance optical performance with mechanical complexity.

Understanding Thermal Defocus Mechanisms

Multiple factors contribute simultaneously to thermal defocus in LWIR systems: lens material refractive index changes, mechanical housing expansion, and detector assembly thermal shifts. Each component's thermal response must be carefully characterized and accommodated in the overall system design.

Standard aluminum housings can experience significant dimensional changes with temperature variations. For many LWIR lens design applications, these expansion effects can equal or exceed the system's depth of focus, making thermal compensation essential rather than optional.

Passive Athermal Design Approaches

Passive athermal design techniques eliminate the need for active focus mechanisms by using material properties and mechanical design to compensate for thermal effects. These approaches typically involve careful material selection for housing components and precise engineering of thermal expansion coefficients.

Optical athermalization involves selecting lens materials with offsetting thermal coefficients, allowing positive and negative thermal effects to cancel across the operational temperature range. This approach requires sophisticated optical design capabilities and access to multiple material options.

Mechanical athermalization uses differential thermal expansion between housing components to maintain lens positioning across temperature changes. While mechanically complex, this approach can accommodate wider temperature ranges than purely optical solutions.

Advanced Compensation Techniques

Modern LWIR systems increasingly employ hybrid approaches combining optical design optimization with sophisticated mechanical compensation. These systems might use materials with opposing thermal coefficients in multi-element designs while incorporating mechanical spacing adjustments to fine-tune thermal performance.

Precision Manufacturing and Optical Alignment Complexities

The transition from LWIR lens design to manufacturable products introduces additional layers of complexity that significantly impact both performance and cost. Manufacturing tolerances that might be acceptable in visible-light applications become critical performance limiters in LWIR systems.

Tolerancing Strategies for LWIR Applications

Traditional worst-case tolerance analysis often results in unnecessarily expensive manufacturing requirements that don't reflect real-world production capabilities or performance needs. LWIR systems require more sophisticated statistical approaches that account for the interaction between multiple tolerance sources.

Advanced Monte Carlo simulation techniques provide more realistic predictions of manufactured system performance by modeling the statistical distribution of manufacturing errors rather than assuming worst-case scenarios. This approach typically reduces manufacturing costs while maintaining performance requirements.

Research from SPIE proceedings demonstrates that statistical tolerancing approaches can reduce manufacturing costs by 20-40% compared to traditional worst-case methods while actually improving prediction accuracy of final system performance.

Optical Alignment Methodologies

The infrared wavelengths used in LWIR systems require specialized test equipment and procedures that differ fundamentally from visible-light alignment techniques. Additionally, thermal effects that might be negligible during room-temperature alignment can become performance-limiting factors in operational environments.

Advanced manufacturers employ thermal cycling during optical alignment procedures, using specialized thermal chambers and infrared test equipment to verify performance across operational temperature ranges before final assembly completion.

Successful optical solutions require comprehensive understanding of both material properties and manufacturing constraints to achieve optimal system performance.

Lens Coatings and Surface Treatment Considerations

Anti-reflection lens coatings for LWIR applications require specialized materials and deposition techniques optimized for longer wavelengths. These coatings must maintain performance across wide temperature ranges while providing durability in demanding environmental conditions.

Traditional visible-light coating materials often become absorptive in LWIR wavelengths, requiring alternative materials with different thermal expansion properties. Coating stress and thermal cycling effects can significantly impact lens performance if not properly managed during the design phase.

3 Common Design Pitfalls and How Can You Avoid Them

Successful LWIR lens design requires understanding not just what works, but what commonly fails and why. Many OEM development programs encounter predictable challenges that experienced optical engineering teams can help avoid through early planning and strategic design approaches.

-

Material Selection Mistakes

Overreliance on single-material solutions represents one of the most common early-stage design errors. While germanium might provide optimal optical properties, systems designed around single-material approaches often encounter manufacturing or cost challenges that could have been avoided through hybrid approaches.

Insufficient thermal characterization of materials across operational temperature ranges leads to systems that perform well in laboratory conditions but fail in real-world deployments. This challenge particularly affects systems designed for harsh environmental conditions where thermal cycling effects become critical.

-

Mechanical Design Oversights

Inadequate stress analysis during lens mounting design can lead to thermally-induced optical distortions that degrade system performance. LWIR lens materials often exhibit different mechanical properties compared to conventional glass, requiring specialized mounting approaches.

Poor thermal interface design between optical components and mechanical housings can create thermal gradients that affect optical performance. These effects often don't appear during initial testing but become apparent during extended operational use.

-

Manufacturing Process Misunderstandings

Underestimating alignment complexity leads to manufacturing schedules and cost estimates that don't reflect the specialized equipment and procedures required for LWIR system assembly. Early engagement with manufacturing partners helps establish realistic timelines and cost expectations.

Insufficient environmental testing during development can result in systems that meet initial specifications but fail during environmental qualification testing. LWIR systems often require more extensive thermal cycling and vibration testing compared to conventional optical systems.

What Makes Partnership-Based Development Most Effective for LWIR Systems?

Successful LWIR lens development requires strategic thinking that extends beyond traditional optical design considerations. OEMs must balance performance requirements with manufacturing realities while maintaining cost targets and delivery schedules.

Early Engineering Collaboration Benefits

Early engineering collaboration between OEM design teams and specialized optical manufacturers enables design decisions that optimize both performance and manufacturability from project inception. This collaborative approach typically reduces both development time and total system cost compared to traditional sequential development processes.

Integrated material expertise becomes particularly valuable in LWIR applications where material properties significantly impact both optical performance and manufacturing approaches. Partners with proprietary material capabilities can offer design solutions not available through standard commercial channels.

Evaluating LWIR Lens Development Partners

Manufacturing capability assessment should focus not just on optical fabrication but on the complete supply chain including specialized materials, environmental testing, and quality systems appropriate for the target application environment.

Design heritage and application experience in similar applications provides valuable insight into potential challenges and proven solution approaches. Partners with extensive LWIR experience can help avoid common pitfalls while suggesting optimization opportunities.

When Custom Engineering Provides the Best Value

Complex environmental requirements often necessitate custom solutions that balance multiple competing constraints. Standard catalog approaches rarely provide optimal solutions for demanding defense or industrial applications requiring extended temperature ranges or harsh environmental capability.

System integration considerations frequently drive custom engineering requirements when LWIR lens assemblies must interface with existing mechanical designs or provide specific electrical or mechanical interfaces beyond standard optical mounts.

Advanced thermal imaging lens assemblies demonstrate how comprehensive engineering approaches can address multiple design challenges simultaneously.

What Innovations Are Driving LWIR Lens Design Advancement?

The LWIR lens design landscape continues evolving as new materials, manufacturing techniques, and application requirements drive innovation throughout the industry. Understanding these trends helps OEMs make development decisions that remain competitive over product lifecycles.

Emerging Material Technologies

Advanced chalcogenide glass formulations continue expanding the available design space for LWIR lens design applications. These materials offer improved thermal stability and moldability while maintaining optical performance suitable for demanding applications.

Recent developments in proprietary glass formulations enable optical designs previously constrained by traditional material limitations. These advances particularly benefit compact system designs where conventional approaches might require larger or more complex lens assemblies.

Manufacturing Innovation Impacts

Precision molding capabilities for LWIR materials continue improving, enabling more complex aspheric designs while reducing thermal lens manufacturing costs. These capabilities particularly benefit high-volume applications where traditional grinding and polishing approaches become cost-prohibitive.

Advanced coating technologies designed specifically for LWIR applications provide improved environmental durability while maintaining optical performance across wider spectral ranges. These developments enable more robust systems suitable for extended field deployment.

How Do You Select the Right Precision Tolerancing Approach for LWIR Applications?

Understanding the relationship between manufacturing precision and optical performance becomes critical for cost-effective LWIR system development. Different applications require different balance points between precision and cost.

Statistical vs. Deterministic Tolerancing

Monte Carlo simulation approaches provide more realistic performance predictions by modeling the statistical distribution of manufacturing errors rather than assuming worst-case scenarios. This methodology typically allows relaxed individual component tolerances while maintaining system performance requirements.

Deterministic approaches may still be appropriate for critical applications where absolute performance guarantees outweigh cost considerations. These approaches typically result in higher manufacturing costs but provide certainty of performance across all manufactured units.

Environmental Testing Integration

Thermal cycling protocols during manufacturing validation help identify potential performance issues before field deployment. These tests become particularly important for systems operating across wide temperature ranges or in harsh environmental conditions.

Vibration and shock testing validates both mechanical design adequacy and optical alignment stability under operational stress conditions. LWIR systems often require more extensive environmental testing compared to conventional optical systems due to their precision tolerancing requirements.

Frequently Asked Questions

What makes LWIR lens design more challenging than visible-light optics? LWIR lens design faces severe material limitations, extreme thermal sensitivity, and wavelength-specific manufacturing requirements that don't exist in visible-light applications. The 8-14 micrometer wavelength range requires specialized materials like germanium or chalcogenide glass, each presenting unique engineering challenges for thermal stability and manufacturing precision.

How significant are thermal effects in LWIR lens performance? Thermal effects in LWIR systems can completely eliminate optical performance if not properly managed. Temperature changes across operational ranges can shift mechanical components significantly, often exceeding the system's depth of focus. Successful designs require comprehensive athermal engineering approaches that maintain performance across operational temperature ranges.

What are the main advantages of chalcogenide glass over germanium for LWIR applications? Chalcogenide glass offers superior thermal stability, excellent moldability for complex aspheric surfaces, improved supply chain stability, and generally lower material costs. While optical performance may be slightly reduced compared to germanium, these advantages often outweigh the trade-offs for many applications.

How do manufacturers ensure LWIR lens alignment accuracy during assembly? Advanced LWIR manufacturers use specialized infrared test equipment, thermal cycling procedures, and statistical Monte Carlo tolerancing approaches rather than traditional worst-case methods. This typically includes alignment verification across operational temperature ranges using thermal chambers and IR-specific metrology equipment to ensure performance stability.

When should OEMs consider custom LWIR lens development versus catalog solutions? Custom development becomes necessary when systems require specific environmental performance (extended temperature ranges, shock/vibration resistance), unique mechanical interfaces, specialized coatings, or performance optimization for particular applications. Most demanding defense and industrial applications benefit from custom engineering approaches that optimize the complete system rather than individual components.

Building Excellence Through Strategic Partnership

The complexity of modern LWIR lens design challenges makes partnership selection one of the most critical decisions facing OEM development teams. Success requires more than optical expertise; it demands understanding of system integration, environmental requirements, and manufacturing realities that span multiple engineering disciplines.

Leading thermal imaging OEMs increasingly recognize that vertically integrated manufacturing partners provide the most effective approach to complex LWIR design challenges. When materials science, optical design, precision manufacturing, and environmental testing capabilities exist within a single organization, the iterative optimization required for successful LWIR systems becomes far more efficient and cost-effective.

Organizations developing comprehensive thermal imaging solutions benefit significantly from partnerships that combine advanced material capabilities with comprehensive manufacturing expertise. This integration enables design optimization approaches that balance optical performance with manufacturing realities from project inception.

For over four decades, LightPath Technologies has pioneered advanced optical solutions that give aerospace, defense, and industrial clients the competitive advantages they need. Our proprietary Black Diamond™ chalcogenide glass technology, combined with complete vertical integration from materials to finished camera systems, provides the comprehensive capabilities required for successful LWIR lens development in today's demanding applications. Contact our engineering team to discuss your specific LWIR design challenges.