Freeform Optics

High volume manufacturing of Glass Freeform Optics Using our Proprietary Molding Technology

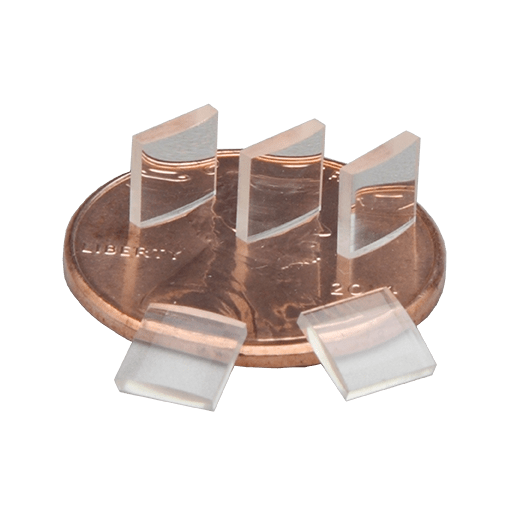

Sizes from sub millimeter to 52mm

Standard and Specialty Coatings Available, including AR, HDAR, HEAR and DLC

Overview

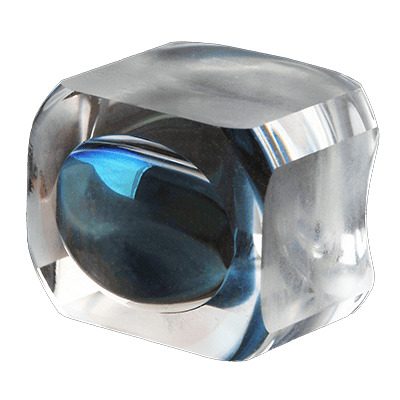

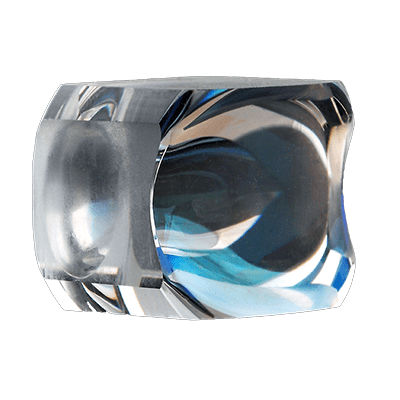

Freeform optics, as their name implies, are free from any constraints of symmetry in their form and shape. Freeform systems provide better optical performance than traditional designs which are key to applications such as augmented reality/virtual reality (AR/VR), automotive LIDAR and military optical systems and medical technologies.

As an emerging technology for some time, freeforms have been limited by manufacturing technology until today. Recent advancements in CNC machining now allow the production of small quantities of freeform optics, but do not provide an adequate solution for volume production.

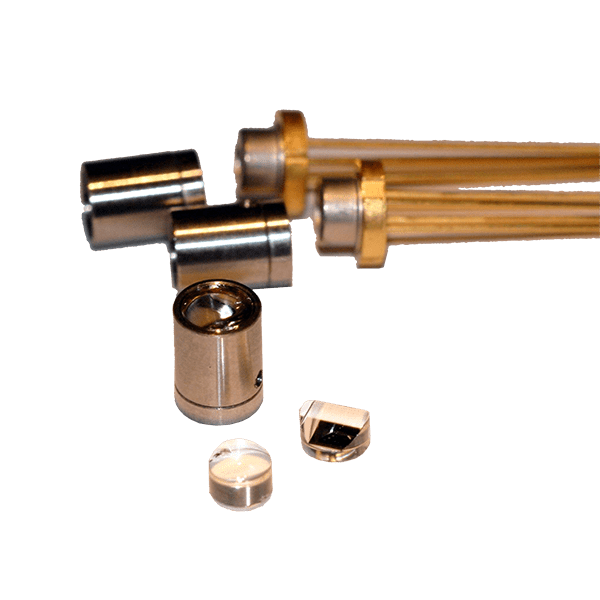

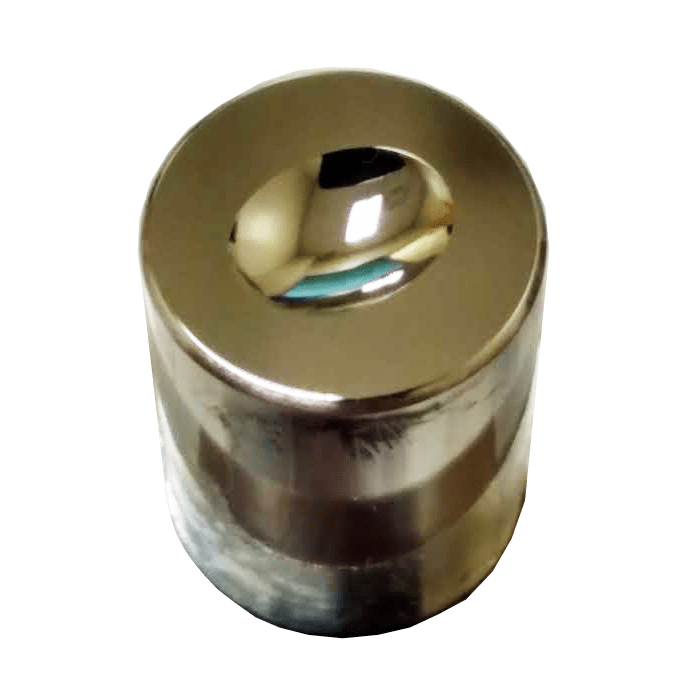

At LightPath Technologies, we’ve taken decades of experience in precision molding of lenses and extended this technology to begin producing high volume, precision molded freeform optics.

Since our early days as Geltech Corporation over 25 years ago, LightPath has been the leader of precision molded optics, continuously innovating and pushing the limits of precision glass molding. Today, leveraging our positioning in three continents, our capacity to produce millions of molded lenses can be further broadened to support high volume applications with precision molded freeform optics.

Typical Tolerances

| Parameter | Specification |

|---|---|

| Size |

Up to 52 mm |

| Material |

H-FK61, D-ZK3, D-LaK6, D-ZLaF52LA, Infrared Chalcogenide Glass |

| Diameter Tolerance (mm) |

+/-0.015 |

| Clear Aperture |

90% of outer diameter |

| Center Thickness Tolerance (mm) |

+/-0.030 |

| Surface Error P-V (nm) |

<1000 |

| Surface Error RMS (nm) |

<300 |

| Surface Roughness (nm) |

<3 |

| Scratch Dig |

40-20 |

| AR Coating |

Standard multilayer broadband coatings and custom coatings available |

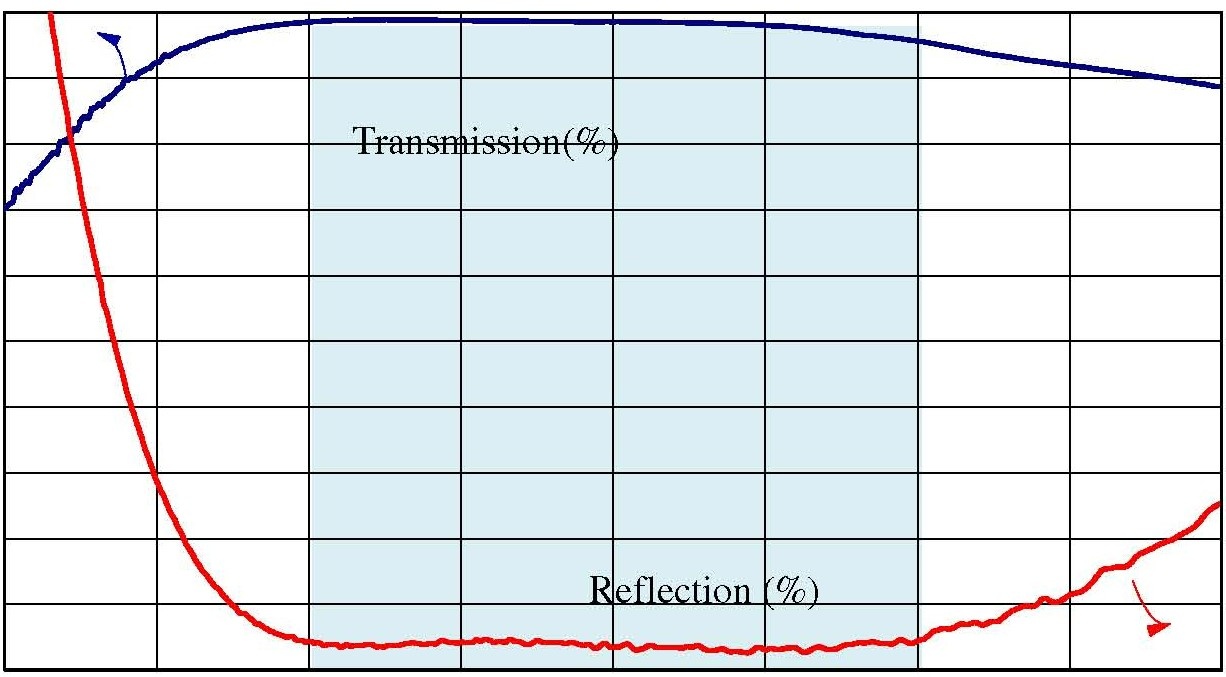

Coatings

Lightpath offers both standard, and custom optical coatings for its infrared lenses. Those include Anti Reflective (AR), High Durability AR, protective Diamond Like Carbon (DLC) coatings, as well as optional long pass, short pass and band pass filters.

All three of our global facilities are vertically integrated and include in-house coating and testing. For further information about available coatings please visit our coatings page or contact us.

Application Example

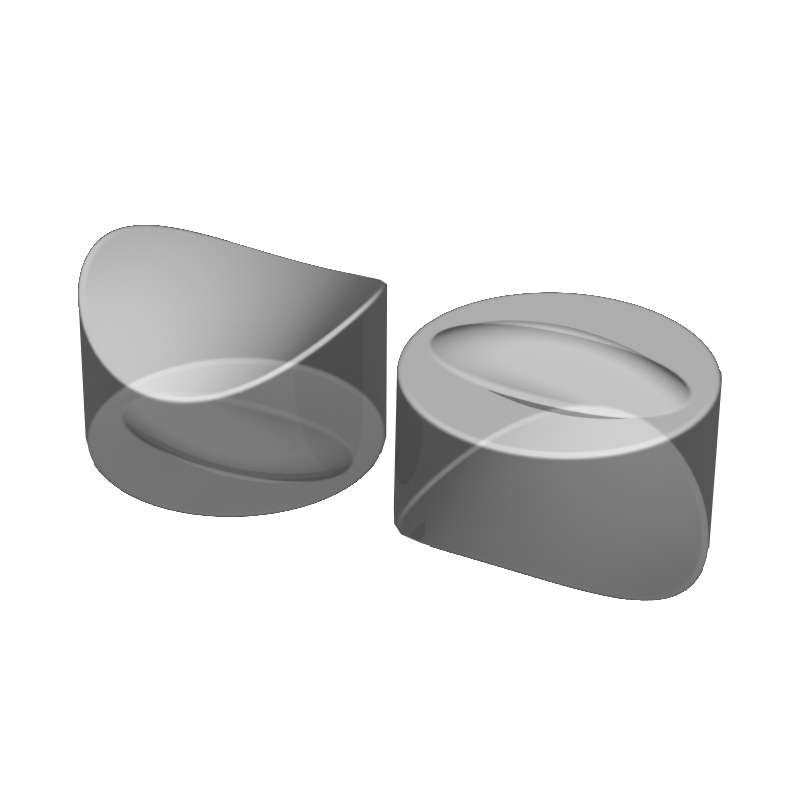

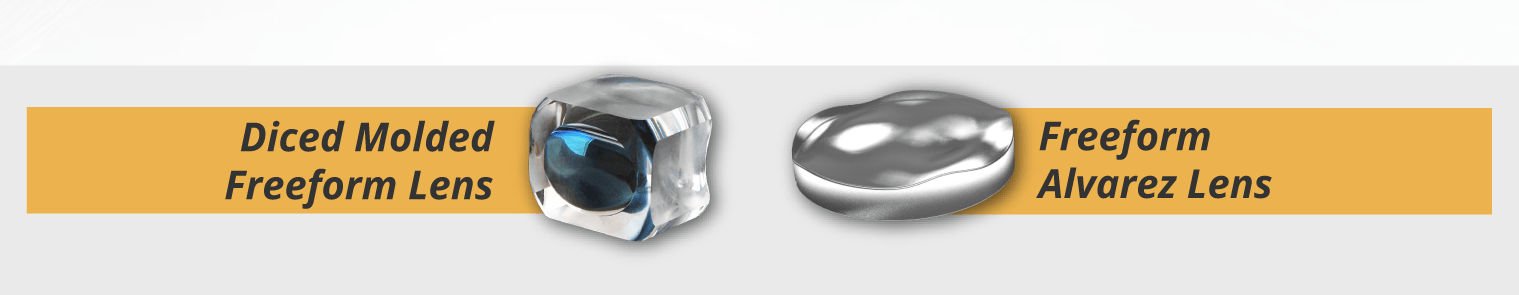

The Alvarez lens is one of the most well-known implementations of freeform optics. Each Alvarez lens is actually a pair of optical elements with matching cubic surfaces. By moving the two elements laterally relative to one another and perpendicular to the optical axis, one can adjust the optical power. The animation to the right demonstrates the use of two Alvarez lenses (total of four elements), to achieve the function of a variable zoom or a variable beam expander.

Contact