Thermal Cameras for Industrial Use: Transform Manufacturing Quality Control

Key Takeaways

Manufacturing leaders are turning to thermal cameras for industrial use technology to solve critical quality control challenges that traditional inspection methods simply cannot address.

- Real-time defect detection capabilities identify temperature variations and quality issues invisible to the naked eye

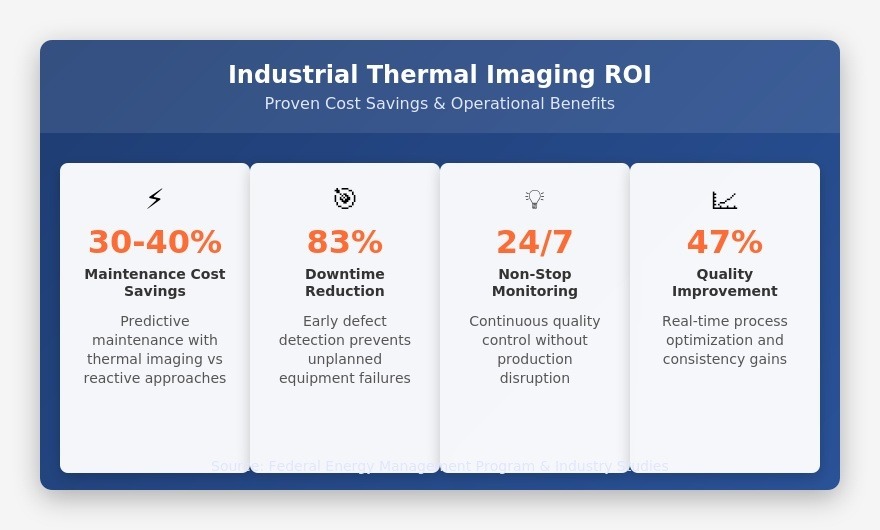

- Predictive maintenance programs using thermal imaging deliver 30-40% cost savings over reactive maintenance approaches

- Process optimization through continuous thermal monitoring improves product consistency and reduces waste

- Non-contact monitoring enables quality control without disrupting production operations

Thermal camera technology represents one of the most transformative quality control investments manufacturers can make today.

Manufacturing quality control has reached a critical inflection point. Traditional inspection methods struggle to keep pace with modern production demands, often missing defects that only become apparent after costly failures occur. The global thermal imaging market is projected to reach $7.66 billion by 2031, driven largely by industrial applications where thermal cameras for industrial use have become essential for maintaining competitive operations.

Industry leaders across manufacturing sectors are integrating thermal imaging into their quality control processes at unprecedented rates. The technology provides visibility into temperature variations, material inconsistencies, and process anomalies that directly impact product quality and operational efficiency.

Understanding Industrial Thermal Camera Capabilities

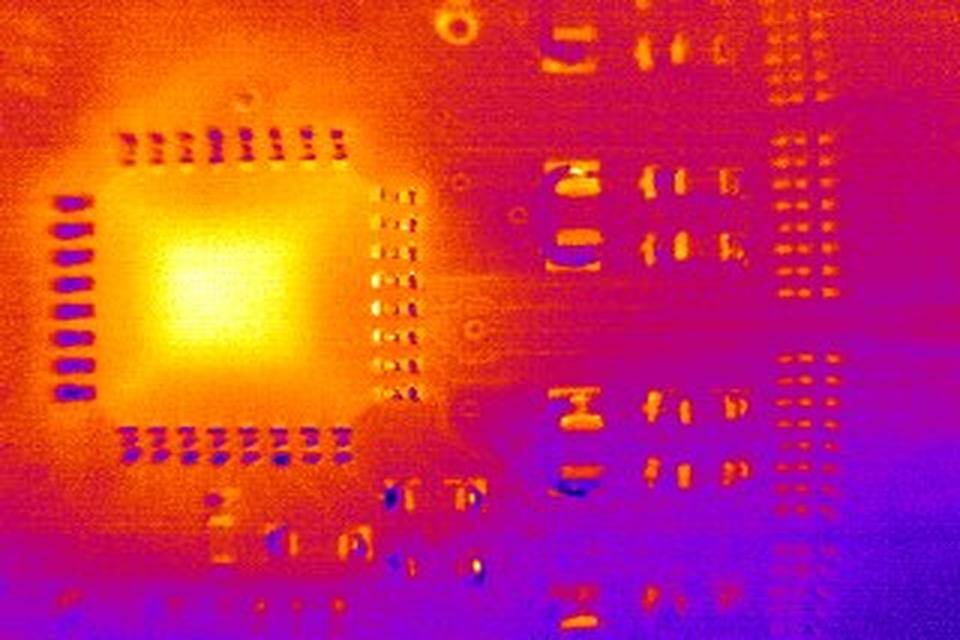

Industrial thermal cameras operate by detecting infrared radiation emitted by objects and converting this energy into visual temperature maps. Unlike traditional cameras that capture visible light, thermal cameras reveal heat signatures that indicate equipment condition, process efficiency, and potential quality issues.

The technology excels in manufacturing environments because heat often serves as an early indicator of problems. Overheating components, uneven temperature distribution, or thermal anomalies frequently signal quality defects, equipment wear, or process deviations before they become critical failures.

Modern thermal cameras for industrial use systems provide several key capabilities that make them indispensable for quality control applications. These cameras deliver real-time temperature measurement without physical contact, eliminating the need to halt production for inspections. High-resolution thermal sensors enable precise monitoring of manufacturing processes with exceptional sensitivity to temperature variations.

Advanced thermal cameras also integrate with factory automation systems, providing continuous monitoring and automatic alerts when temperature parameters exceed acceptable ranges. This integration capability allows manufacturers to build thermal monitoring directly into their production workflows, creating comprehensive thermal imaging solutions that enhance overall operational efficiency.

Seven Essential Manufacturing Applications for Thermal Cameras

#1. Process Temperature Monitoring

Thermal QC becomes critical in applications involving heating, cooling, or temperature-controlled processes. Industries such as plastics manufacturing, food processing, and chemical production rely on precise temperature control to ensure product quality and safety. Thermal cameras provide continuous monitoring of furnaces, ovens, and reaction vessels, detecting temperature variations that could compromise product specifications.

#2. Electrical System Inspection

Electrical equipment generates heat signatures that reveal connection quality, load distribution, and potential failure points. Thermal cameras identify loose connections, overloaded circuits, and component degradation before they cause equipment failures or safety hazards. Studies by the Federal Energy Management Program demonstrate that properly functioning predictive maintenance programs, including thermal imaging, provide savings of 30-40% over reactive maintenance approaches.

#3. Mechanical Component Analysis

Rotating equipment such as motors, bearings, and conveyor systems generate characteristic heat patterns during normal operation. Thermal imaging detects deviations from these baseline patterns, indicating wear, misalignment, or lubrication issues. Early detection allows maintenance teams to address problems during scheduled downtime rather than experiencing unexpected failures.

#4. Product Quality Verification

Thermal cameras excel at detecting internal defects, material inconsistencies, and structural problems that visual inspection cannot identify. In automotive manufacturing, thermal imaging verifies weld quality by detecting heat patterns that indicate proper fusion. Electronics manufacturers use thermal cameras to identify overheating components that could lead to premature failure.

#5. Seal and Insulation Testing

Manufacturing processes often require sealed containers, insulated systems, or controlled environments. Thermal cameras quickly identify seal failures, insulation gaps, or thermal bridges that compromise process integrity. This capability proves particularly valuable in pharmaceutical manufacturing, where environmental control directly impacts product quality.

#6. Material Property Assessment

Different materials exhibit distinct thermal characteristics during processing. Thermal cameras monitor these properties to ensure consistent material quality and proper processing conditions. Metal fabrication facilities use thermal imaging to verify heat treatment processes, while composite manufacturers monitor curing temperatures to ensure proper material properties.

#7. Energy Efficiency Optimization

Factory camera systems equipped with thermal imaging capabilities identify energy losses throughout manufacturing facilities. Heat mapping reveals inefficient equipment, poor insulation, and energy waste that directly impacts operational costs. Manufacturing facilities implementing thermal energy audits can achieve meaningful energy cost reductions through improved efficiency.

|

Application Area |

Primary Benefits |

Implementation Priority |

|

Process Monitoring |

Real-time quality control, reduced waste |

High - immediate impact |

|

Electrical Inspection |

Prevented failures, improved safety |

Critical - safety focused |

|

Mechanical Analysis |

Extended equipment life, planned maintenance |

Medium - long-term value |

|

Product Verification |

Reduced defects, customer satisfaction |

High - quality impact |

ROI and Cost Benefits of Industrial Thermal Imaging

The financial impact of implementing thermal cameras for industrial use technology in manufacturing quality control extends far beyond the initial equipment investment. Studies by the U.S. Department of Energy's Federal Energy Management Program demonstrate that properly functioning predictive maintenance programs, including thermal imaging, provide savings of 30-40% over reactive maintenance approaches.

Manufacturing facilities implementing comprehensive thermal imaging programs typically experience significant operational improvements. Thermal monitoring identifies potential failures before they occur, enabling proactive maintenance scheduling. Early detection and resolution of developing problems extends equipment operational life through preventive rather than reactive maintenance approaches.

The technology's non-invasive nature delivers immediate operational benefits. Unlike traditional inspection methods that require equipment shutdown, thermal cameras perform continuous monitoring without disrupting production. This capability can provide substantial value in high-volume manufacturing environments where unexpected downtime creates significant operational and financial impact.

Energy cost reductions represent another significant benefit category. Thermal imaging identifies inefficient equipment, improper insulation, and energy waste throughout manufacturing facilities. Companies implementing thermal energy audits can achieve meaningful reductions in energy costs through improved operational efficiency.

Quality improvement metrics also demonstrate substantial value. Thermal QC systems reduce defect rates through early detection of process deviations and material inconsistencies. This improvement translates directly to reduced warranty costs, improved customer satisfaction, and enhanced brand reputation.

Implementation Best Practices for Manufacturing Environments

Successful thermal imaging implementation requires strategic planning and systematic deployment. Manufacturing facilities should begin by identifying critical processes, equipment, and quality control points where thermal monitoring provides the greatest value. This assessment helps prioritize initial deployments and maximize early returns on investment.

Establishing baseline thermal signatures for normal operations becomes essential for effective monitoring. Factory camera systems must capture thermal images of equipment and processes under various operating conditions to create reference patterns. These baselines enable automated detection of anomalies and reduce false alarms that can undermine confidence in the system.

Training personnel represents a critical success factor often overlooked during implementation. Maintenance technicians, quality control staff, and production operators need to understand thermal imaging principles and interpretation techniques. Proper training ensures that thermal data translates into actionable insights rather than overwhelming information.

Integration with existing manufacturing systems amplifies thermal imaging benefits. Modern thermal cameras can connect to plant automation systems, quality management software, and maintenance management platforms. This integration enables automated data collection, trend analysis, and predictive alerts that support decision-making across comprehensive optical solutions portfolios.

Regular calibration and maintenance of thermal imaging equipment ensures accurate and reliable measurements. Manufacturing environments can be challenging for sensitive equipment, making proper care essential for long-term success. Establishing calibration schedules and maintenance procedures protects the investment and maintains measurement accuracy.

|

Implementation Phase |

Key Activities |

Success Metrics |

|

Assessment |

Identify critical applications, baseline establishment |

Clear ROI projections |

|

Deployment |

Equipment installation, initial training |

System operational |

|

Optimization |

Process integration, advanced training |

Measurable improvements |

|

Expansion |

Additional applications, system scaling |

Sustained benefits |

Technology Integration and Advanced Capabilities

Modern thermal cameras for industrial use systems integrate seamlessly with other manufacturing technologies to create comprehensive monitoring solutions. Combining thermal imaging with vibration analysis, for example, provides complete condition monitoring for rotating equipment. This multi-technology approach improves diagnostic accuracy and reduces false positives.

Artificial intelligence and machine learning enhance thermal imaging capabilities by automating pattern recognition and anomaly detection. AI-powered thermal analysis systems learn normal operating patterns and automatically identify deviations that require attention. This automation reduces the burden on personnel while improving response times to developing problems.

Cloud connectivity enables remote monitoring and centralized management of multiple manufacturing facilities. Thermal data can be aggregated across locations, enabling comparative analysis and best practice sharing. Remote monitoring capabilities also support expert consultation and troubleshooting without requiring on-site visits.

Data analytics platforms transform thermal measurements into actionable business intelligence. Trend analysis identifies gradual changes that might otherwise go unnoticed, while predictive algorithms forecast potential issues based on historical patterns. These analytical capabilities support strategic decision-making about equipment replacement, process optimization, and maintenance scheduling.

Integration with Internet of Things (IoT) platforms creates opportunities for comprehensive smart manufacturing implementations. Thermal cameras become sensors in larger connected systems that optimize entire production processes based on real-time conditions. This level of integration represents the future of manufacturing quality control, especially when combined with advanced thermal imaging lens assemblies designed for industrial applications.

Advanced thermal cameras now incorporate multiple spectral bands to provide enhanced material characterization. These multi-spectral capabilities enable detection of specific materials, chemical compositions, and process conditions that single-band thermal imaging cannot identify. Such advanced capabilities expand the range of quality control applications significantly.

Choosing the Right Thermal Imaging Solution

Selecting appropriate thermal cameras for industrial use technology requires careful consideration of specific manufacturing requirements and operational constraints. Camera resolution, temperature range, and measurement accuracy must align with intended applications. Higher resolution cameras provide more detailed thermal images but typically require larger investments.

Environmental conditions in manufacturing facilities influence camera selection significantly. Dusty environments, high ambient temperatures, and vibration levels all affect camera performance and longevity. Industrial-grade thermal cameras designed for harsh environments ensure reliable operation in challenging manufacturing conditions.

Connectivity requirements vary depending on integration needs and facility infrastructure. Ethernet connectivity enables integration with plant networks, while wireless capabilities provide flexibility in camera placement. Some applications require real-time data streaming, while others can operate with periodic data collection.

Software capabilities often determine the long-term value of thermal imaging systems. Basic temperature measurement suffices for simple applications, while advanced analytics, automated reporting, and predictive algorithms provide greater value for complex manufacturing environments. Scalable software platforms accommodate growing requirements over time.

Support and service capabilities become critical for maintaining thermal imaging systems in manufacturing environments. Local technical support, calibration services, and replacement part availability ensure minimal downtime when issues occur. Comprehensive service agreements protect the investment and maintain system performance.

Future Developments in Manufacturing Thermal Imaging

The evolution of thermal cameras for industrial use technology continues to expand capabilities while reducing costs, making thermal imaging accessible to smaller manufacturers. Higher resolution sensors, improved sensitivity, and enhanced software capabilities deliver better performance at lower price points than previous generations.

Miniaturization trends enable integration of thermal imaging into manufacturing equipment and production lines. Embedded thermal sensors can monitor specific process points without requiring separate camera installations. This integration approach reduces implementation complexity while providing targeted monitoring capabilities.

Artificial intelligence development promises to revolutionize thermal image analysis and interpretation. Machine learning algorithms will automatically identify optimal thermal signatures for specific applications and continuously improve detection accuracy based on operational data. These advances will make thermal imaging more effective and easier to implement.

Edge computing capabilities enable real-time processing of thermal data without requiring network connectivity. Local processing reduces latency and enables immediate responses to thermal anomalies. Edge computing also addresses data security concerns by keeping sensitive thermal information within manufacturing facilities.

Frequently Asked Questions

What temperature accuracy can industrial thermal cameras achieve? Modern industrial thermal cameras provide high temperature accuracy suitable for precise manufacturing applications. Calibration and environmental conditions significantly impact measurement accuracy, making proper setup and maintenance essential for reliable results.

How do thermal cameras integrate with existing quality management systems? Most industrial thermal cameras offer multiple connectivity options including Ethernet, USB, and wireless protocols. Standard communication interfaces enable integration with SCADA systems, manufacturing execution systems, and quality management platforms.

What training is required for personnel to effectively use thermal imaging? Basic thermal imaging operation requires brief introductory training, while advanced thermography certification programs require more extensive instruction. Ongoing training ensures personnel stay current with evolving best practices and technology capabilities.

Can thermal cameras operate reliably in harsh manufacturing environments? Industrial-grade thermal cameras are designed for harsh environments with protection ratings up to IP67. These cameras withstand temperature extremes, dust, moisture, and vibration commonly found in manufacturing facilities.

Transform Your Manufacturing Quality Control Today

Thermal cameras for industrial use technology have evolved from specialized diagnostic tools to essential manufacturing infrastructure. The compelling ROI, proven cost savings, and operational improvements make thermal imaging a strategic investment for manufacturers committed to quality excellence and operational efficiency.

The key to successful implementation lies in partnering with experienced thermal imaging specialists who understand manufacturing requirements and can provide comprehensive solutions tailored to specific applications. From initial assessment through ongoing support, the right partner ensures maximum value from thermal imaging investments.

LightPath Technologies brings four decades of optical and thermal imaging expertise to manufacturing quality control challenges. Our industrial-grade thermal imaging solutions deliver the precision, reliability, and integration capabilities that modern manufacturers demand. Contact our experts to discover how thermal camera technology can transform your manufacturing quality control processes.