Are Infrared Security Cameras Enough for Defense Applications?

Key Takeaways

For aerospace, defense, and critical infrastructure applications, IR-illuminated infrared security cameras cannot deliver the detection range, reliability, or performance required for mission-critical perimeter security.

- IR-illuminated systems rely on active near-infrared lighting with inherent range limitations under 100 meters

- Thermal infrared security cameras provide passive detection at ranges exceeding 1000 meters for personnel

- Optical quality and lens materials determine real-world performance more than sensor specifications alone

- Supply chain considerations for traditional germanium optics have driven innovation in alternative materials

Engineering teams should evaluate thermal infrared security camera systems based on detection requirements, environmental operating conditions, and optical subsystem quality for OEM integration.

The perimeter security market continues fragmenting as marketing materials blur distinctions between fundamentally different imaging technologies. For OEMs developing defense systems, critical infrastructure protection platforms, or industrial monitoring solutions, understanding the technical limitations of IR-illuminated cameras versus true thermal imaging capabilities is essential for meeting performance requirements.

IR-illuminated infrared security cameras dominate commercial security markets through aggressive pricing and "night vision" marketing claims. However, these systems operate on visible-light imaging principles with near-infrared LED supplementation. For applications demanding reliable long-range detection, all-weather operation, and mission-critical performance, thermal infrared security cameras provide capabilities that IR-illuminated systems cannot match.

This technical overview addresses the engineering considerations, optical requirements, and performance limitations relevant to OEM integration of perimeter detection systems for demanding applications.

Why Do IR-Illuminated Cameras Fall Short for Defense Applications?

IR-illuminated infrared security cameras represent visible-light imaging technology with near-infrared LED arrays providing invisible illumination. These systems operate in the near-infrared spectrum (typically 850-940nm), just beyond visible light wavelengths. The camera sensor captures reflected near-IR radiation from objects illuminated by the LED array, producing grayscale images in darkness.

This approach introduces several fundamental limitations for perimeter security applications. Detection range is constrained by LED illuminator power and efficiency. While manufacturers claim detection ranges of 100-300 feet, effective identification ranges are significantly shorter. The inverse square law governs illumination intensity, meaning doubling the distance requires four times the LED power for equivalent illumination levels.

IR-illuminated systems remain dependent on reflected light energy, inheriting the same contrast limitations as visible-light cameras. Dark objects against dark backgrounds provide poor contrast even with IR illumination. This limits effectiveness for detecting camouflaged or low-contrast targets that defense and security applications must reliably identify.

Active illumination creates detectability concerns. Near-IR LEDs are invisible to human eyes but readily visible to night vision devices and other IR-sensitive equipment. For covert surveillance or applications where adversaries may employ counter-surveillance technology, active IR illumination compromises system effectiveness. According to research on advancing military camouflage, traditional camouflage methods that work against visible and near-IR imaging are increasingly ineffective, highlighting the arms race in detection technologies.

Environmental factors further constrain performance. Smoke, fog, and precipitation scatter near-IR wavelengths, dramatically reducing effective range. The same conditions that limit visible-light camera performance similarly degrade IR-illuminated infrared security camera capability.

Thermal Imaging: Passive Detection Architecture

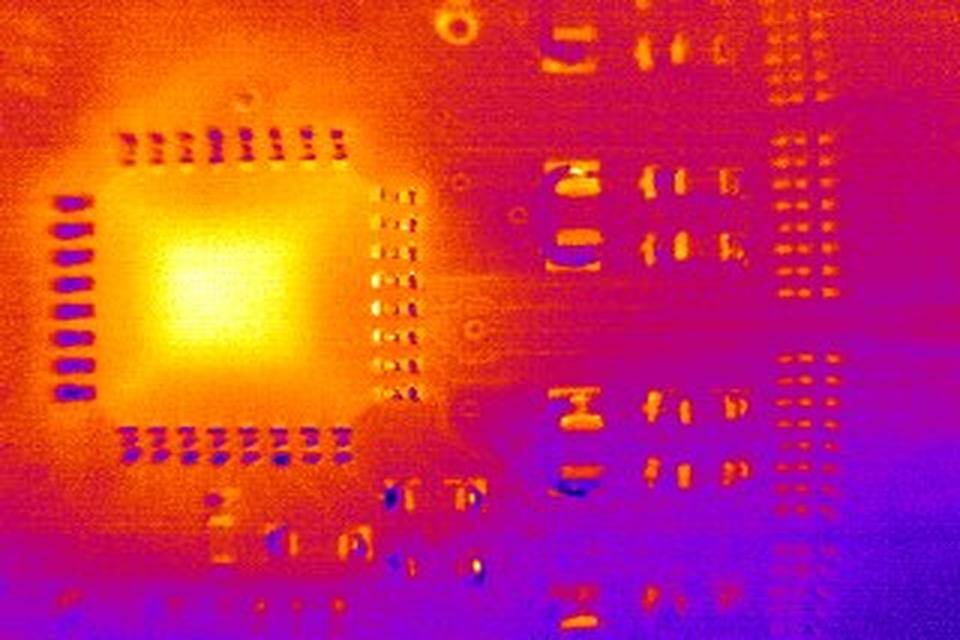

Thermal infrared security cameras operate on fundamentally different principles, detecting mid-wave infrared (MWIR, 3-5µm) or long-wave infrared (LWIR, 8-14µm) radiation emitted by objects based on their temperature. This passive detection approach eliminates dependence on external illumination while providing detection capabilities that IR-illuminated systems cannot achieve.

All objects above absolute zero emit thermal radiation according to blackbody radiation principles. Warmer objects emit more thermal energy than cooler ones, creating temperature contrast that thermal sensors detect. Humans, vehicles, and operating equipment generate heat signatures distinct from ambient backgrounds, enabling reliable detection regardless of visible contrast or lighting conditions.

Thermal sensors, typically utilizing microbolometer technology for LWIR applications or photon detectors for MWIR systems, measure incident thermal radiation and convert it to electrical signals. Processing electronics generate thermal images where brightness correlates to temperature, making warmer targets immediately apparent against cooler backgrounds.

This passive architecture provides several operational advantages for perimeter security. Research on long-range thermal target detection demonstrates that thermal cameras with appropriate sensors can detect targets from distances of 5 kilometers or more. Long-range thermal systems routinely detect human targets beyond 1000 meters and vehicles at 2000+ meters, far exceeding IR-illuminated camera capabilities.

Environmental performance represents another critical distinction. While both visible-light and near-IR wavelengths scatter significantly in fog, smoke, and precipitation, LWIR and MWIR wavelengths penetrate these conditions more effectively. Thermal infrared security cameras maintain operational capability in environmental conditions that render IR-illuminated systems nearly useless for perimeter detection.

How Do IR-Illuminated and Thermal Cameras Compare in Real-World Performance?

Understanding real-world performance differences between IR-illuminated and thermal infrared security cameras requires examining how each technology responds to operational scenarios.

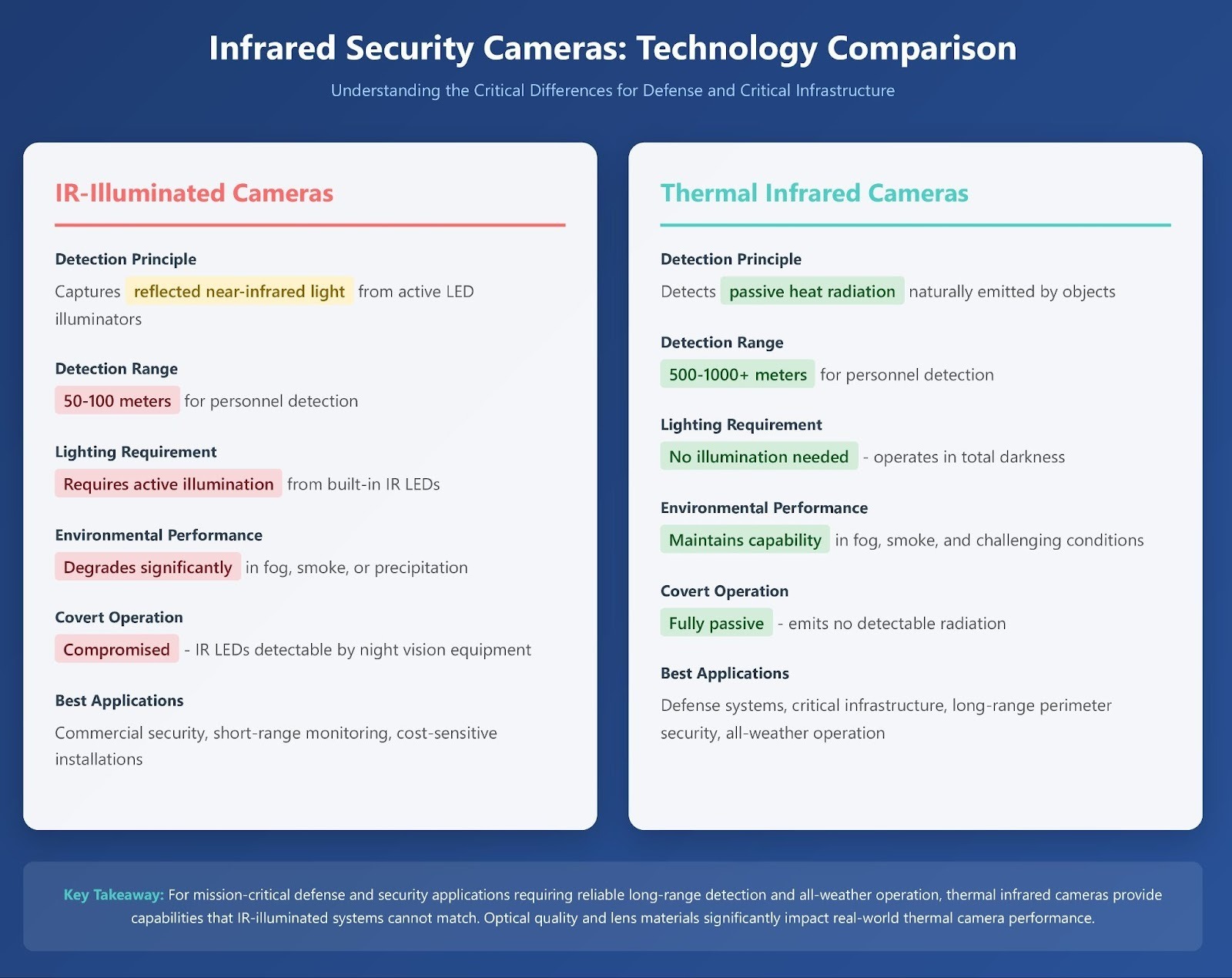

Range Limitations fundamentally distinguish these technologies. IR-illuminated systems typically provide person detection at 50-100 meters under optimal conditions, with identification ranges substantially shorter. Thermal systems routinely detect personnel at 500+ meters and vehicles beyond 1000 meters. For perimeter applications requiring extended detection ranges to provide adequate response time, IR-illuminated technology cannot meet requirements.

Contrast and Target Detection capabilities differ significantly. IR-illuminated cameras detect reflected near-IR radiation, requiring contrast between target and background similar to visible-light imaging. Camouflaged targets, low-contrast scenarios, and targets matching background appearance challenge these systems. Thermal infrared security cameras detect temperature differences, making warm targets like humans and vehicles immediately apparent against cooler backgrounds regardless of visual camouflage.

Environmental Resilience varies dramatically between technologies. IR-illuminated systems perform adequately in clear conditions with good LED illumination but degrade rapidly in fog, smoke, or precipitation. Thermal imaging maintains substantially better performance in these conditions because longer infrared wavelengths penetrate atmospheric interference more effectively. For defense and aerospace applications requiring all-weather operation, this performance difference is critical.

Covert Operation requirements may determine technology selection for certain applications. IR-illuminated systems emit near-infrared radiation detectable by night vision devices and IR sensors. Thermal infrared security cameras operate passively, emitting no illumination that could reveal camera positions or alert adversaries to surveillance.

|

Performance Factor |

IR-Illuminated Systems |

Thermal Infrared Cameras |

|

Detection Range (Person) |

50-100m |

500-1000m+ |

|

Contrast Dependency |

High (requires visual contrast) |

Low (detects temperature) |

|

Environmental Performance |

Degrades significantly |

Maintains capability |

|

Covert Operation |

Compromised (active emission) |

Fully passive |

|

Day/Night Operation |

Requires mode switching |

Continuous operation |

Why Optical Quality Determines System Performance

While sensor technology receives primary attention in infrared security camera specifications, optical subsystem quality fundamentally determines whether systems achieve theoretical performance in operational deployments. For OEM integration, understanding optical considerations is essential for delivering reliable products.

Lens Material Selection significantly impacts thermal infrared security camera performance. Traditional thermal optics rely on germanium, which offers excellent transmission in LWIR wavelengths but faces supply chain constraints and cost challenges. Germanium availability fluctuations create procurement uncertainty for OEMs developing production systems.

Alternative lens materials including chalcogenide glasses and specialized optical designs maintain thermal transmission characteristics while providing more stable supply chains. These materials require sophisticated optical engineering to achieve performance comparable to germanium optics, but offer significant advantages for production programs requiring predictable component availability.

Optical Design Optimization affects system performance through multiple parameters. Cold shield efficiency in cooled MWIR systems determines image uniformity and eliminates corner shading artifacts. Lens f-number and focal length directly impact both detection range and field of view. Athermalization ensures consistent focus across operating temperature ranges without requiring active focus mechanisms.

For OEMs integrating infrared security cameras into larger systems, optical subsystem specification and supplier selection significantly impact final product performance. Procuring thermal cameras as black boxes without understanding optical quality often results in systems that meet datasheet specifications but underperform in operational conditions.

Coating Technology optimizes transmission efficiency and protects optical surfaces. Specialized anti-reflection coatings for LWIR and MWIR wavelengths minimize reflection losses at air-glass interfaces. Environmental protection coatings resist degradation from moisture, salt spray, and chemical exposure in harsh deployment environments.

What Integration Factors Should OEMs Consider for Infrared Security Cameras?

Engineers integrating infrared security cameras into defense systems, surveillance platforms, or industrial monitoring applications face technical considerations beyond camera specifications.

Interface Requirements must accommodate both video data and control signals. Thermal infrared security cameras typically provide digital video outputs via Ethernet, SDI, or specialized interfaces. Integration requires verifying interface compatibility with existing video processing infrastructure and ensuring adequate bandwidth for thermal imagery.

Power Specifications vary significantly between camera types. Uncooled LWIR thermal cameras typically require 5-15W, suitable for PoE or battery-powered applications. Cooled MWIR systems may require 20-50W or more, particularly during cooldown cycles. IR-illuminated cameras require additional power for LED arrays, often exceeding thermal camera requirements despite lower sensor complexity.

Mechanical Integration considerations include mounting interfaces, cable management, and environmental protection. Military and defense applications often require MIL-STD qualification including vibration, shock, and temperature cycling. Critical infrastructure applications may require NEMA or IP ratings for weather resistance along with compliance to specific regulatory standards.

Supply Chain and Material Considerations

For OEMs planning production programs, supply chain stability and material availability significantly impact program risk and cost management.

Germanium Availability presents ongoing challenges for traditional thermal optics. Global germanium supply concentrates in limited sources, creating vulnerability to supply disruptions and price volatility. Programs requiring large camera quantities or multi-year production runs face significant procurement risk with germanium-based optics.

Alternative Optical Materials including proprietary chalcogenide glasses provide equivalent performance with improved supply chain stability. These materials enable thermal infrared security camera production without dependence on constrained material sources. For OEMs, alternative optics provide program security and cost predictability throughout production lifecycles.

Export Considerations affect international programs. Thermal imaging technology faces export restrictions under ITAR and Wassenaar Arrangement provisions. Some components and assemblies require export licenses for international customers. OEMs developing products for global markets must ensure compliance and consider how export restrictions affect market access.

When Should You Choose Thermal Over IR-Illuminated Cameras?

For OEMs and system integrators, technology selection should be driven by application requirements, not just procurement cost.

When IR-Illuminated May Be Adequate includes close-range applications with short detection requirements under 100 meters, controlled environments with predictable lighting, and commercial applications where cost constraints override performance requirements. These systems serve retail security, parking surveillance, and similar applications where limited detection ranges suffice.

When Thermal Is Essential encompasses defense applications, critical infrastructure protection, long-range perimeter security, covert surveillance requirements, and any application demanding all-weather operation. For systems where detection failure creates security vulnerabilities or threatens mission success, thermal infrared security cameras provide the only viable solution. According to data breach research, security failures continue imposing severe financial consequences, reinforcing the importance of choosing technologies adequate for protection requirements.

Cost Considerations must account for total system cost, not just camera procurement. IR-illuminated systems require more cameras for equivalent coverage due to shorter ranges, increasing installation costs and infrastructure requirements. Thermal systems with longer ranges may reduce total system costs despite higher per-camera prices.

6 Critical Factors When Selecting Thermal Infrared Security Cameras for Defense

When evaluating thermal infrared security cameras for mission-critical applications, these six factors separate adequate systems from optimal solutions:

- Detection Range Requirements Match camera specifications to operational needs. Defense perimeter applications typically require detection ranges of 500+ meters for personnel and 1000+ meters for vehicles. Verify that quoted ranges account for realistic target sizes and environmental conditions rather than idealized laboratory performance.

- Optical Subsystem Quality Lens material, coating technology, and optical design impact performance more than sensor specifications alone. Cold shield efficiency in cooled systems and athermalization across temperature ranges directly affect image quality. Request detailed optical specifications beyond basic sensor parameters.

- Environmental Operating Conditions Consider deployment environment extremes. While thermal cameras outperform IR-illuminated systems in challenging conditions, heavy precipitation and extreme temperatures still affect performance. Ensure specifications include operational temperature ranges, weather resistance ratings, and validated environmental testing results.

- Supply Chain Stability Traditional germanium optics face availability constraints and price volatility. Alternative optical materials including proprietary chalcogenide glasses provide equivalent performance with improved supply chain predictability. For multi-year production programs, material availability matters as much as performance specifications.

- Integration Compatibility Verify interface compatibility with existing infrastructure. Modern thermal cameras support various digital outputs, but confirming VMS integration, bandwidth requirements, and power specifications before procurement avoids costly integration challenges. Edge analytics capabilities should align with system architecture decisions.

- Export Compliance and Regulatory Requirements Thermal imaging technology faces ITAR and Wassenaar Arrangement restrictions. For international programs or defense applications, ensure supplier experience with export licensing and compliance documentation. Regulatory requirements may limit technology options or affect delivery schedules.

Frequently Asked Questions

What's the actual difference between IR-illuminated and thermal infrared security cameras?

IR-illuminated cameras use visible-light sensors with near-infrared LED illuminators, essentially night-vision-enabled CCTV cameras. Thermal infrared security cameras detect heat radiation in MWIR or LWIR wavelengths, operating on completely different principles. Thermal provides vastly superior range and environmental performance for demanding applications.

Why are thermal infrared security cameras more expensive?

Thermal sensors require specialized detector materials and complex fabrication processes. Optical components use materials like germanium or specialized chalcogenides rather than conventional glass. However, for applications requiring long-range detection, fewer thermal cameras may be needed compared to multiple IR-illuminated cameras, potentially reducing total system costs.

Can thermal cameras identify individuals for security purposes?

Thermal imaging detects heat signatures, not facial features or identifying details. For security applications, thermal provides detection and tracking while separate visible-light cameras handle identification. Many systems combine thermal detection with visible verification, using each technology for its optimal purpose.

What optical considerations matter most for thermal camera selection?

Lens quality, material selection, and optical design significantly impact real-world performance. Cold shield efficiency in cooled systems, athermalization for temperature stability, and coating quality all affect whether cameras achieve specified performance in operational deployments. Optical subsystem quality often distinguishes professional systems from budget alternatives.

How do export restrictions affect thermal infrared security cameras?

Thermal imaging technology faces export controls under ITAR and Wassenaar Arrangement. Higher-performance systems may require export licenses for international customers. OEMs developing products for global markets should work with suppliers experienced in export compliance to ensure market access.

Selecting the Right Technology for Mission-Critical Applications

For aerospace, defense, and critical infrastructure applications, infrared security camera technology selection directly impacts system effectiveness and mission success. IR-illuminated cameras serve commercial security markets adequately but cannot deliver the detection range, environmental performance, and reliability that demanding applications require.

Thermal infrared security cameras provide proven capability for long-range detection, all-weather operation, and covert surveillance. Success requires attention to optical quality, integration requirements, and supply chain considerations beyond basic camera specifications. Engineering teams should evaluate complete solutions including optics, sensors, and integration support rather than procuring cameras as commodity products.

For over four decades, LightPath Technologies has engineered precision optical solutions and thermal imaging systems for aerospace, defense, and industrial OEM partners. Our comprehensive capabilities span proprietary optical materials, lens assemblies, and complete camera systems designed for integration into mission-critical platforms.

From alternative optical materials that reduce supply chain risk to complete thermal imaging assemblies, we deliver solutions engineered specifically for OEM production programs. Contact our engineering team to discuss your thermal imaging requirements and discover how our optical expertise can enhance your system performance.