Uncooled Vox Microbolometer FPA Based

High Temperature Imaging in Mid Infrared

Filters out Flames and Smoke

Overview

- Uncooled Infrared Thermal imaging core for imaging of high temperatures

- Applications include Process control, Furnace and Boiler Inspection and more

- Mid wave infrared imaging at wavelengths around 3-4µm

- Image not obstructed by any flames or burning inside the furnace

- Calibrated for the exact optics that will be used with it

Technology

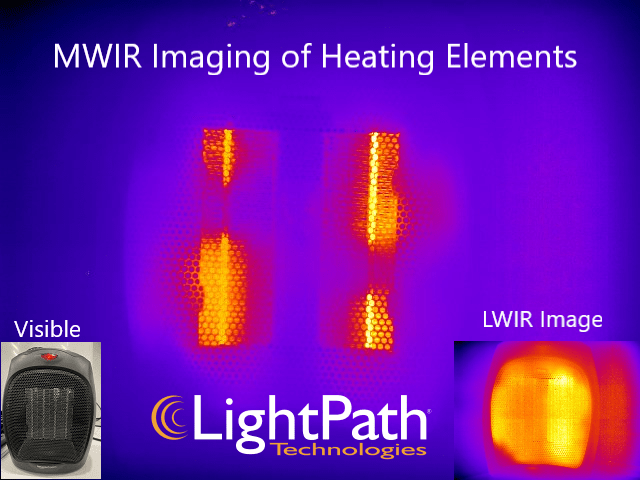

Per Planck’s law, the peak wavelength a blackbody emits is inversely proportional to its temperature. Since most hot objects emit blackbody (or graybody, an approximation of blackbody) radiation, the higher the temperature of the object, the shorter the wavelength it emits. As a result, warm objects below about 400°C emit mostly long wave radiation. And there for objects such as humans, landscape and such are best detected using long wave infrared (LWIR), operating at 8-12µm.

Hot objects, with temperatures higher than that, emit blackbody radiation at shorter wavelengths. And as such, a Kiln operating at 1000°C for example, will emit blackbody radiation peaking around 2 µm. see Graph to the right. Accordingly, to image temperatures that we typically see inside furnaces, boilers and Kilns, a camera operating in the shorter wavelengths of 2-5µm is needed.

The technology behind LightPath’s furnace imaging core is based on our Mantis™ broadband uncooled imaging core, as well as our matching broadband optics. Leveraging the unique imaging capability of the Mantis, and proprietary technology for operating the imaging core at such wavelengths, our furnace imaging cores can be configured to image the high temperatures seen inside furnaces.

Product

LightPath’s furnace imaging core is available with different options and features.

- Interface. Standard interface of CameraLink. GigE, USB Vision and other interfaces are optional.

- Optics. LightPath offers standard optics for use with the camera core, as well as the option to calibrate the imaging core with customer provided optics, such as the air cooled relay tube shown to the left

- Options. Option for additional calibrations to switch mode to long wave thermal imaging (LWIR) for imaging of lower temperatures

Contact