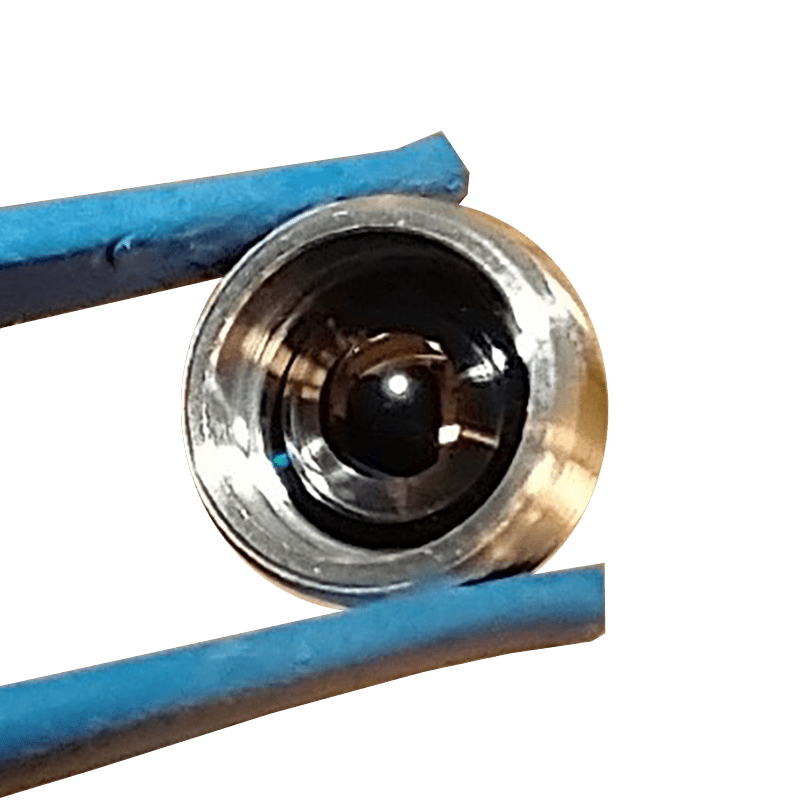

Demonstration of welding of a Black Diamond lens into place using an IPG YLR-300/3000-QCW Laser, D30 Welding head and IPG’S Compact Multi-Axis system.

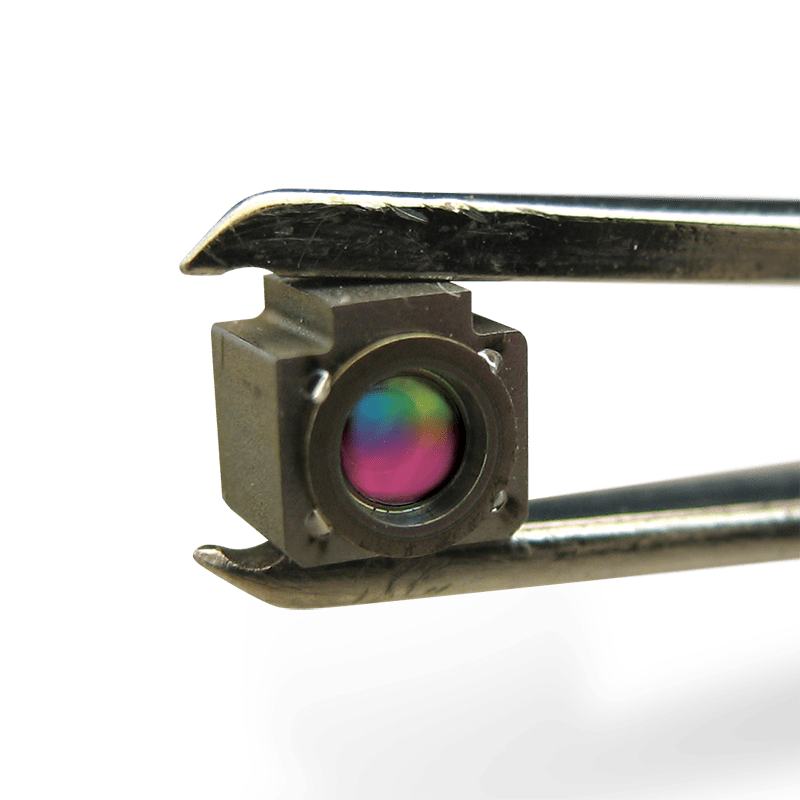

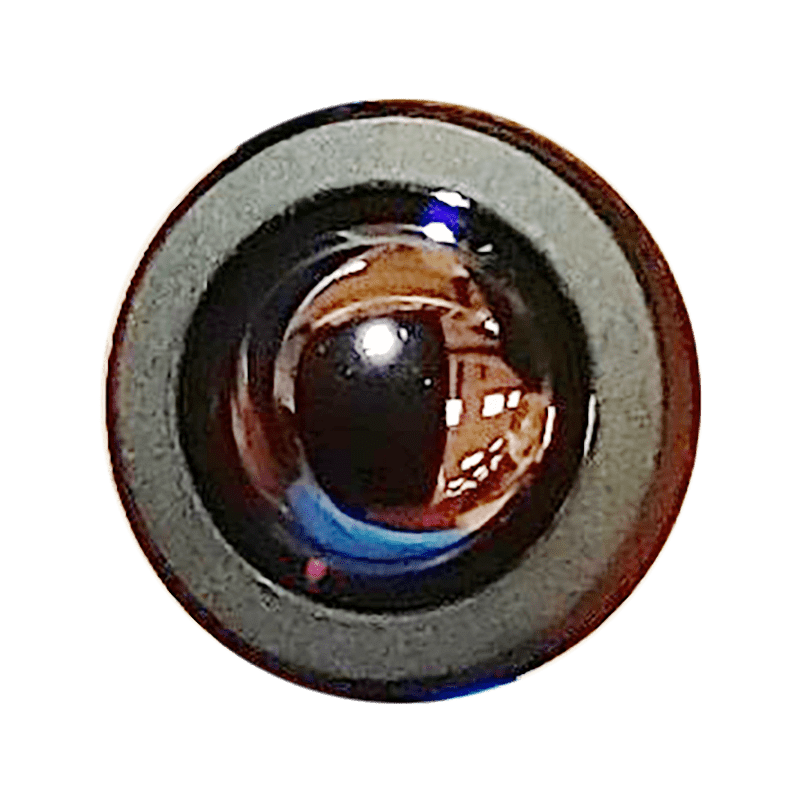

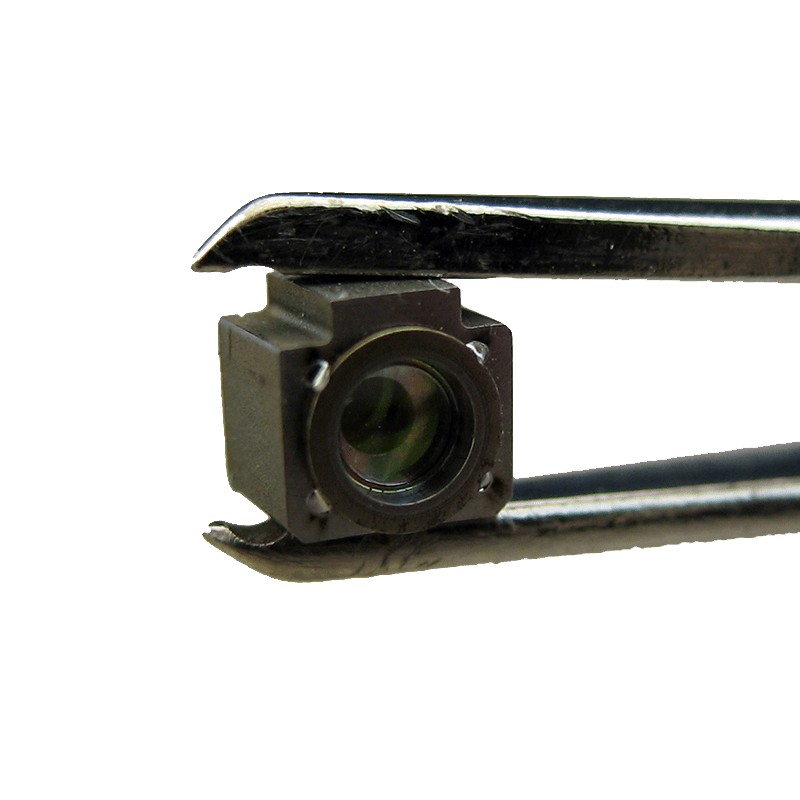

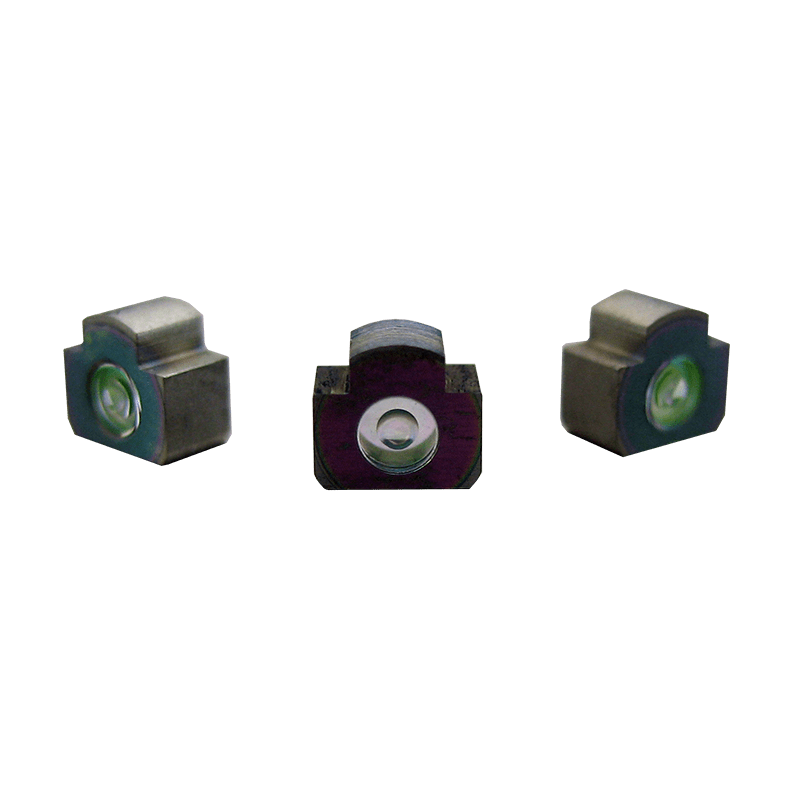

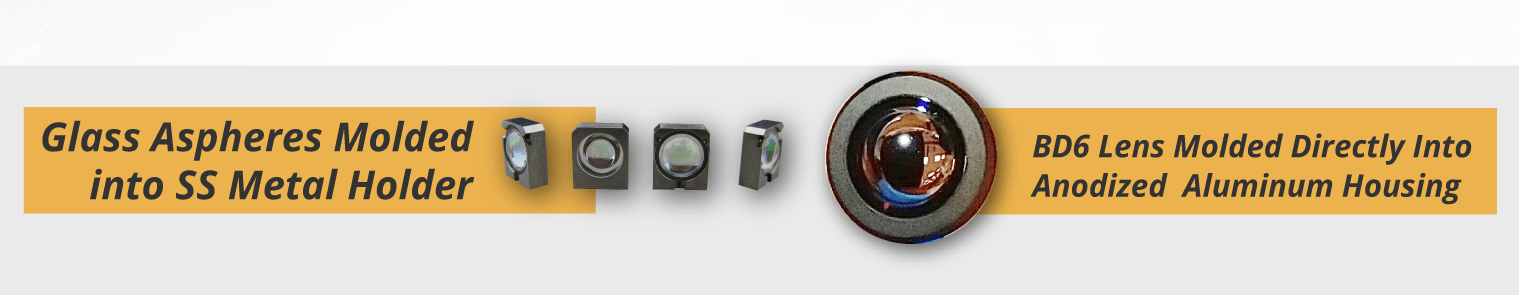

MIP – Optics Molded Directly Into Holders

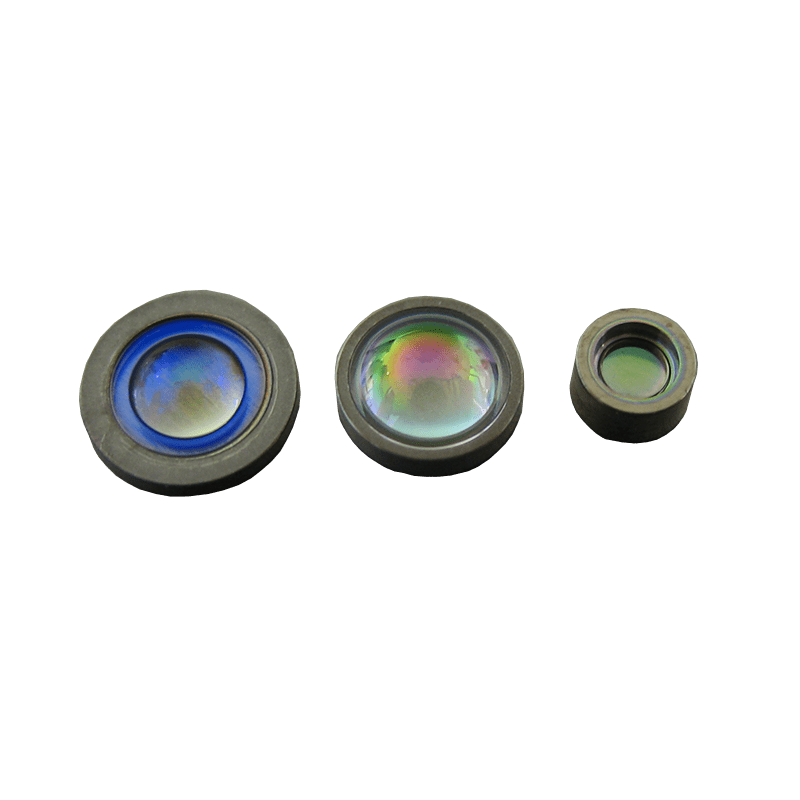

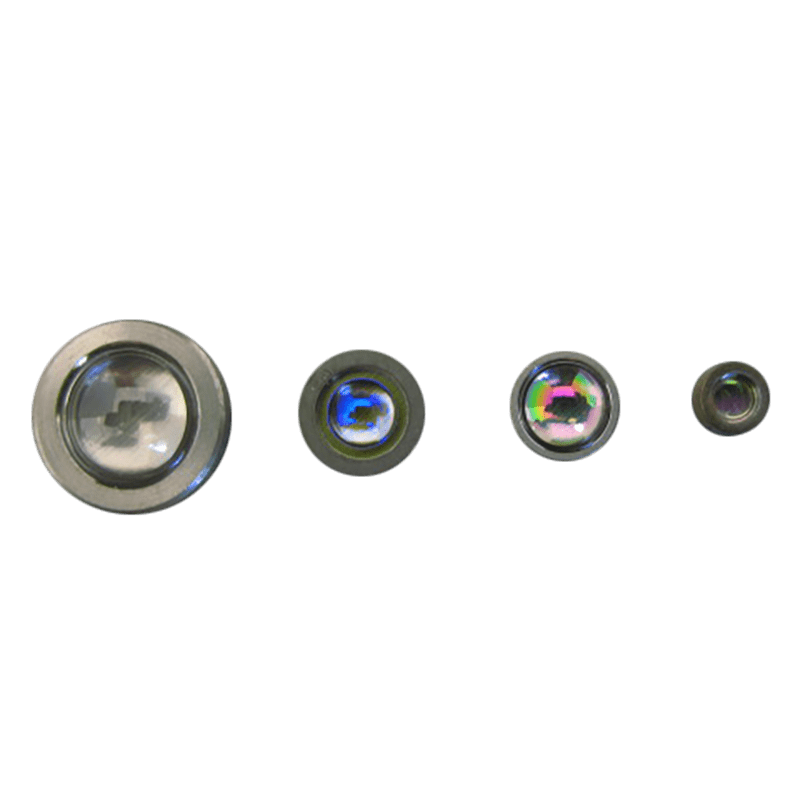

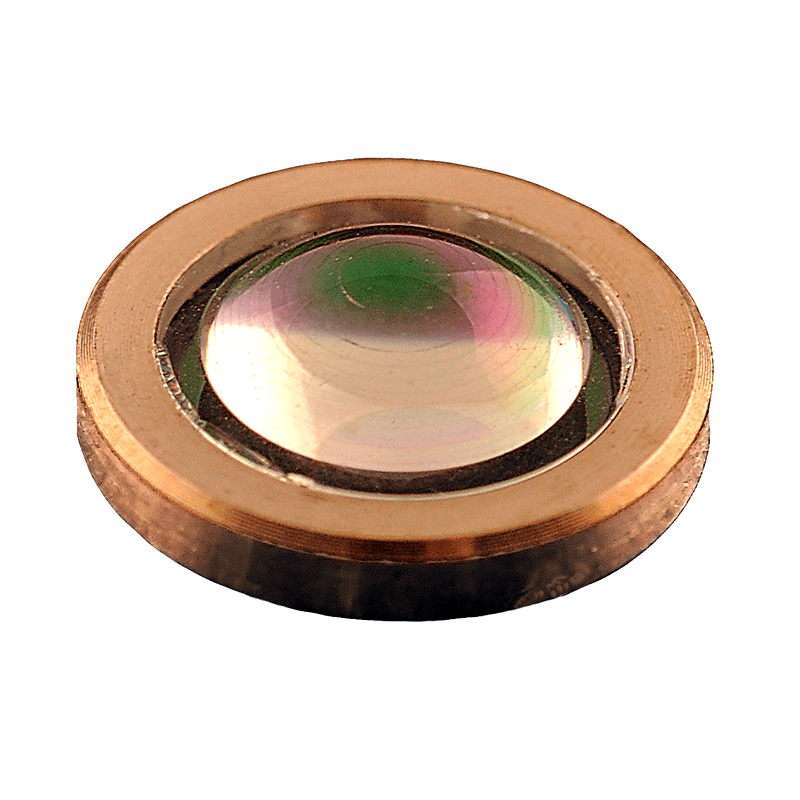

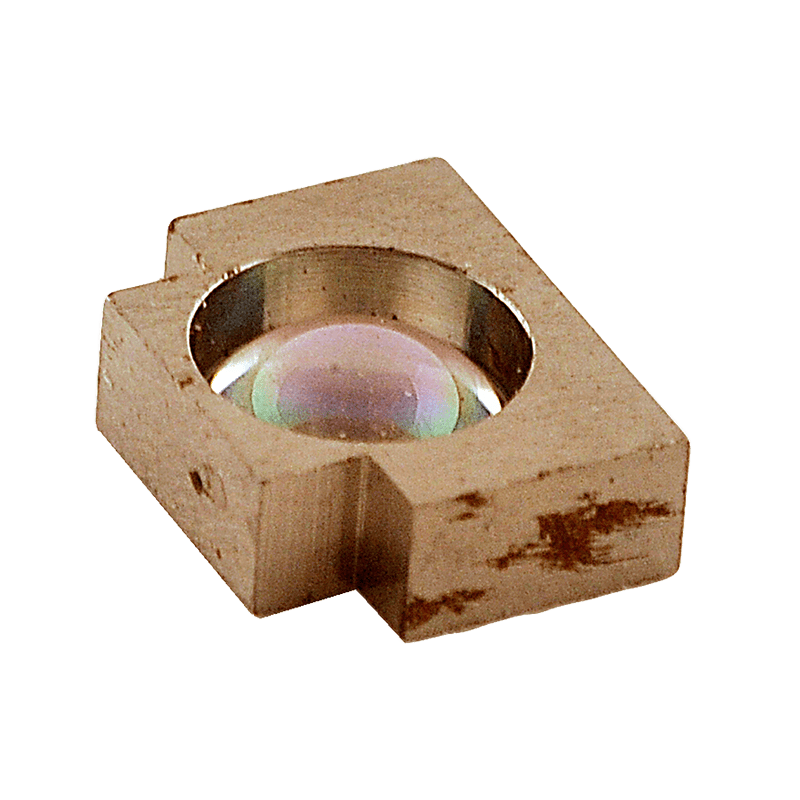

Lenses molded directly into metal holders

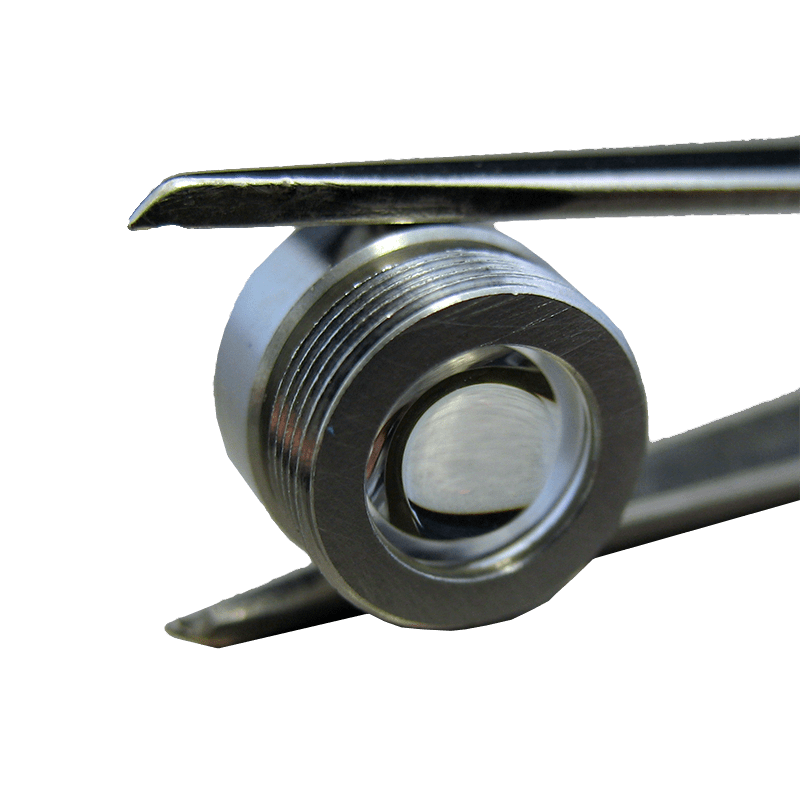

Eliminates the need for Epoxy. Lens can be welded into final position

Creates an hermetic seal, reduces outgassing

Overview

LightPath’s lenses can be molded directly into metallic inserts of stainless steel and aluminum. These metallic housings then simplify your ability to package by welding or soldering. This can be an ideal value add solution for high volume automated assembly or for applications where strict outgassing requirements preclude the use of epoxy adhesives.

Typical Tolerances

| Parameter | Typical Tolerance |

|---|---|

| Focal Length | ± 1% |

| Center Thickness (CT) | ± 0.025 mm |

| Outer Diameter (OD) | ± 0.015 mm |

| Wedge | 4 arcmin |

| Power/Irregularity | 3/1 fringes |

| Surface Roughness | 15nm |

| Surface Quality (scratch/dig) | 40/20 |

| Wave Front Error (RMS) | Diffraction Limited |

| Holder Materials | Alumnium, Stainless Steel |

Molding Process

Precision glass molding (PGM) is a high-temperature, isothermal, compression process conducted within a very controlled environment. LightPath has an extensive innovative history with glass molding and a uses a unique volumetric approach which eliminates the need for any post processing or edging since the exact volume of the glass (preform) is specifically matched to the final lens.

We custom design and manufacture in our Orlando headquarters the lens specific molds and tooling from a variety of materials using a variety of in-house developed techniques. Our molding stations are also designed and customed in house which allows system reproducibility and process control with our single cavity press stations across our global manufacturing locations.

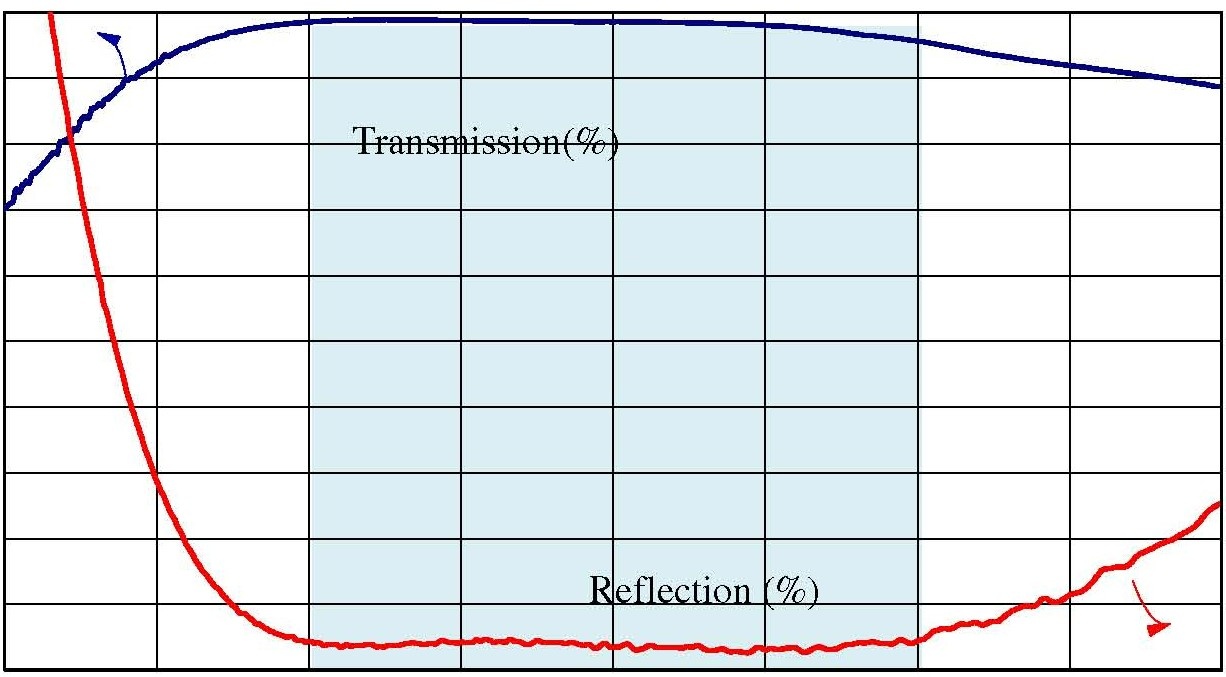

Coatings

Lightpath offers both standard, and custom optical coatings for its infrared windows. Those include Anti Reflective (AR), High Durability AR, Spectral Filters, and protective Diamond Like Carbon (DLC) coatings (for infrared optics).

All three of our global facilities are vertically integrated and include in-house coating and testing. For further information about available coatings please visit our coatings page or contact us.

Contact