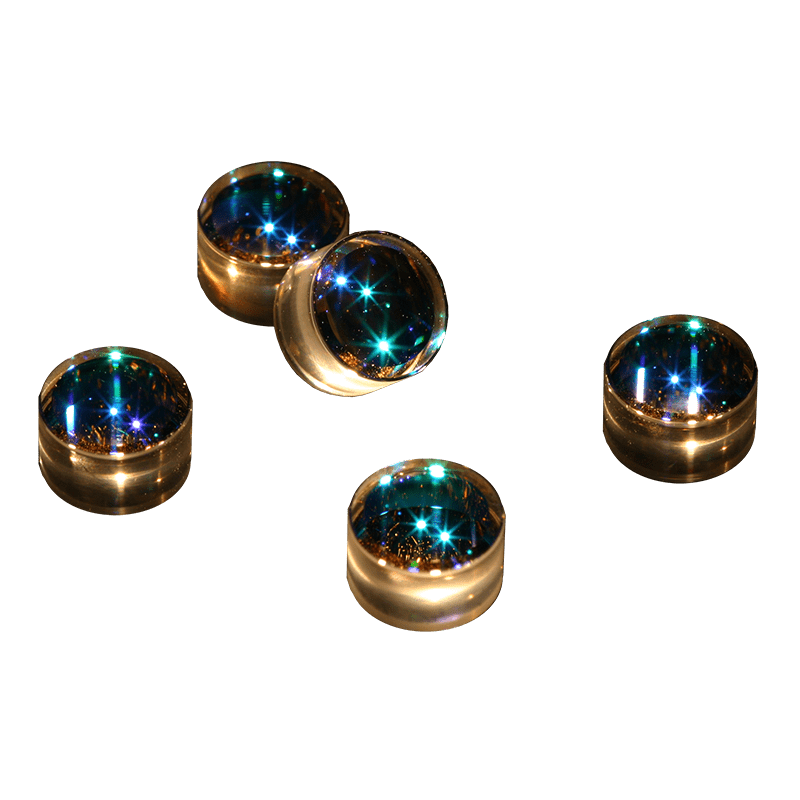

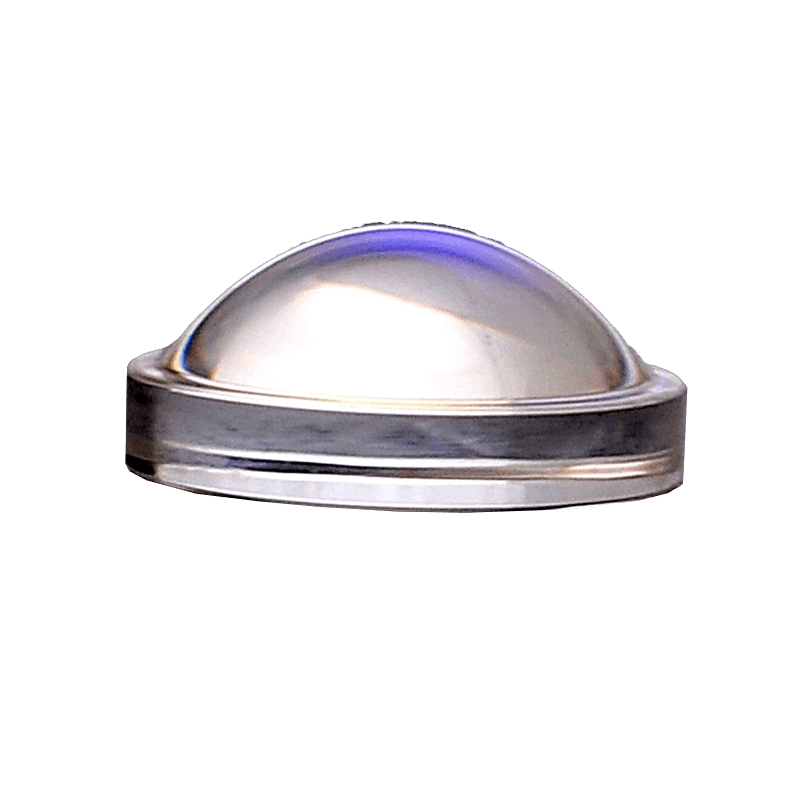

Molded Glass Aspheres

Molded Glass Aspheres

4 Million Lenses Produced Annually

Standard and Custom Designs Available

Diameters from Sub millimeter to over 50mm

Overview

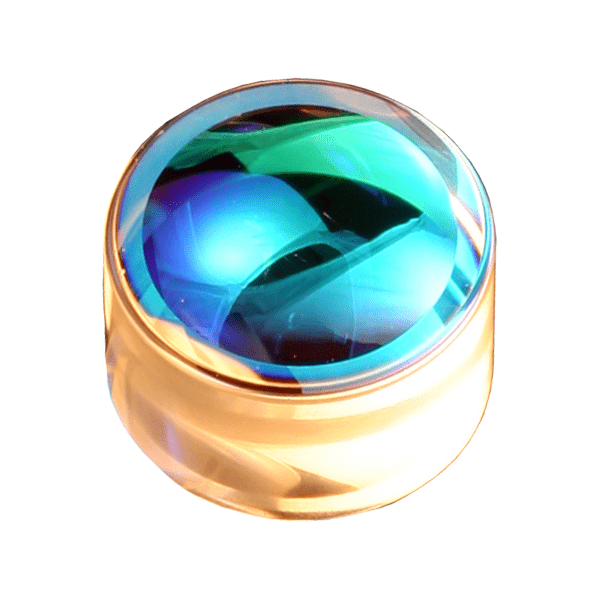

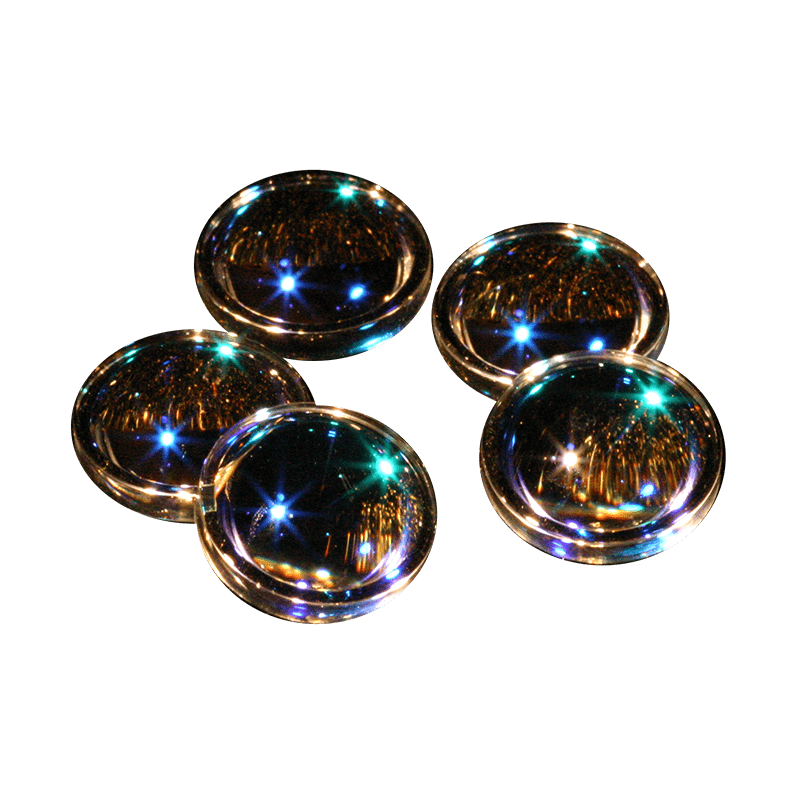

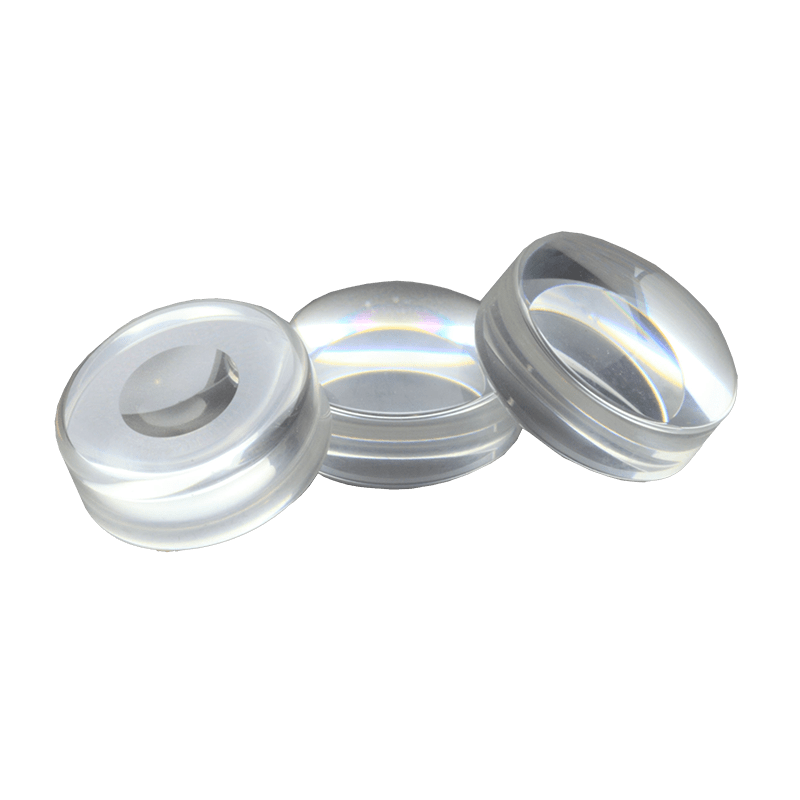

LightPath’s glass molding technology has enabled high volume production of aspheric optics while maintaining the highest quality at an affordable price. Because molding is the most consistent and economical way to produce aspheres in large volumes, LightPath has perfected this method to offer the most precise aspheric lens available. LightPath offers standard and custom-made lenses, all designed by our expert optical design engineers.

- Benefit from the quality and performance of all-glass aspheres

- Easily transition from prototype phase to high-volume production

- Customize to fit your application or choose from over 100 standard aspheric designs

- RoHS-compliant, ultra-high quality glass

Typical Tolerances

| Parameter | Specification |

|---|---|

| Focal Length |

± 1% |

| Center Thickness (CT) |

± 0.025 mm |

| Outer Diameter (OD) |

± 0.015 mm |

| Wedge |

4 arcmin |

| Power/Irregularity |

3/1 fringes |

| Surface Roughness |

15nm |

| Surface Quality (scratch/dig) |

40/20 |

| Wave Front Error (RMS) |

Diffraction Limited |

Materials

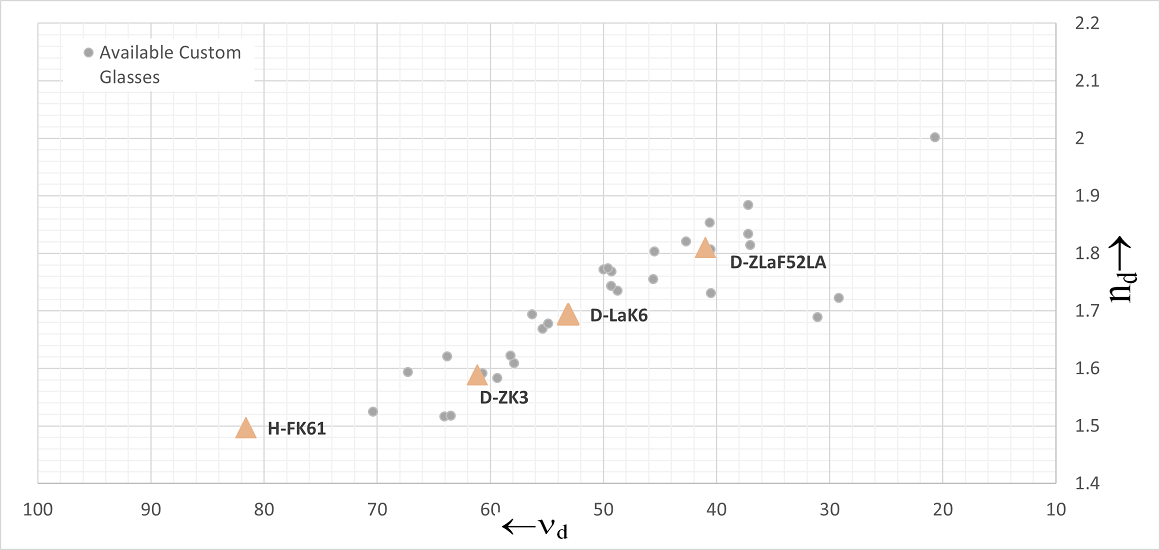

Lightpath produces molded aspherical lenses and molded freeform lenses out of a variety of materials. The Abbe chart below depicts materials that LightPath most recommends using, as well as additional materials that could be used for molded optics.

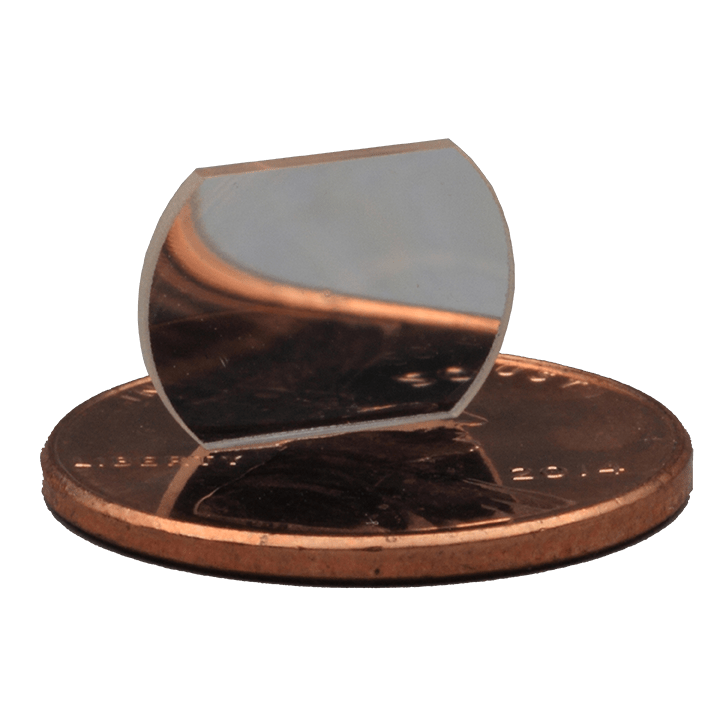

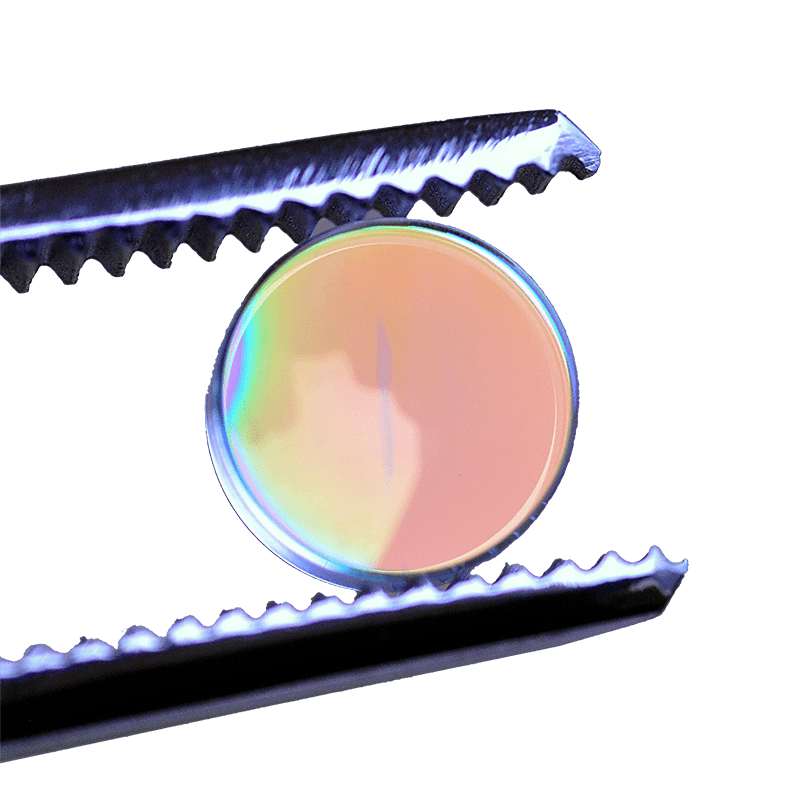

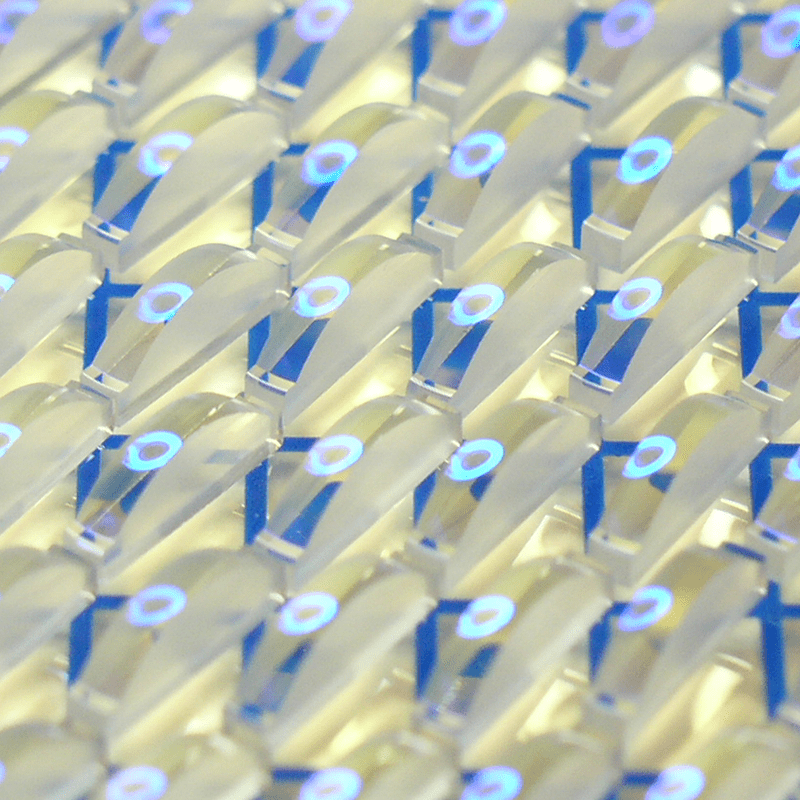

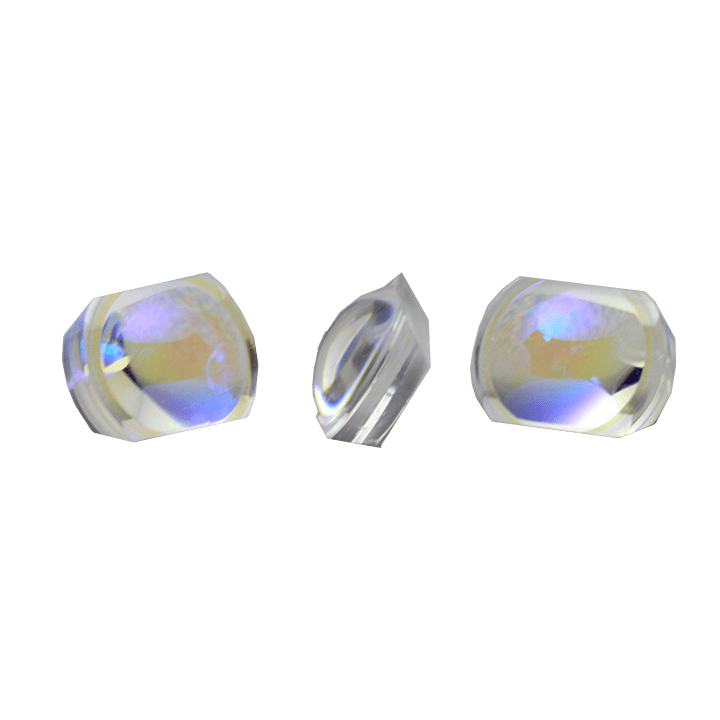

Precision Optical Molding

Precision glass molding (PGM) is a high-temperature, isothermal, compression process conducted within a very controlled environment. LightPath has an extensive innovative history with glass molding and a uses a unique volumetric approach which eliminates the need for any post processing or edging since the exact volume of the glass (preform) is specifically matched to the final lens. We custom design and manufacture in our Orlando headquarters the lens specific molds and tooling from a variety of materials using a variety of in-house developed techniques. Our molding stations are also designed and customed in house which allows system reproducibility and process control with our single cavity press stations across our global manufacturing locations.

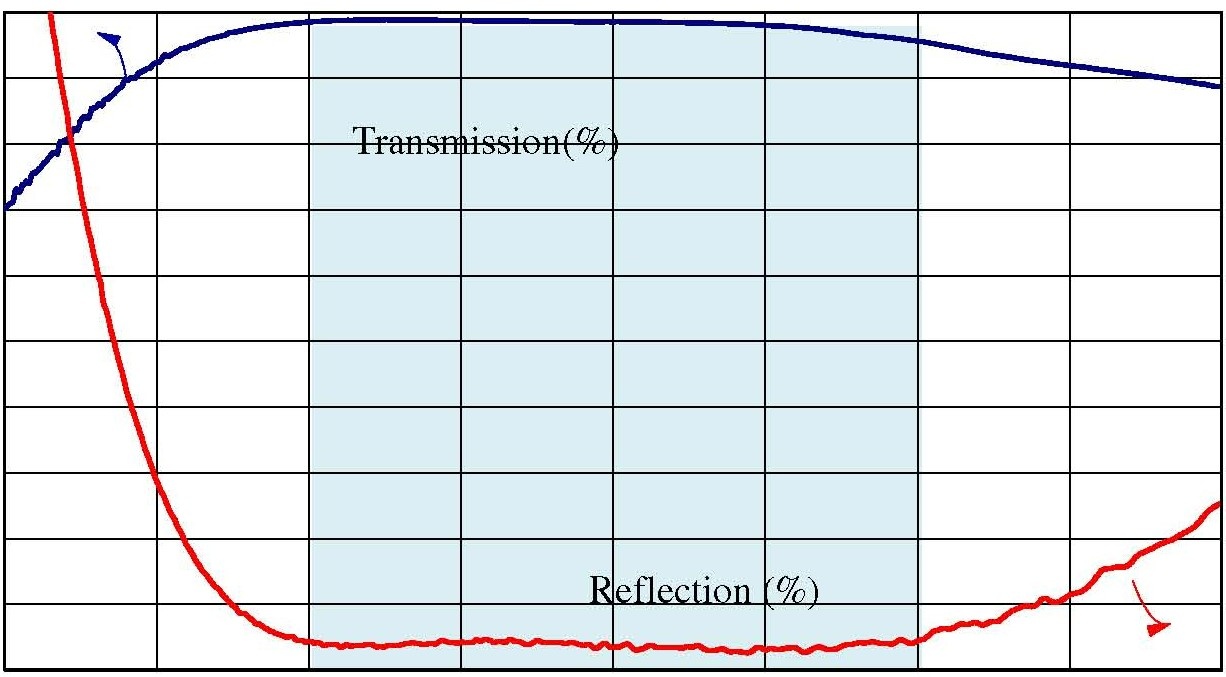

Coatings

Lightpath offers both standard, and custom optical coatings for its infrared prisms. Those include Anti Reflective (AR), High Durability AR, Spectral Filters, and protective Diamond Like Carbon (DLC) coatings.

All three of our global facilities are vertically integrated and include in-house coating and testing. For further information about available coatings please visit our coatings page or contact us.

Downloads

Contact