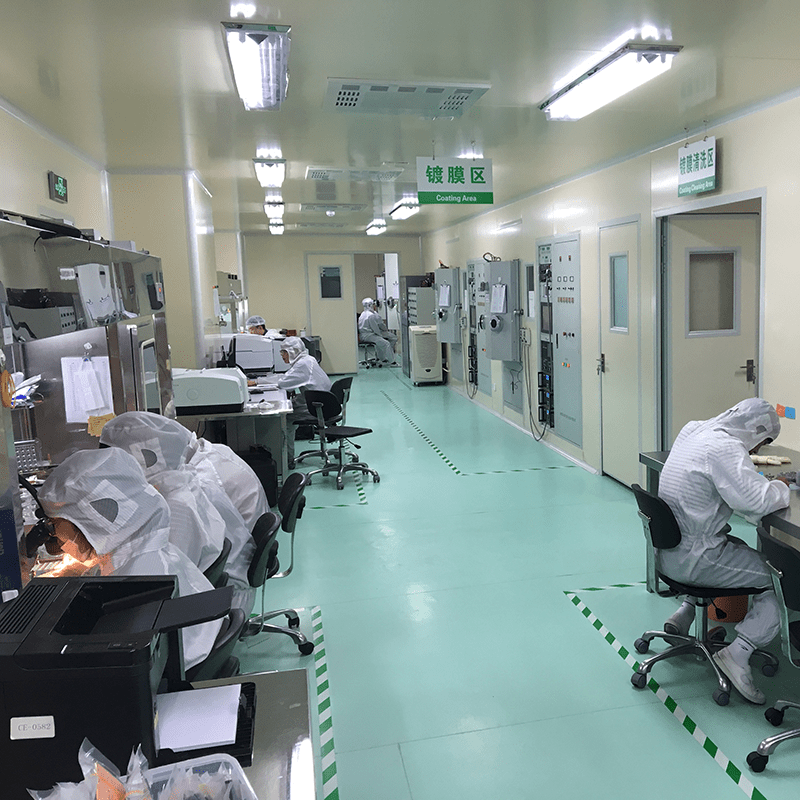

Coatings available in our three facilities, China, Europe and the US

Anti Reflective, Protective DLC, Beam Splitters and Spectral Filters

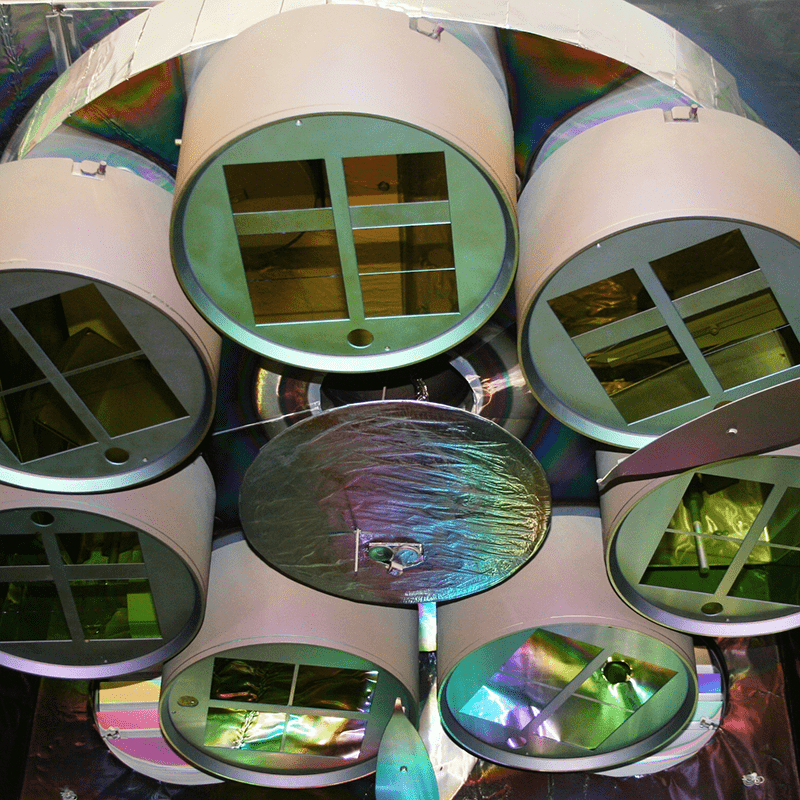

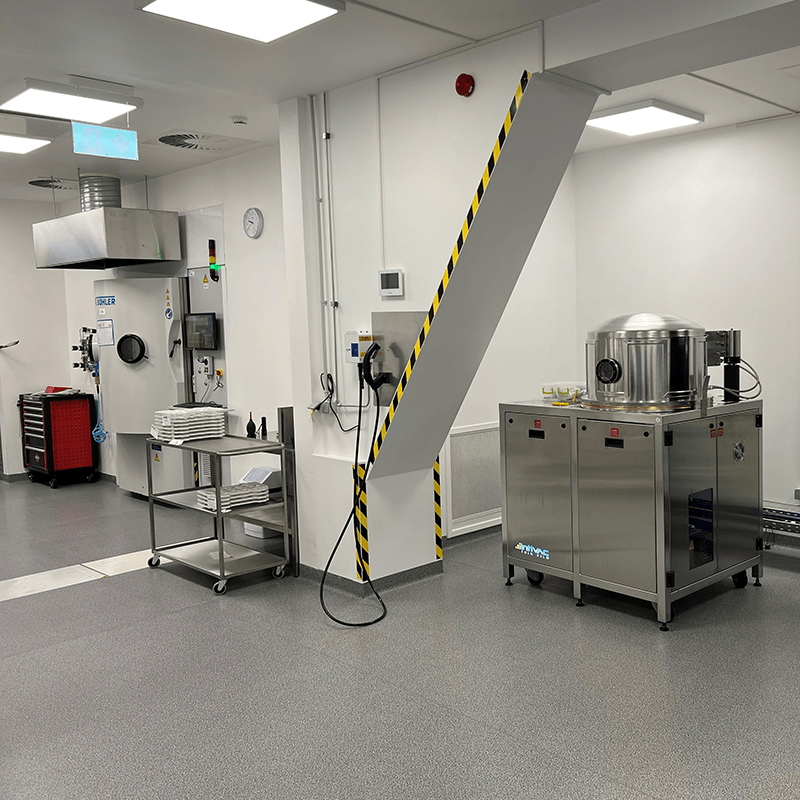

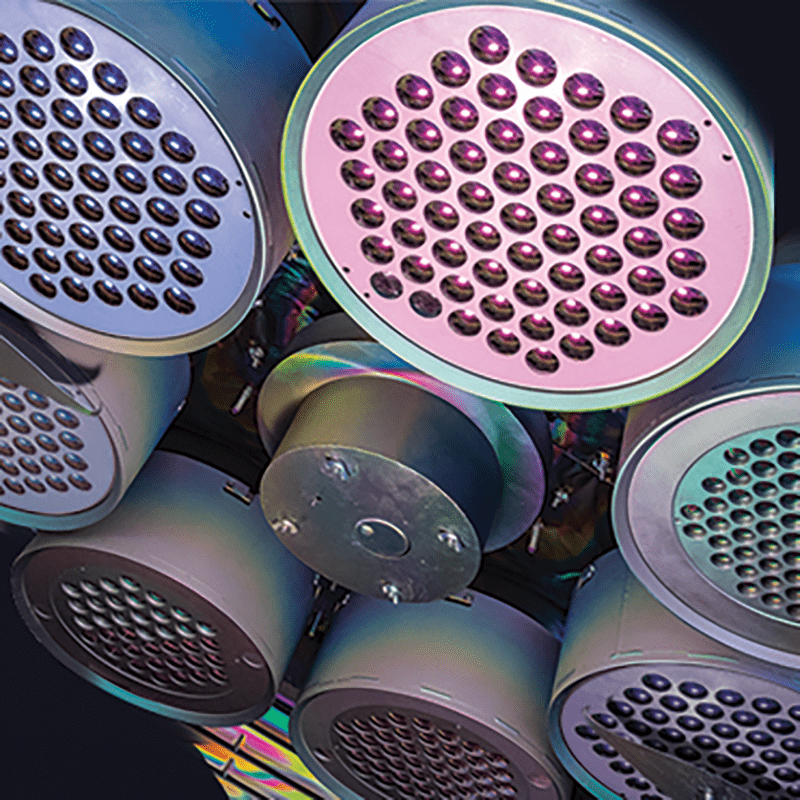

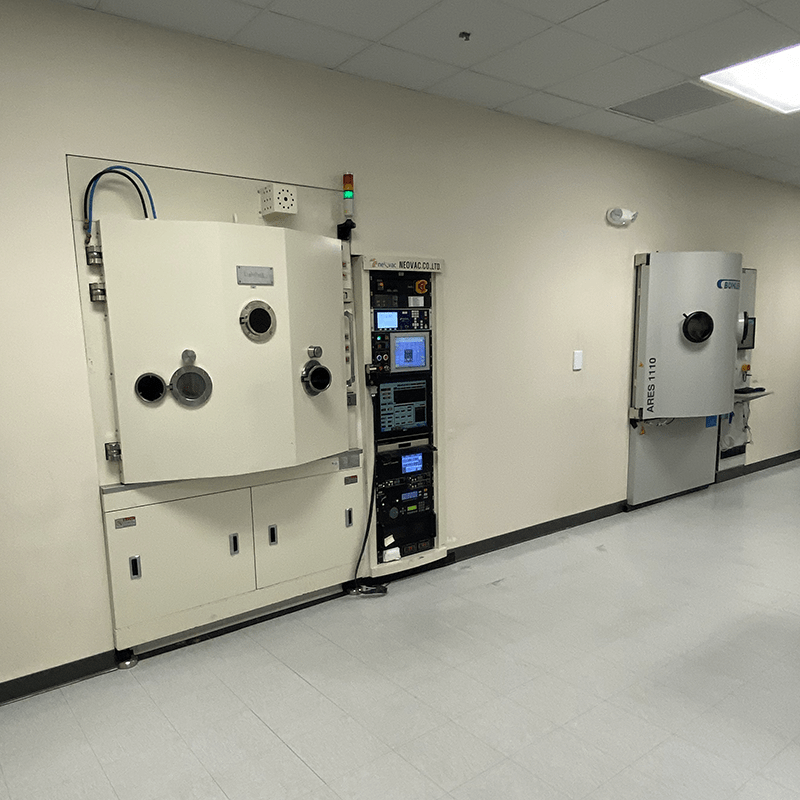

Over a dozen PVD and CVD coating chambers

Overview

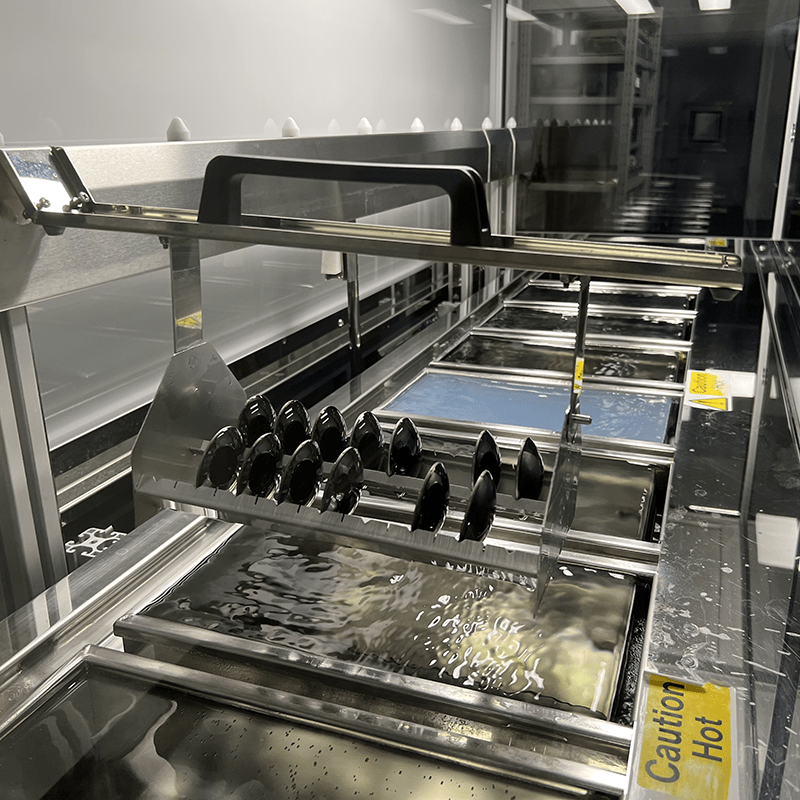

From Ultraviolet and Visible, to Near, Mid and Long Wave Infrared, LightPath offers a broad variety of deposition technologies allowing us to create custom coating solutions for the most demanding applications. LightPath utilizes multiple coating processes and technologies including thermal resistance and electron beam Physical Vapor Deposition (PVD), Ion Assisted Deposition (IAD), Chemical Vapor Deposition (CVD), and Plasma Enhanced Chemical Vapor Deposition (PECVD) to cover a wide range of design solutions over many different types of substrates.

We are experts in optical thin film designs, with extensive experience designing virtually every type of thin film coating (antireflection, high reflection, partial reflection, bandpass, protective, etc.). We provide broad expertise with applications in the Visible, SWIR, MWIR, LWIR, and multiband hyperspectral regions as well as protective Diamond Like Carbon (DLC) anti reflecting coatings. LightPath is vertically integrated in all three of its global facilities including in-house coating capabilities in each manufacturing location.

Our Standard Coatings

Visible and Near Infrared (NIR) Coatings

|

Anti Reflective Coatings |

|

|

Spectral Range |

Materials |

|

350-500nm |

D-LaK6, L-LAL12 |

|

400-600nm |

D-ZK3, D-ZLaF52LA, D-LaK6, L-LAL12 |

|

600-1050nm |

D-ZK3, D-ZLaF52LA |

|

700-900nm |

D-ZK3, D-ZLaF52LA |

Short Wave Infrared – SWIR

|

Anti Reflective Coatings |

|

|

Spectral Range |

Materials |

|

1.5-5um |

BD6, ZnSe, ZnS, Si, BD2, AMTIR-1, BaF2, CdTe, CaF2 |

|

1.5-3um |

BD2 |

|

1.5-1.8um |

Si, S-TIM2, ZnS, ZnSe |

|

1.8-3um |

BD2 |

|

1.050-1.600um |

DZK3, DZlaF52LA, ECO550 |

|

1.300-1.700um |

DZK3, DZlaF52LA, ECO550 |

|

Beam Splitter Coatings |

|

|

Spectral Range |

Materials |

|

1.5-5um @ 45 Deg |

CaF2 |

|

2-5um @ 45 Deg |

Sapphire |

Mid Wave Infrared – MWIR

|

Anti Reflective Coatings |

|

|

Spectral Range |

Materials |

|

3-5um |

Ge, BD6, BD2, Si, ZnS, ZnSe, IRG-202, GASIR-1, Sapphire, GaAs |

|

3-5µm HDAR/HEAR |

Ge, Si |

|

2.0-6.0um |

Si |

|

1.064µm & 3-5µm |

BD6 |

|

Protective DLC |

|

|

Spectral Range |

Materials |

|

3-5um |

Ge, Si, BD6, BD2 |

|

Beamsplitter Coatings |

|

|

Spectral Range |

Materials |

|

3-5µm @ 45deg |

Ge, Si |

|

2-8um @ 45 Deg |

CaF2 |

Long Wave Infrared (LWIR)

|

Anti Reflective Coatings |

|

|

Spectral Range |

Materials |

|

5-11um |

Ge, ZnS, ZnSe |

|

8-12um |

Ge, GaAs, ZnS, ZnSe, BD2, BD6, AMTIR-1, IRG-202, IRG-24, IG4, GASIR-1 |

|

8-12µm HDAR/HEAR |

Ge, ZnSe |

|

7-14um |

BD6 |

|

7-10um |

Ge |

|

7.5-13um |

CdTe |

|

14-16um |

Ge |

|

Protective DLC |

|

|

Spectral Range |

Materials |

|

8-12um |

Ge, BD2, BD6 |

|

Beamsplitter Coatings |

|

|

Spectral Range |

Materials |

|

8-12um @ 45 Deg |

Ge |

|

7-14um @ 45 deg |

ZnSe |

MultiSpectral Coatings

|

Anti Reflective Coatings |

|

|

Spectral Range |

Materials |

|

2-13um |

Ge, ZnS, ZnSe, BD6, BD2 |

|

2-14um |

ZnSe |

|

3-12um |

ZnSe |

|

5-8um |

Ge, BD2 |

|

1.5-5µm & 8-14µm |

ZnS |

|

6.5-6.9um |

ZnSe |

|

1.0-12um |

ZnSe |

|

0.633µm & 1-12µm |

ZnSe |

|

1.5-5µm & 8-14µm |

ZnS |

|

1.064µm & 3-5µm |

BD6 |

|

Beam Splitter |

|

|

Spectral Range |

Materials |

|

2-8um @ 45 Deg |

CaF2 (50/50) |

Laser Line Coatings

|

Anti Reflective Coatings |

|

|

Spectral Range |

Materials |

|

3.39um |

Ge, ZnSe |

|

0.633µm & 3.39µm |

ZnSe |

|

0.633µm & 3.39µm & 10.6µm |

ZnSe |

|

1.064µm & 1.570µm |

ZnSe |

|

1.95-2.15µm & 3.9-4.1µm & 4.5-4.7µm |

ZnSe |

|

0.633µm & 1-12µm |

ZnSe |

|

1.064µm & 3-5µm |

BD6 |

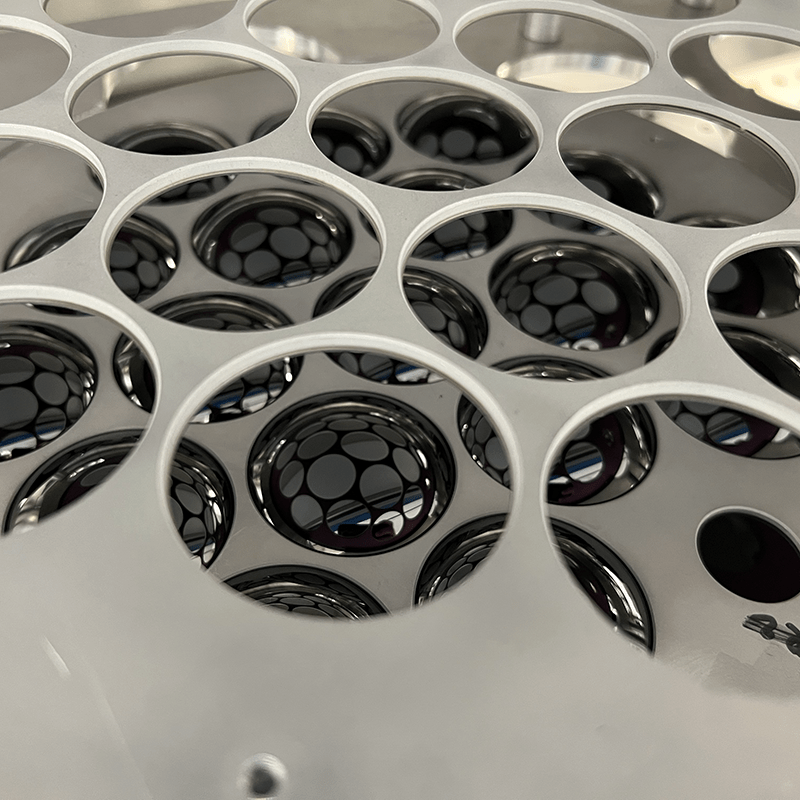

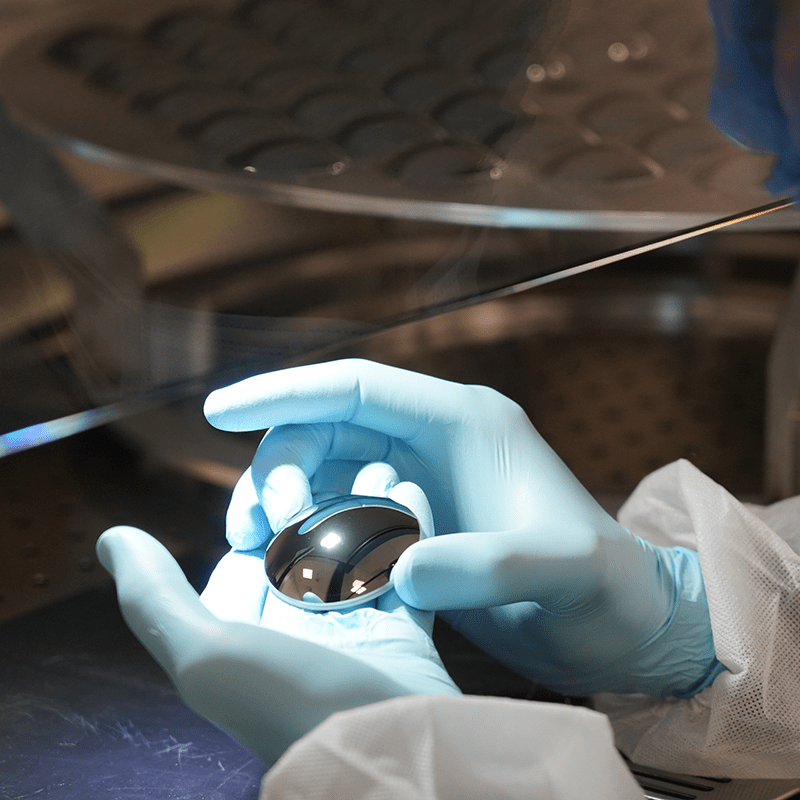

DLC Coating on Chalcogenide

Diamond Like Carbon (DLC) coating is in use in many industries, including optics, due to its high hardness and low friction. While DLC had been in use with Germanium and Silicon optics for a while, it is only recently that it had been successfully applied to amorphous materials such as Chalcogenide Glass. Through our expertise in the Chalcogenide materials, fabrication process and coatings, Lightpath had been bale to design DLC coatings that can be applied to our Chalcogenide lenses and windows. Our DLC coatings, applied using a highly customized CVD coating chamber, have passed all MIL spec qualification requirements, including full salt solubility for 24 hours.